Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

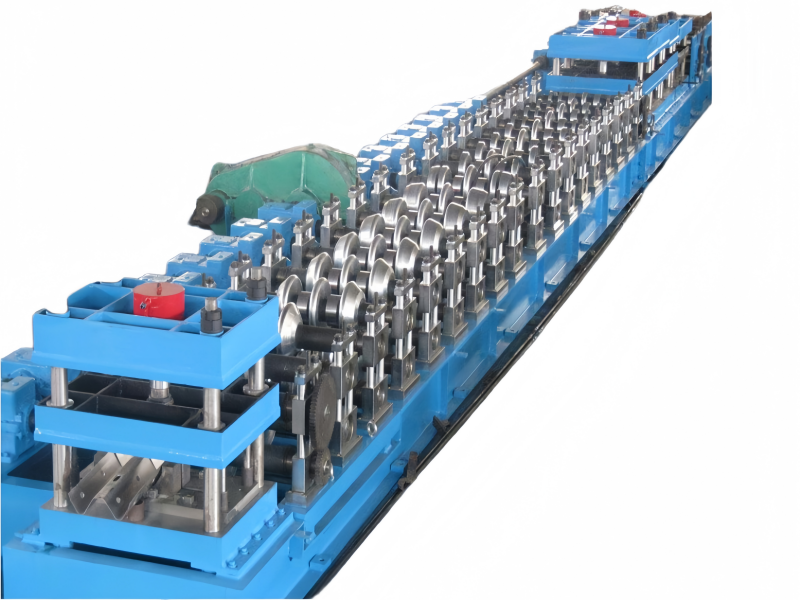

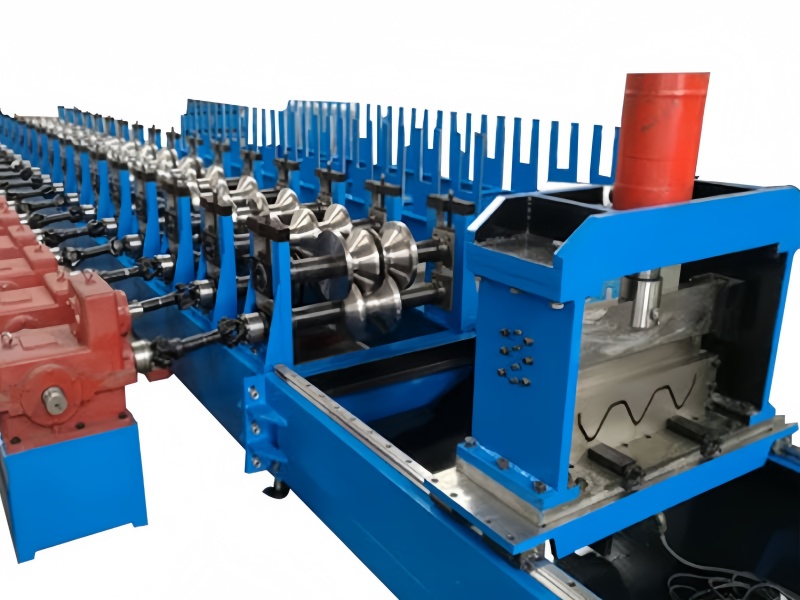

1.Name:Highway Guardrail Roll Forming Machine

2.Application: Making Highway Guardrail

3.It can custom-design

The Highway Guardrail Roll Forming Machine is a specialized industrial device designed to produce high-quality guardrails for highway safety. These machines are essential for manufacturing W-beam guardrails, flex-beam guardrails, thrie-beam guardrails, and box beam guardrails, which are critical for preventing traffic accidents and minimizing damage.

Main Components

1.Decoiler: This component unwinds the steel coil and feeds it into the machine. It can be hydraulic or manual, with a loading capacity of up to 10 tons and coil diameters ranging from 480mm to 1800mm.

2.Leveling Unit: This section flattens the steel strip to ensure even feeding. It typically includes multiple rollers for precise leveling.

3.Punching System: This part punches holes or shapes into the steel strip as it enters the roll forming section. It can be hydraulic or use a punching press.

4.Roll Forming Section: This is the core of the machine, where the steel strip is gradually shaped into the desired guardrail profile through a series of rollers. Machines can have 12 to 18 forming stations.

5.Cutting System: This component cuts the formed guardrail to the specified length, typically using hydraulic shearing.

6.Control System: Modern machines are equipped with PLC control systems, touchscreens, and servo drives for automation and monitoring.

Real Case Examples

Case A: A guardrail roll forming machine set up in China for government projects, producing both W-beam and thrie-beam guardrails with a line speed of 8 meters per minute.

Case B: An affordable post-cut flow chart machine exported to Russia and Saudi Arabia, offering lower prices while ensuring perfect quality.

Case C: A machine developed for Turkish customers, meeting the EN 1461:2009 standard, with a shrink mold at the end of the production line.

Technical Specifications

1.Material Compatibility: Suitable for galvanized steel, mill steel, and carbon steel with thicknesses ranging from 2.7mm to 4mm.

2.Forming Speed: Typically ranges from 10 to 15 meters per minute.

3.Roller Material: High-quality steel such as GCr15 with heat treatment (hardness HRC58-62°) to ensure durability.

4.Power Supply: 380V, 50Hz, 3-phase.

5.Machine Structure: Heavy-duty forged iron stations with gearbox or chain drive options.

Applications

Highway guardrails are essential for traffic safety, preventing vehicles from hitting roadside obstacles, veering off the road, or crossing into oncoming traffic. They are used on highways, expressways, parking lots, and other high-risk areas.

The Highway Guardrail Roll Forming Machine is a versatile and efficient solution for producing high-quality guardrails that meet international safety standards. Its precision, customization capabilities, and durability make it a valuable asset in the highway construction industry.

Industry Standards

Guardrail roll forming machines can produce products that meet various international standards, including:

1.AASHTO M180 (American standard)

2.RAL RG620 (German standard)

3.BS EN-1317 (European standard)

4.AS/NZS 3845:1999 (Australian standard)

5.EN 1461:2009 (Turkish standard).

Advantages

1.High Precision: CNC machining of rollers ensures precise shaping.

Customization: Machines can be configured to produce different guardrail profiles and meet specific standards.

2.Efficiency: Automated processes increase production speed and reduce labor costs.

3.Durability: High-quality materials ensure long-term reliability.