Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

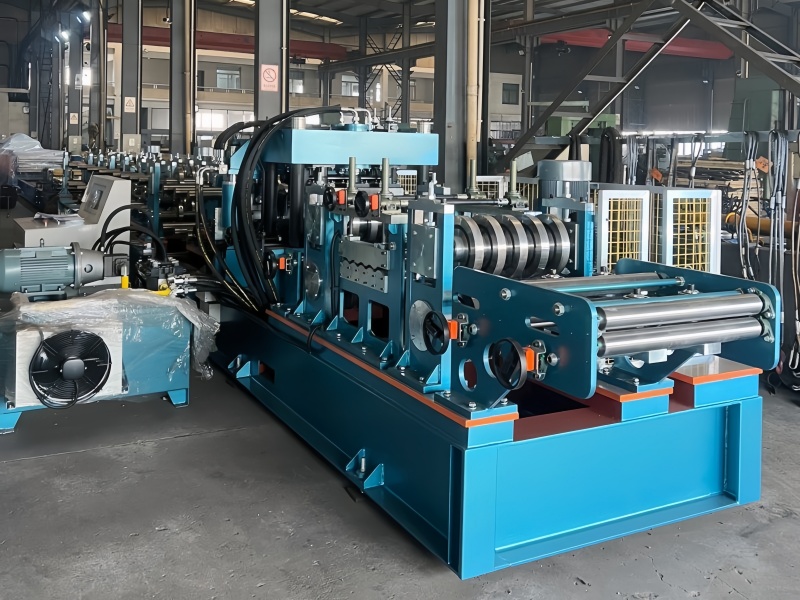

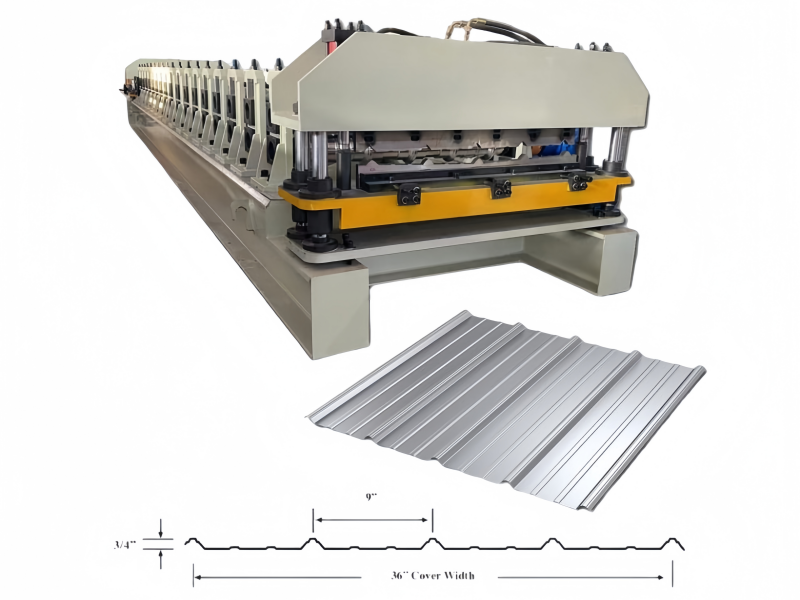

1.Name:Frame Profile Roll Forming Machine

2.Application: Making Frame Profile

3.It can custom-design

Detailed Description

A Frame Profile Roll Forming Machine is a specialized industrial equipment designed to continuously shape metal coils or sheets into precise frame profiles (such as door/window frames, structural supports, or metal trims) through a series of rolling stations. This automated process ensures high efficiency, consistency, and customization for various industrial applications.

Key Features

1.Material Compatibility

Processes steel, aluminum, galvanized steel, or stainless steel coils (typical thickness: 0.2–3.0 mm).

Handles widths ranging from 20 mm to 600 mm, depending on design requirements.

2.Roll Forming Process

Uncoiler: Feeds the metal coil into the machine.

Leveling Unit: Flattens the coil to eliminate distortions.

Roll Stations: Progressive sets of rollers gradually bend the metal into the desired profile shape.

Cutting System: Uses hydraulic/pneumatic punches or flying saws to cut profiles to precise lengths.

Output Conveyor: Transports finished frames for stacking or further processing.

3.Automation & Control

PLC System: Programs profile dimensions, speed (5–30 m/min), and cutting length.

HMI Interface: Allows operators to monitor and adjust parameters in real time.

Servo Motors: Ensure high precision in forming and cutting.

4.Customization Options

Adjustable rollers to produce multiple frame profiles (e.g., C-sections, U-channels, or complex geometries).

Optional add-ons: pre-punching units, embossing, or surface coating systems.

Why Choose a Frame Profile Roll Forming Machine?

1.Cost-Effective: Reduces labor and material costs vs. traditional fabrication.

2.Scalable: Ideal for mass production with consistent quality.

3.Versatile: Adaptable to industry-specific profile designs.

For custom requirements (e.g., non-standard profiles or automation integration), manufacturers like MIZHI Technology offer tailored solutions.

Applications

1.Construction: Door/window frames, curtain walls, and steel studs.

2.Automotive: Vehicle body reinforcements and trim parts.

3.Furniture: Metal frames for cabinets or shelving.

4.HVAC: Duct supports and brackets.

Advantages

✔ High Precision: Tolerances as tight as ±0.1 mm.

✔ Efficiency: Produces up to 30 meters per minute with minimal material waste.

✔ Durability: Hardened alloy rollers withstand long-term use.

✔ Low Maintenance: Modular design for easy part replacement.

Technical Specifications (Example)

Parameter | Details |

Material Thickness | 0.2–3.0 mm |

Profile Width | 20–600 mm |

Speed | 5–30 m/min |

Power Supply | 380V/50Hz or customized |

Control System | PLC + Touchscreen HMI |