Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

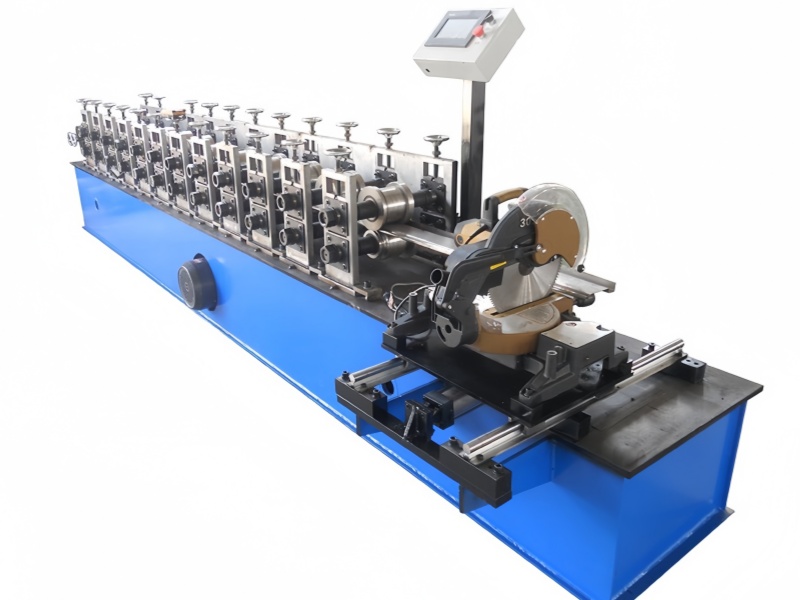

1.Name:Door Roll Forming Machine

2.Application: Making Door Profile

3.It can custom-design

Introduction

A Door Roll Forming Machine is a specialized piece of manufacturing equipment designed to produce door components, such as door frames, panels, and rolling shutter door slats, with high precision and efficiency. This technology has revolutionized door manufacturing by offering consistent quality, reduced labor costs, and increased production rates.

How Door Roll Forming Machines Work

The operation of a Door Roll Forming Machine involves feeding a flat metal strip through a series of rollers and tooling stations. The metal strip undergoes incremental bending and shaping, gradually forming into the desired door component profile. The process is continuous, allowing for high-volume production with minimal material wastage.

Key Components

1.Decoiler: Unwinds the metal coil to feed the material into the machine.

2.Leveling System: Ensures the metal strip is flat before forming.

3.Roll Forming Stations: Gradually shape the metal strip into the desired profile through a series of rollers.

4.Punching/Notching Device: Creates holes or notches in the profile as required.

5.Cutting Device: Cuts the formed profile to the specified length.

6.Output System: Collects the finished profiles, with options for manual support or automatic stacking.

7.PLC Control System: Manages the entire production process, allowing for automation and precision.

Applications

1.Residential Buildings: Produces door frames and panels for homes.

2.Commercial Spaces: Manufactures door components for offices and retail stores.

3.Industrial Structures: Creates robust door solutions for warehouses and factories.

4.Infrastructure Projects: Used in the production of door frames for public buildings and facilities.

Types of Door Roll Forming Machines

1.Single-Profile Machines: Ideal for producing a specific door design.

2.Multi-Profile Machines: Offer versatility by accommodating multiple designs.

3.Automated Systems: Integrate various processes such as cutting, punching, and embossing, further streamlining production.

Key Features

1.Material Compatibility: Works with various metals, such as steel or aluminum.

2.Roller Quality: High-quality rollers ensure precise forming.

3.CNC Systems: Enable easy programming and adjustment for different profiles.

4.Servo Feeding: Ensures accurate speed and tension control.

5.Quick Die Change: Allows for faster profile changeovers.

6.Touchscreen HMI: Provides a user-friendly interface for production management.

Working Process

1.Material Feed: The metal coil is unwound and fed into the machine.

2.Leveling: The metal strip is flattened to ensure uniformity.

3.Forming: The strip is shaped into the desired profile through multiple rolling stations.

4.Punching/Notching: Holes or notches are created as required.

5.Cutting: The formed profile is cut to the specified length using computer-controlled cutting units.

6.Output: The finished profiles are collected on an output table or automatic stacker.

Benefits

1.High Precision: Ensures uniform dimensions and geometries, enhancing assembly quality.

2.Increased Efficiency: High-speed production capabilities boost manufacturing output.

3.Cost Savings: Reduces manual labor and material wastage.

4.Customization: Can produce a variety of profiles and sizes to meet specific requirements.

Choosing the Right Machine

When selecting a Door Roll Forming Machine, consider factors such as production volume, door design complexity, available space, budget, and the ability to adapt to future design changes. Reputable manufacturers like Botou Xianfa, Jingxing Rollforming, and Shanghai Metal Corporation offer customizable solutions to meet specific needs.

A Door Roll Forming Machine is an essential tool for modern door manufacturing, providing efficiency, precision, and flexibility to meet various production requirements.

Parameter | Specification |

Material Thickness | 0.5 mm to 2 mm (cold-rolled steel, galvanized steel) |

Material Width | Up to 1200 mm |

Production Speed | Up to 30 m/min |

Cutting Accuracy | ±1.0 mm |

Main Motor Power | 7.5 kW to 18.5 kW |

Roller Material | GCr15 with heat treatment (HRC58-62°) |