Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

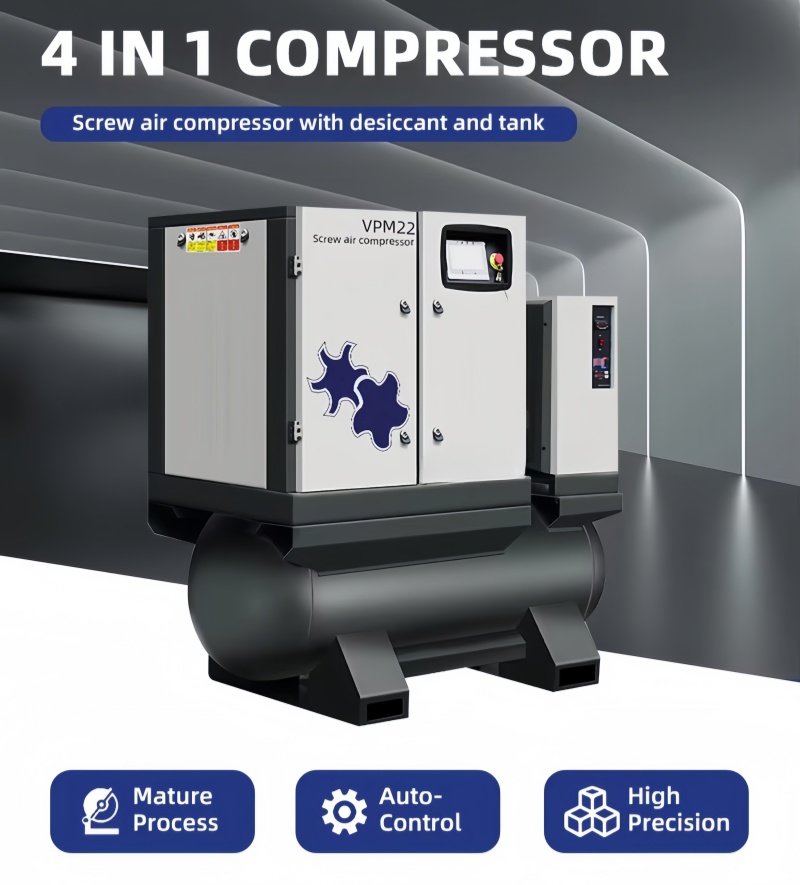

1.Name:Screw Inverter Air Compressor

2.Model:MZ-VPM22

3.Power:22KW

An inverter air compressor operates by using a variable frequency drive (VFD) to control the speed of the motor. This allows the compressor to adjust its output based on the actual demand for compressed air. Unlike traditional compressors that run at a fixed speed and cycle on and off, inverter compressors can continuously vary their speed to maintain a consistent air pressure. This results in more efficient energy use and reduced wear on the motor.

Applications

1.Residential and Commercial Air Conditioning: Inverter compressors are widely used in air conditioning systems for homes and commercial buildings. They provide precise temperature control, reducing energy consumption and maintaining a comfortable environment.

2.Commercial Refrigeration: Supermarkets, restaurants, and food storage facilities benefit from the consistent temperature control offered by inverter compressors. This helps to keep food fresh for longer periods and reduces operational costs.

3.Automotive Air Conditioning: Modern electric and hybrid vehicles often use inverter compressors to provide efficient cooling without placing excessive load on the electrical system. This is crucial for extending battery life and improving overall fuel efficiency.

4.Industrial and Commercial Cooling Systems: In large industrial settings such as warehouses, factories, and data centers, inverter compressors are used in HVAC systems to manage varying cooling demands efficiently.

5.Specialized Applications: Inverter compressors are also used in off-grid and renewable energy-powered cooling systems, such as those powered by solar energy. Their low energy consumption makes them ideal for remote areas or mobile cooling solutions.

Efficiency

6.Energy Savings: Inverter compressors are significantly more energy-efficient than traditional fixed-speed compressors. They can operate at lower speeds for extended periods, reducing energy consumption by up to 30-50%. This not only lowers electricity bills but also reduces the carbon footprint associated with air conditioning use.

7.Precise Temperature Control: The variable speed of inverter compressors allows them to respond quickly to temperature changes, maintaining a more consistent indoor environment. This eliminates uncomfortable temperature fluctuations and ensures a comfortable space.

8.Reduced Noise Levels: Inverter compressors operate more quietly than traditional compressors. The absence of frequent start-stop cycles reduces noise, making them suitable for residential and commercial settings where quiet operation is important.

