Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

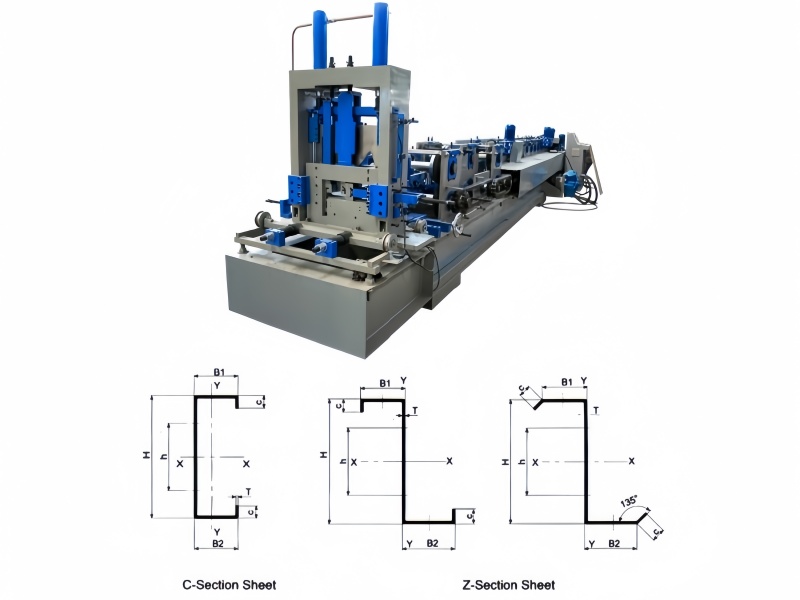

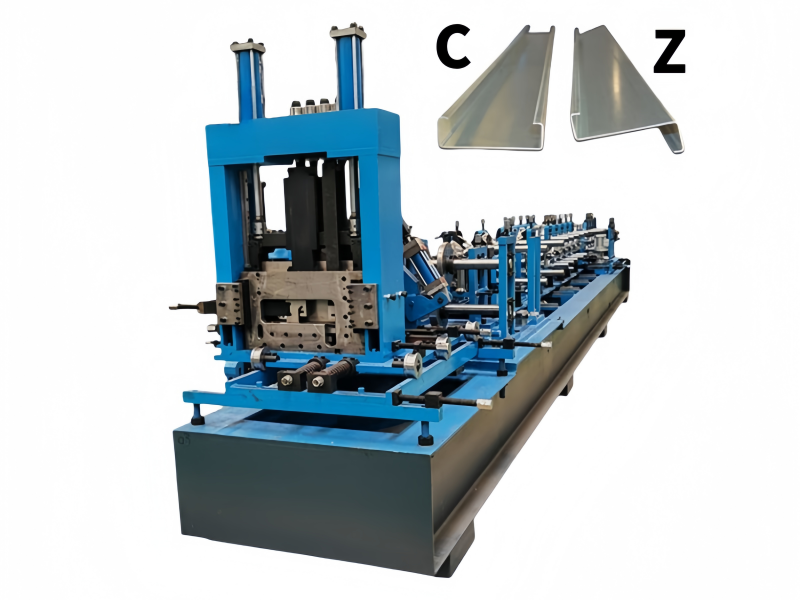

1.Name:C-Section Steel Profile Roll Forming Machine

2.Application: C-Section Steel Profile

3.It can custom-design

A C-Section Steel Profile Roll Forming Machine is a specialized piece of equipment used to manufacture C-shaped steel profiles, which are widely used in construction, particularly for roofing systems and structural applications.

Below is a detailed description of this machine:

Main Components

1.Uncoiling Unit:

The uncoiling unit is designed to handle steel coils. It typically includes a decoiler with a breaking device to manage the feeding of the steel strip. The decoiler can be manual or powered, with capacities ranging from a few hundred kilograms to several tons.

2.Entry Guide and Leveling System:

The entry guide ensures the steel strip is correctly aligned before entering the leveling system. The leveling system, often consisting of multiple rollers, straightens the steel strip to remove any deformities and ensure uniformity.

