Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

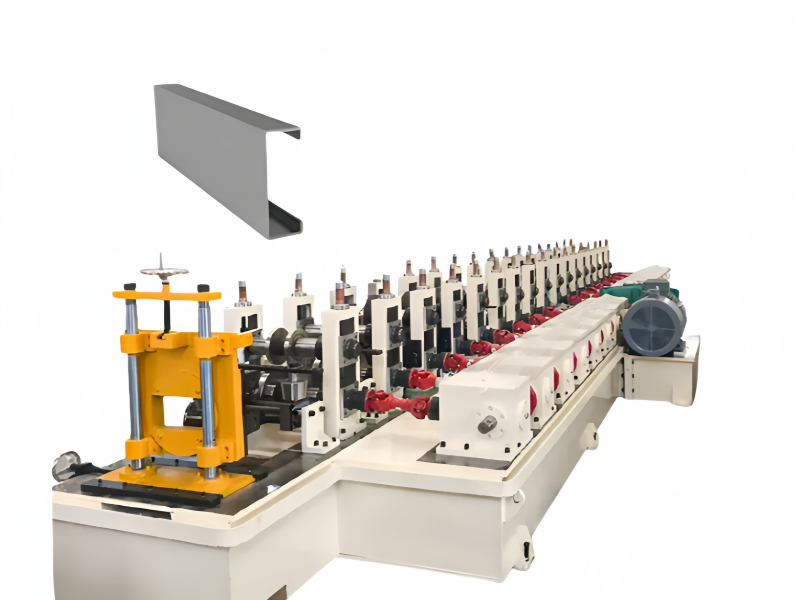

1.Name:Photovoltaic Profile Roll Forming Machine

2.Application: Making Photovoltaic Profile

3.It can custom-design

A Photovoltaic (PV) Profile Roll Forming Machine is a specialized industrial device used to manufacture high-quality support structures for solar panels. These machines are designed to produce various profiles, such as C-shapes, Z-shapes, and channels, which are essential for mounting and supporting solar panels in different installation scenarios.

Below is a comprehensive overview of the machine, its specifications, and key features:

Key Features and Capabilities

1.Material Flexibility:

Suitable for a wide range of materials, including cold-rolled steel, hot-rolled steel, galvanized steel, and aluminum.

Material thickness ranges from 1.0mm to 4.0mm.

2.Custom Profile Creation:

The machine can produce custom profiles and shapes to meet specific installation requirements.

Common profiles include C-shaped, Z-shaped, and channel profiles.

3.High-Speed Production:

Production speeds can reach up to 30 meters per minute, ensuring efficient output.

4.Precision Engineering:

Precision-guided rollers and tooling ensure accurate shaping and forming of metal coils.

The machine features hydraulic tracking punching and cutoff solutions, allowing for continuous operation without stopping for punching and cutting.

5.Automation and Integration:

Many machines come with advanced automation capabilities, including PLC control systems and servo feeders.

Integration with CAD/CAM software streamlines the production process.

Machine Components

1. Decoiler: Available in manual or hydraulic options, with capacities up to 5 tons.

2. Feeding Table: Ensures smooth material feeding into the machine.

3. Leveling Device: Prepares the material by flattening and straightening it.

4. Punching Device: Equipped with hydraulic or servo-driven systems for precise hole punching.

5. Roll Forming System: Consists of multiple roller stations (typically 20-26 stations) for shaping the profiles.

6. Cutting Device: Hydraulic or servo-driven cutting units for precise length cutting.

7. Output System: Options include manual supporters or automatic stackers.

Technical Specifications

1. Power Supply: 220V/380V/415V/460V, 50/60Hz, 3-phase.

2. Machine Weight: Approximately 12 tons.

3. Dimensions: Typically around 25m (L) x 3m (W) x 2m (H).

4. Profile Specifications:

C Purlin: Web 50-250mm, Flange 40-100mm, Lip 10-20mm.

U Purlin: Web 50-250mm, Flange 40-100mm.

Benefits

1. Enhanced Efficiency and Productivity: Continuous operation and automated processes reduce downtime and increase output.

2. High-Quality Output: Precision engineering ensures consistent and high-quality profiles.

3. User-Friendly Operation: Intuitive control units and automated features make the machine easy to operate.

Applications

1. Solar Panel Mounting: Provides structural support for photovoltaic panels in various installation scenarios, including ground-mounted and rooftop systems.

2. Energy Infrastructure: Used in wind turbine support structures and cable management.

3. Lightweight Structural Loads: Suitable for bracing light frames and supporting smaller loads.