Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Name:Screw Inverter Air Compressor

2.Model:MZ-VPM45

3.Power:45KW

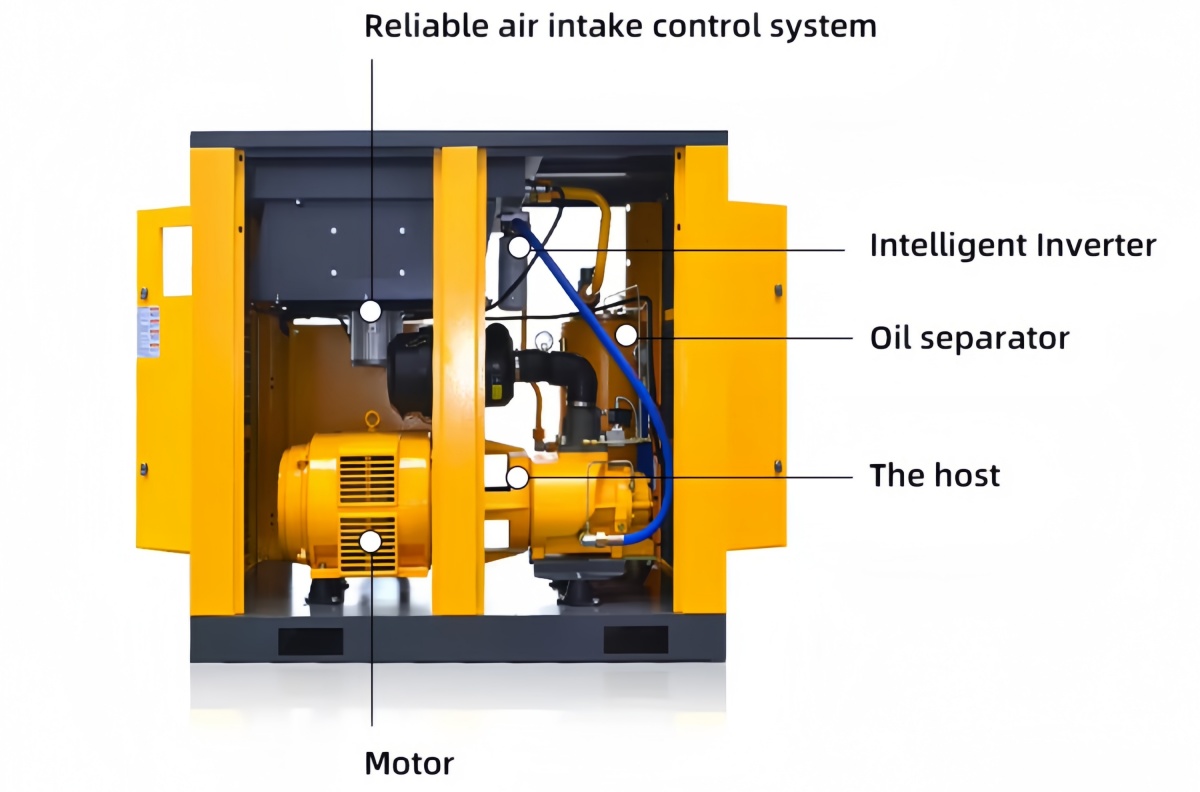

A screw air compressor is a type of rotary compressor that uses two interlocking screws (rotors) to compress air. The working principle can be divided into three main stages: intake, compression, and exhaust.

Working Principle

A screw air compressor is a type of rotary compressor that uses two interlocking screws (rotors) to compress air. The working principle can be divided into three main stages: intake, compression, and exhaust.

Intake Process:

1.The motor drives the male rotor to rotate, and the female rotor rotates in sync with the male rotor through a gear mechanism or direct meshing. The spiral grooves on the rotors form new cavities during rotation, creating space for gas intake.

2.At the intake port, the pressure inside the compressor is lower than the external atmospheric pressure, causing gas to be drawn into the cavities between the male and female rotors.

Compression Process:

1.As the rotors continue rotating, the cavity between them begins to shrink, compressing the gas trapped inside. The volume of the cavity decreases, increasing the pressure and temperature of the gas.

2.For oil-injected screw air compressors, oil is injected into the compression chamber through nozzles during compression. The oil mixes with the gas to provide cooling, sealing, lubrication, and noise reduction.

Exhaust Process:

1.When the cavity volume rotates to the exhaust port, the pressure of the gas is higher than that in the exhaust pipe, and the gas is rapidly expelled from the compressor.

2.The oil-gas mixture that is expelled first enters the oil-gas separator, where centrifugal force, gravity, and other physical principles separate the lubricating oil from the gas. The compressed air is further purified by post-processing equipment like dryers and filters.

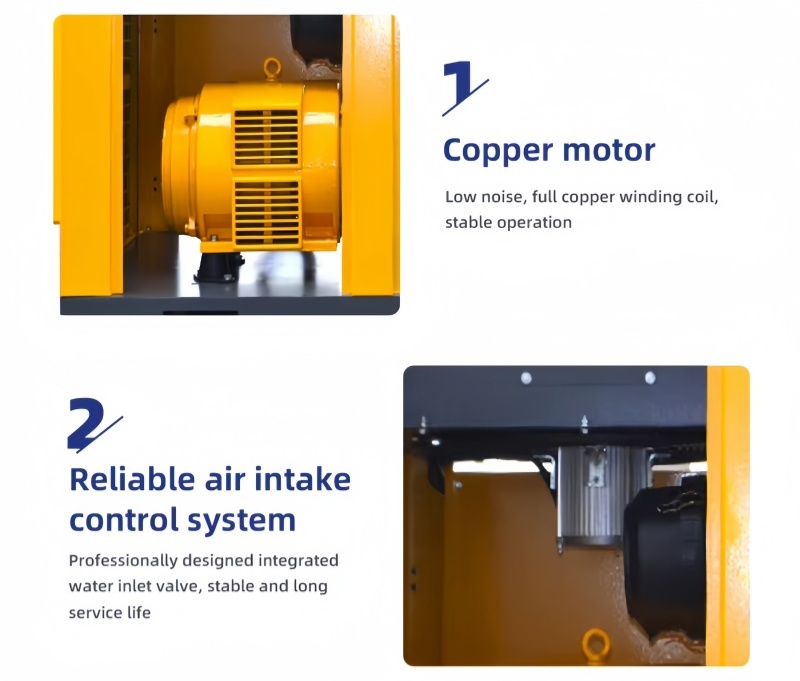

Product Features

1.Energy Efficiency: Screw air compressors are designed to consume less power while providing greater output, making them a cost-effective choice in the long run.

2.Low Noise: Their design minimizes noise, making them suitable for indoor or noise-sensitive environments.

3.Durability: With minimal moving parts and a robust design, screw compressors tend to have longer operational lifespans, reducing the need for frequent replacements.

4.Low Maintenance: Compared to other types of air compressors, screw compressors require less maintenance. Their efficient design and high-quality components ensure minimal wear and tear, reducing downtime and maintenance costs.

5.Extreme Temperature Tolerance: Some models can handle extreme temperatures, from -47°C to 55°C, making them suitable for challenging environments.

6.Compact Design: Screw air compressors have a compact design that saves valuable floor space and maximizes productivity.