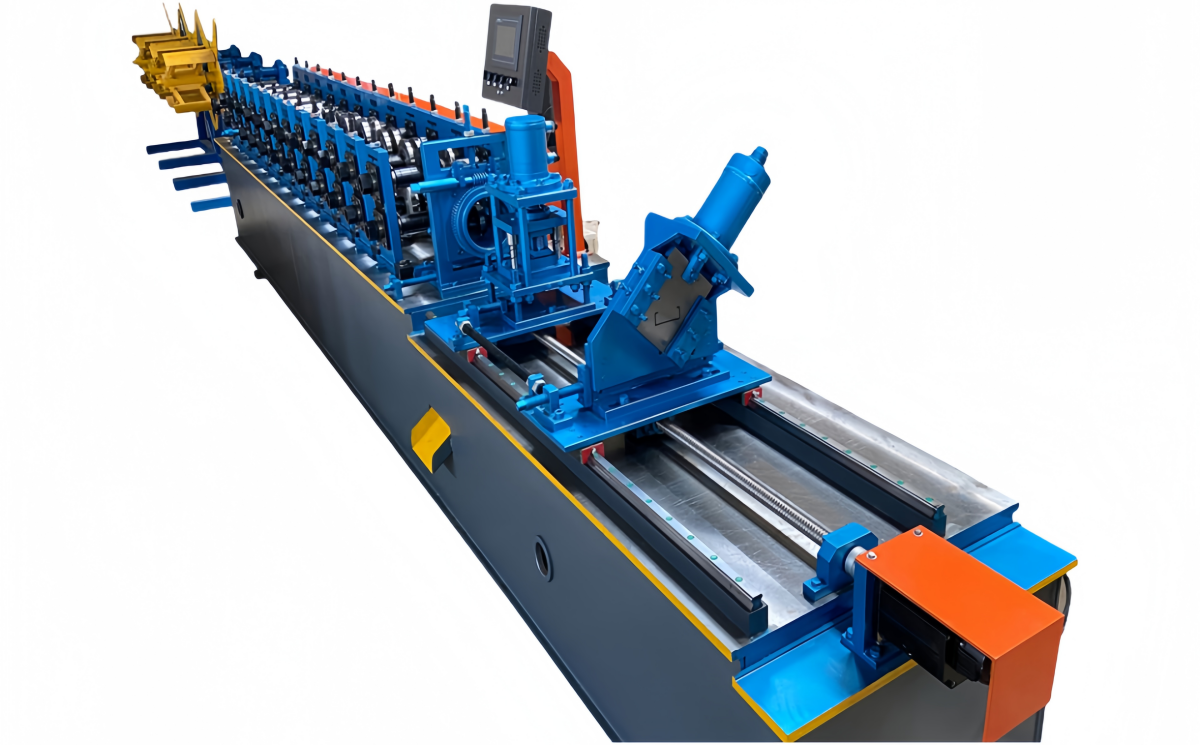

3.Roll Forming Section:

This is the core part of the machine where the steel strip is gradually shaped into a C-section profile through a series of rollers. The rollers are precision-engineered from high-quality materials like GCr15 bearing steel and are heat-treated for durability. The forming process involves multiple channels (typically around 16) to achieve the desired profile.

4.Punching and Cutting Systems:

The machine may include pre-punching and pre-cutting devices for adding holes or making cuts before the final forming process. The cutting system can be hydraulic or mechanical, with options for both pre-cutting and post-cutting depending on the application.

5.Straightening and Output Table:

After forming, the C-section profiles pass through a straightening unit to ensure they are perfectly aligned. The output table or run-out table supports the finished profiles as they exit the machine.

6.Control System:

Modern C-section steel profile roll forming machines are equipped with advanced control systems, typically using PLC (Programmable Logic Controller) and touchscreens for easy operation and adjustment. The control system allows for automatic size changes, production data input, and precise length control.

Technical Specifications

1.Material Compatibility: Suitable for various steel materials, including galvanized steel, hot-rolled steel, and cold-rolled steel.

2.Material Thickness: Typically handles thicknesses ranging from 0.7mm to 3.0mm.

3.Production Speed: Varies from 10m/min to 45m/min, depending on the machine model and configuration.

4.Power Requirements: Generally operates on three-phase power, with voltages ranging from 380V to 415V.

Features and Advantages

1.High Degree of Automation: The machine can automatically adjust sizes and switch between different profiles (e.g., C-section to Z-section) without changing rollers, significantly reducing setup time.

2.Precision and Consistency: The roll forming process ensures high precision and uniformity in the finished profiles, which is difficult to achieve with manual processes.

3.Efficiency: The automated production line reduces labor requirements and increases production efficiency by 5-10 times compared to traditional methods.

4.Safety: The machine design and operation minimize the risk of industrial accidents, especially when compared to manual cutting and bending processes.

Applications

C-section steel profiles produced by these machines are used in a wide range of applications, including:

1.Roofing purlins in metal building systems.

2.Structural supports in construction projects.

3.Components in industrial and residential buildings.

Summary

A C-Section Steel Profile Roll Forming Machine is a highly efficient and automated solution for producing high-quality C-section steel profiles, offering significant advantages in terms of precision, speed, and versatility.