9.Extended Lifespan: The smooth and continuous operation of inverter compressors reduces mechanical stress and wear on the motor. This leads to a longer lifespan and lower maintenance costs over time.

Working Principle

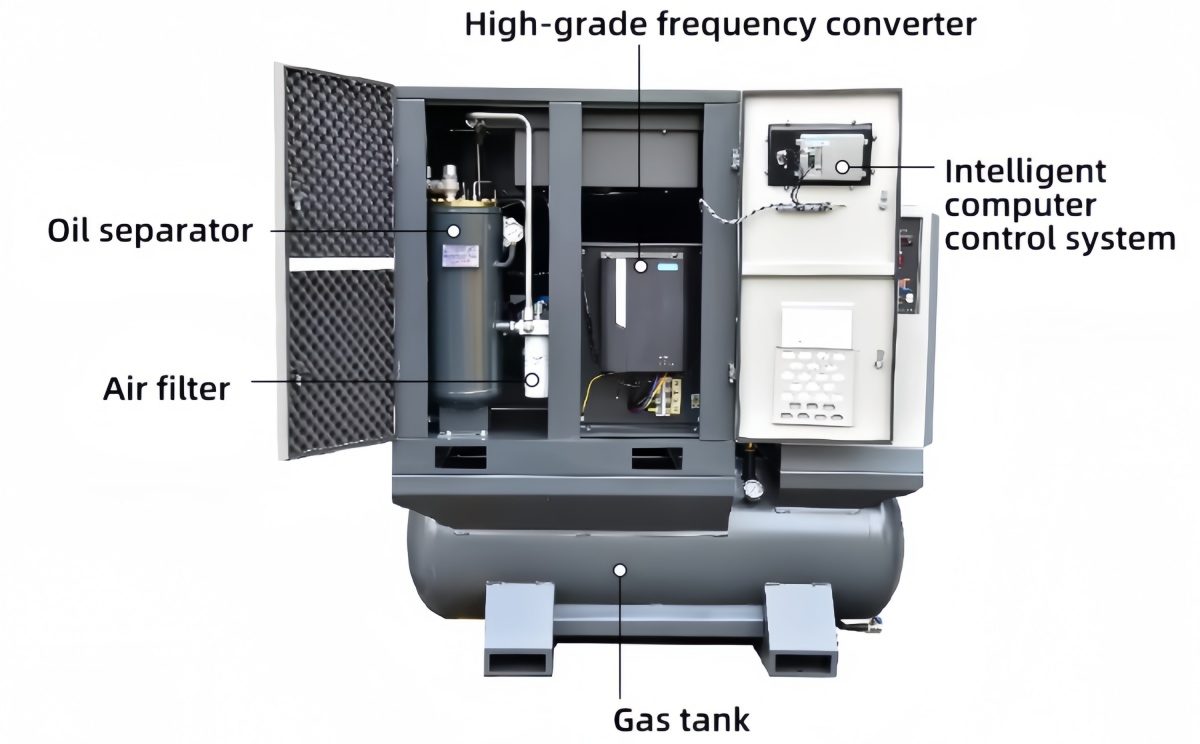

A screw air compressor is a type of rotary compressor that uses two interlocking screws (rotors) to compress air. The working principle can be divided into three main stages: intake, compression, and exhaust.

Intake Process:

1.The motor drives the male rotor to rotate, and the female rotor rotates in sync with the male rotor through a gear mechanism or direct meshing. The spiral grooves on the rotors form new cavities during rotation, creating space for gas intake.

2.At the intake port, the pressure inside the compressor is lower than the external atmospheric pressure, causing gas to be drawn into the cavities between the male and female rotors.

Compression Process:

1.As the rotors continue rotating, the cavity between them begins to shrink, compressing the gas trapped inside. The volume of the cavity decreases, increasing the pressure and temperature of the gas.

2.For oil-injected screw air compressors, oil is injected into the compression chamber through nozzles during compression. The oil mixes with the gas to provide cooling, sealing, lubrication, and noise reduction.

Exhaust Process:

1.When the cavity volume rotates to the exhaust port, the pressure of the gas is higher than that in the exhaust pipe, and the gas is rapidly expelled from the compressor.

2.The oil-gas mixture that is expelled first enters the oil-gas separator, where centrifugal force, gravity, and other physical principles separate the lubricating oil from the gas. The compressed air is further purified by post-processing equipment like dryers and filters.