Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

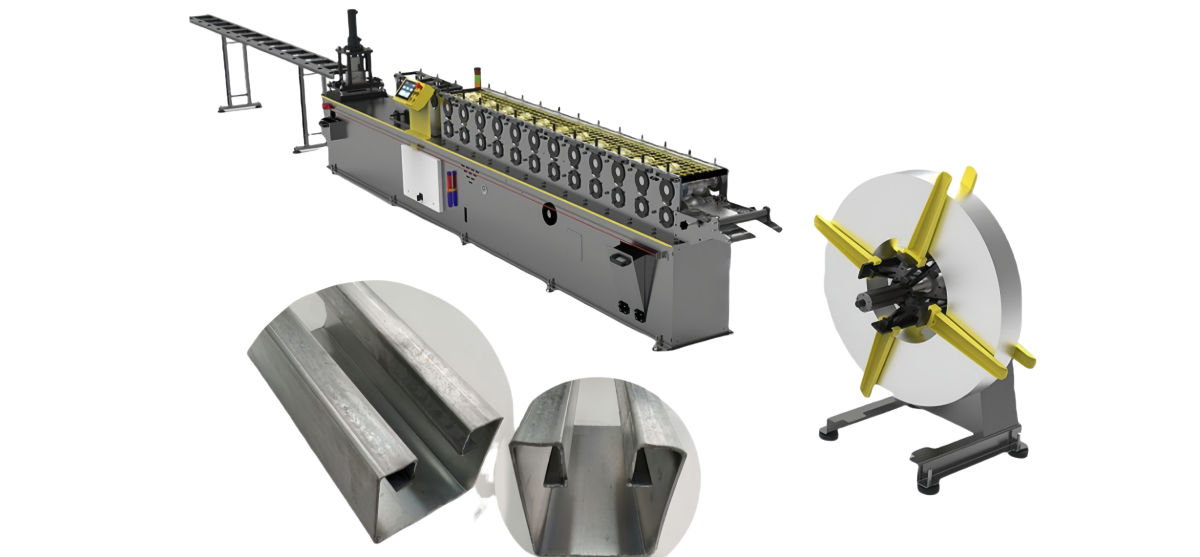

1.Name:Cooling Tower Profile Roll Forming Machine

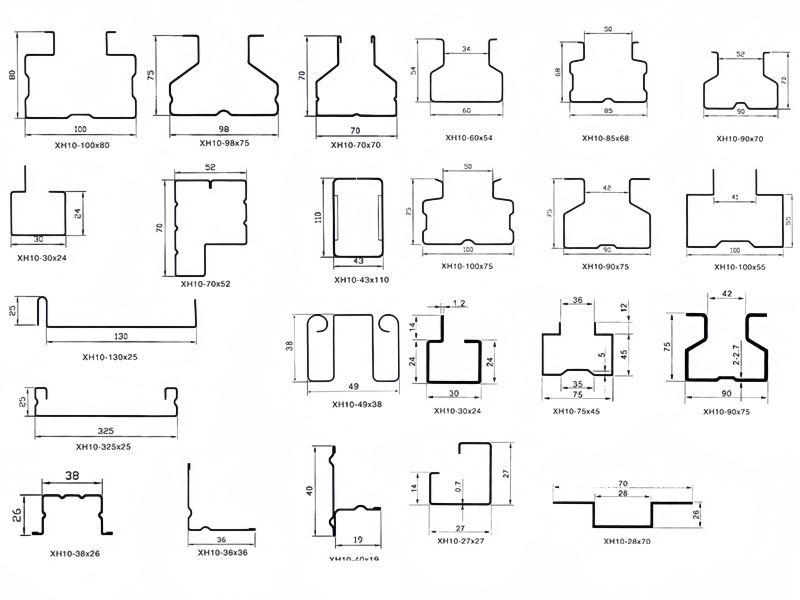

2.Application: Making Cooling Tower Profile

3.It can custom-design

Introduction

A Cooling Tower Profile Roll Forming Machine is a specialized piece of industrial equipment designed to produce profiles for cooling towers, including corner columns, base channels, and other structural components. These machines are essential for the manufacturing of cooling tower parts, which are critical in various industrial applications, such as power plants, HVAC systems, and water treatment facilities.

Key Features and Specifications

1.Material Compatibility: The machine can process galvanized sheets and paint-free sheets with thicknesses ranging from 0.8mm to 2.0mm.

2.Production Speed: Capable of producing profiles at a speed of 0-6 meters per minute.

3.Power Consumption: The equipment typically requires 30-45KW of power.

4.Profile Length: The machine can produce parts with lengths ranging from 1000mm to 3000mm.

5.Control System: Equipped with a PLC programmable monitoring system, which ensures high precision and automation.

Process Flow

The production process of a Cooling Tower Profile Roll Forming Machine typically includes the following steps:

1.Unwinding: The metal coil is unwound and fed into the machine.

2.Punching: Multi-station combined bed punching is performed to create holes or notches as required.

3.Roll Forming: The metal strip is shaped into the desired profile through a series of rollers.

4.Hydraulic Cutting: The formed profile is cut to the specified length using hydraulic cutting technology.

5.Receiving: The finished profiles are collected at the end of the production line.

Applications

1.Cooling Tower Construction: Used to produce base channels, corner columns, and other structural components for cooling towers.

2.Industrial Applications: Suitable for manufacturing parts for power plants, HVAC systems, and water treatment facilities.

Advantages

1.High Precision: Ensures uniform dimensions and high-quality profiles.

2.Efficiency: High production speed and automated processes reduce labor costs and increase output.

3.Versatility: Capable of producing various profiles to meet different industrial requirements.

4.Durability: Robust construction with high-quality materials ensures long-term reliability.

Manufacturer Information

MIZHI is a leading manufacturer of roll forming machines. Established in 2007, the company specializes in the research and development, processing, manufacturing, and sales of cold bending equipment.

MZIHI offers a wide range of products and services, including professional design, engineering cost analysis, roll design, and custom-made precision rolls.

Conclusion

A Cooling Tower Profile Roll Forming Machine is an essential tool for the efficient and precise production of cooling tower components. With its high precision, efficiency, and versatility, it is well-suited for various industrial applications. Reputable manufacturers like Foshan ACU Machinery Equipment Co., Ltd. provide reliable and high-quality solutions to meet the specific needs of customers.