Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

MIZHI catenary through shot blasting machines are specially designed for medium and small work piece surface cleaning in large quantity. It adopts single-strand closed-loop transport system. Conveying hooks are loaded with work pieces before moving into the blasting chamber. Work pieces go into the chamber for blasting process at constant speed and frequency. Flexible way and continuous blasting is time & cost effective and this single-strand closed-loop transport system is the best solution to have joint work of transporting and blasting and to be integrated with painting/oil injection line perfectly.

The raw work pieces can either be loaded as a large single component for processing or hung on specific hanger.

Our Advantages

l Space-saving, cost-saving, time-saving

Catenary through shot blasting machine is usually giant but we use ultimately compact design to save space.

Constant & continuous blasting process with high efficiency saves abrasive costs with reliable performance of cleaning and dedusting.

Workable integration into existing production line and joint work with painting line saves production time.

l Reliable quality & long lifespan

Shot blasting chamber is completely engineered of manganese steel plates with thickness between 6 and 10 mm. The blast chamber up to a certain models is welded in one piece, making the machines extremely tight and sturdy. For optimum wear protection, the area exposed to the blast stream is lined with replaceable protective plates that are constructed in manganese steel. These overlapping liners are not bolted on but hung with a special system.

l Customizable machine size

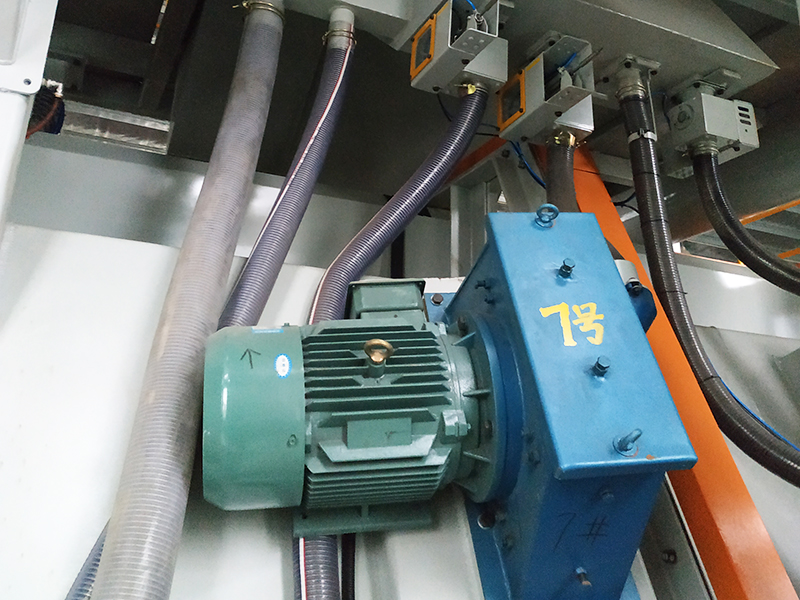

This type of machine is available in more design configurations and capacity sizes to adapt to low or high production parts requirements. The machine size, the number and power of the wheel blasters vary considerably depending on the different work pieces as well as expectations of result and efficiency.

l High-efficiency transport system

Single-strand closed-loop transport system. Work pieces go into the chamber for blasting process at constant speed and frequency. Flexible way and continuous blasting is time & cost effective and this is the best solution to have joint work of transporting and blasting and to be integrated with painting/oil injection line perfectly.

l Sealing system

Blasting sealing: rubber segments are equipped at the roller conveyor inlet & outlet and the blasting chamber to keep the machine nearly 100% tight and prevent accidents of shot spillage.

l Smart PLC

All process parameters of work pieces blasting can be configured and saved in PLC control unit, in the result that repeat input, repeat pushing different buttons are completely unnecessary. This means, much shorter time of parameter configuration, much less working hours of operator and high efficiency.

Smart communication with built-in 3D guiding technology UI and 7 Inch colorful touch screen for safe operation, easy maintenance.

l Environment protection

Great importance is attached by MIZHI to environment protection: noise and dust emission. We adopt high-end methods to reduce noise to 85DB and dust emission concentration to less than 50mg/m3 (these results can be even better with higher standard of configurations).

l Thorough blasting effect

To achieve complete coverage, this machine is usually equipped with 8-16 blast wheels. With this number of blast wheels, every work piece in the blasting chamber will be thoroughly treated from each side and this keeps high efficiency on continuous coming work pieces in large quantity.