Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Coil Width: 100-600 mm

2.Material Thickness: 0.5-4.5 mm

3.Coil Weight: 3000kgs

4.Inner Diameter: 450-530mm

5.Outer Diameter: 1200mm

6.Speed: 16m/min

7.Applicable Material:Raw Material Type: Hot-Rolled Metal steel, Cold-Rolled Metal steel, Galvanized Metal steel ,Stainless Steel etc.

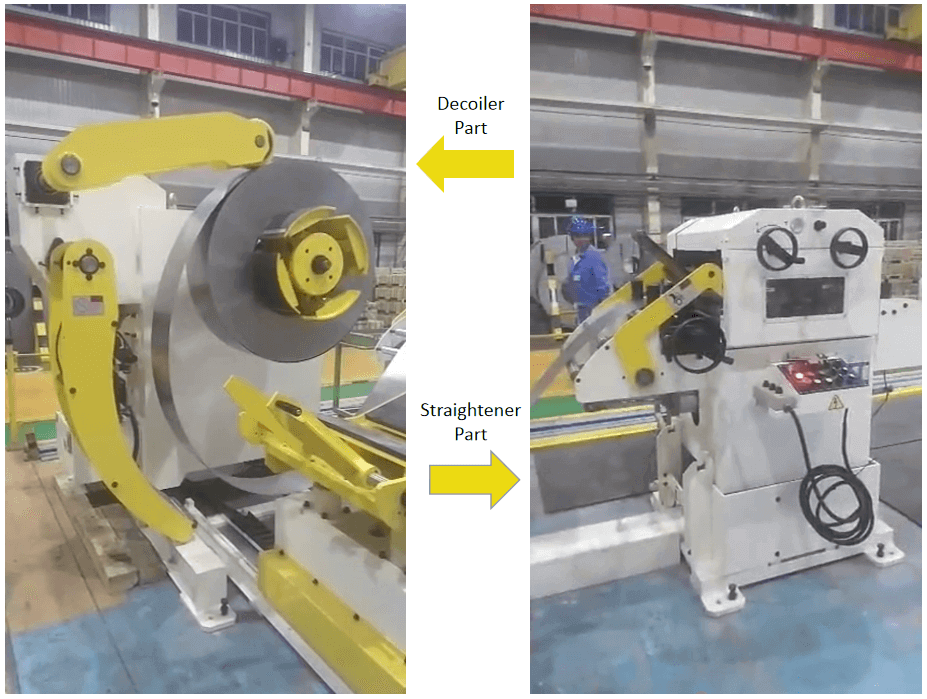

Hydraulic Decoiler straightener machine is in the short space design were designed to meet the needs of customers with limit space. It’s smart and easy to move and install it.

Hydraulic Decoiler Straightener assembly decoiler and straightener machine 2 in 1 ,It could effectively save the installation space,reduce precision material transition segment in the process of straightening,then could maximize develop of the machine performance.

It can uncoiling and straightening the metal sheet coil from width 100-800mm, and thickness from 0.5-4.5mm, coil weight from 1000kgs to 3000kgs.

It’s suitable for hardware stamping, electrical products, computer shell and so on.

With pneumatic pressure on upper and lower straightener roller distance adjusting and worm gear adjusting, it can achieve precision straightening performance for many different kind of metal sheet material.

It is a compact solution for systems requiring sensitive preliminary straightening before being driven. You may have a driver or a driver with straightener designed for standard sheet metal type.

If additional straightening is required before switching to a new product line or in case of sheet metal change, decoiler with straightener will be the solution for you. This machine is preferred as an additional solution to currently running systems, and whenever there is a foreseen sheet change. By using this type of decoiler, it is possible to provide openers which can open the sheets in different sensitivities without interfering with the driver.

Coil Car

Coil car is one of the optional for the customer, It is installed on the side of the decoiler part, and can automatically feed the coil into the straightener machine accurately and fastly.

The surface of Coil car is V type with sandblasting surface treatment process, it can protect the material surface from scratching and the main function is assisting loading the coils on the spindle rack of decoiler parts.

Adjustable coil guide baffles prevent narrow coils from dumping

Coil car move forward and backward by Hydraulic motor

Coil car lifting up and down smoothly by hydraulic cylinder

Share the power with decoiler machine

Decoiler Parts

The motor control cabinet of the material combined decoiler straightener are relatively independent,also they use their own frequency converter,that means it could take more effectively protecting the machine to make sure there will not distorted when it subjected to other external forces.

The drive system of the straightening machine are universal joint and gear transmission,that could effectively avoid the material’s damage from passive wheel rotation.

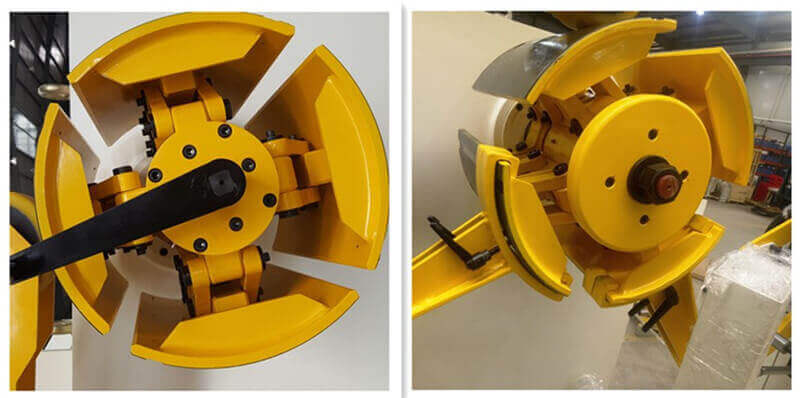

Manual Expansion Hydraulic Expansion

High Precision Straightening Parts

The straightening wheel have dial indicator,it could found the leveling points quickly. It strengthen roll stiffness according with straightening back pressure wheel,then make the straightening effect better.

The service life of the machine will be longer with adding the lubrication system.OEM accepted,could change the rack load,correction parameters and also could according to the need to make power or unpowered pressure arm hydraulic expansion,etc.

Worm Gear GCr15 Straightening Rolls, Hardness HRC60

Coil Input Supporting Arm Outlet Rolls

Model:GL-H | ||||

Model | GL-300H | GL-200H | GL-500H | GL-600H |

Material Width | 300 | 200 | 500 | 600 |

Coil Thickness | 0.5-4.5mm | |||

Straightener Roller | Ø68mm*7pcs(4 On Top/3 On Bottom) | |||

Coil I.D. | Φ450-530 mm | |||

Coil O.D. | Φ1200 mm | |||

Coil Weight | 2000 kg | 2000kg | 3000 kg | 3000 kg |

Uncoiler Motor | 1.5kw | |||

Straightener Motor | 2.2kw | 2.2kw | 4.4kw | 4.4kw |

Roller pressing way | Pneumatic rod | |||

Roller adsjuting way | Eccentric turbine worm adjusting | |||

Inverter | Delta,Taiwan | |||

Expansion Way | Manual or Hydraulic | |||

Feeding speed | 16m/min | |||

Pressing arm | Hydraulic | |||