Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

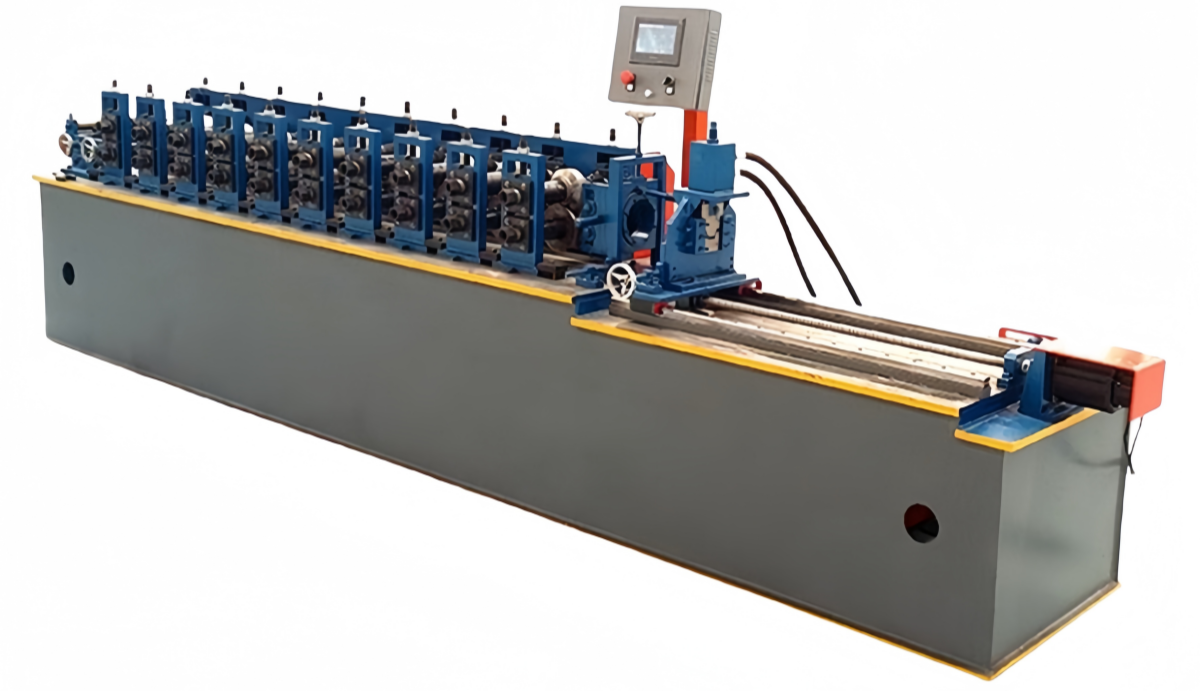

1.Name:Ligh Steel Keel Roll Forming Machine

2.Application: Making Ligh Steel Keel

3.It can custom-design

Introduction

A Light Steel Keel Roll Forming Machine is a specialized piece of equipment designed to produce light steel frames and profiles for construction applications. These machines are widely used to manufacture metal studs, tracks, furring channels, and other structural components for walls, ceilings, and floors. The products are known for their high strength, lightweight, and ease of installation, making them ideal for modern building projects.

Types of Profiles Produced

1.Metal Studs: Typically C-shaped profiles used as vertical supports in walls. Common sizes include 50mm, 75mm, and 100mm, with thicknesses ranging from 0.3mm to 0.7mm.

2.Metal Tracks: U-shaped profiles used as horizontal supports. Sizes include 51mm, 76mm, and 101mm, with the same thickness range as studs.

3.Furring Channels (Omega Profiles): Used for ceiling applications, these profiles provide support and structure.

4.Wall Angles (Corner Beads): V-shaped profiles used for finishing edges in drywall applications.

5.Main Channels (Carrying Channels): Smaller U-section profiles used for ceiling applications.

Key Features

1.High Precision: Ensures consistent dimensions and high-quality profiles.

2.Versatility: Capable of producing various profiles and sizes to meet different construction requirements.

3.Efficiency: High production speeds, typically ranging from 30m/min to 50m/min.

4.Durability: Robust construction with high-quality materials, such as 45# steel for rollers and Cr12Mov for cutting blades.

5.Automation: Equipped with PLC control systems and touch screens for easy operation and monitoring.

Applications

1.Residential Construction: Used for framing walls and ceilings in homes.

2.Commercial Buildings: Ideal for office spaces, retail stores, and other commercial structures.

3.Industrial Projects: Suitable for warehouses, factories, and other large-scale buildings.

After-Sales Service

1.Warranty: Typically 12 to 24 months, with lifetime technical support.

2.Installation and Training: Some manufacturers offer on-site installation and training services.

3.Maintenance: Free maintenance for a specified period, with options for extended support.

Manufacturers

MIZHI: A leading manufacturer with over 20 years of experience, known for high-quality and durable machines.

MIZHI: Offers a wide range of customizable roll forming machines.

MIZHI: Known for high-speed, stable performance, and one-time molding capabilities.

Conclusion

A Light Steel Keel Roll Forming Machine is an essential tool for modern construction, providing high precision, efficiency, and versatility. It is suitable for producing a variety of light steel profiles for walls, ceilings, and floors. When selecting a machine, consider factors such as production speed, material compatibility, and after-sales service. Reputable manufacturers like Tianjin Haixing and Co-effort Machinery offer reliable solutions with excellent customer support.

Technical Specifications

Parameter | Specification |

Material Thickness | 0.3mm to 1.2mm (galvanized steel, aluminum zinc-coated steel) |

Production Speed | 30m/min to 50m/min |

Roller Material | 45# steel with Cr12Mov cutting blades (HRC 58-62) |

Power Consumption | 5.5KW to 20KW |

Voltage | 380V, 50Hz, 3-phase (customizable) |

Length Tolerance | ±1mm to ±2mm |