Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

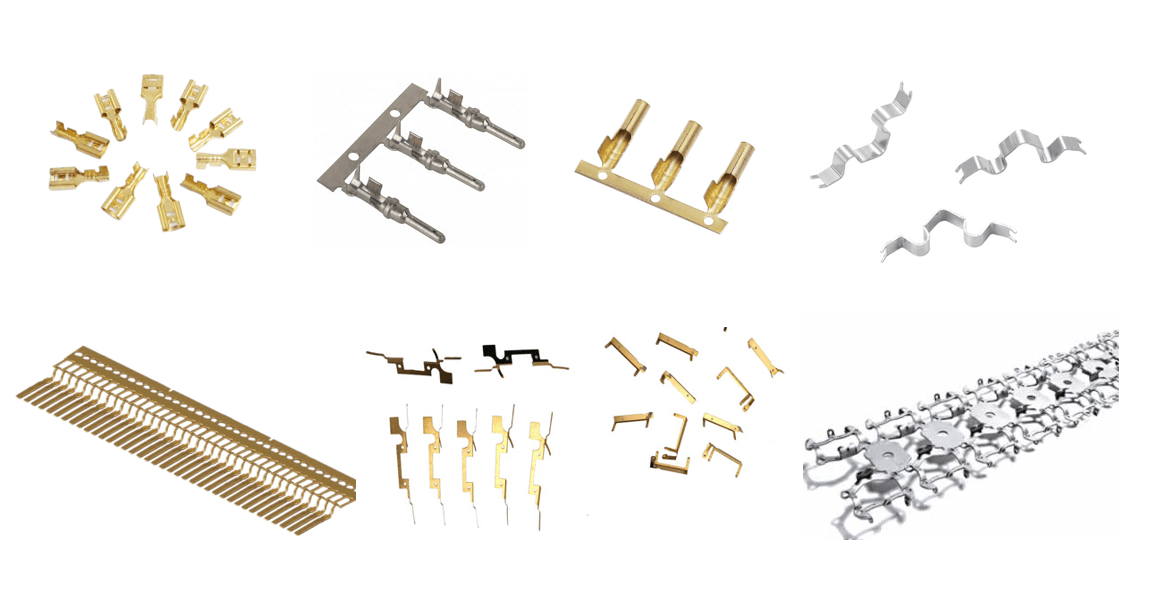

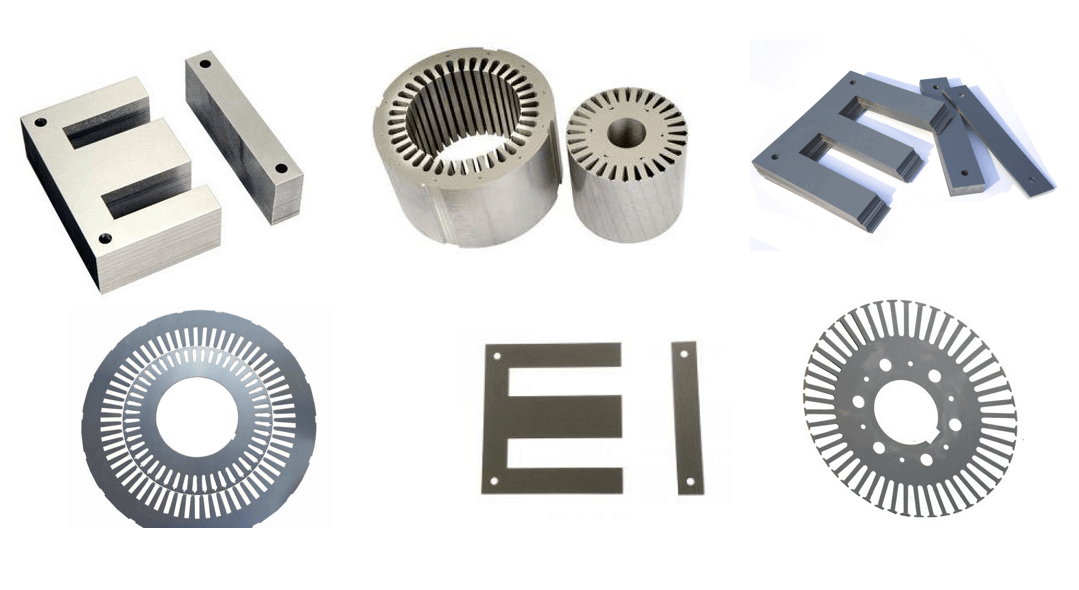

1.Material Thickness: 0.1-2.0 mm

2.Coil Width: 20-400mm

3.Speed: 200-900SPM

4.Material Type: Stainless Steel, Copper, Aluminum, Silicion Steel etc.

5.Suitable for Motor and EI lamination stamping line and terminal stamping line

H frame High speed press machine use integrated special cast iron alloys with high rigidity and shock resistance. The slider is designed with a long guide and equipped with a slider balancing device to ensure precise and stable operation. All anti-wear components are electronically timed automatic lubrication systems, such as the lack of lubricant, the punch will be fully automatic stop. Advanced and simple control system ensures the accuracy of the running and stopping of the slider. It can be used with any automated production requirements to increase production efficiency and reduce costs.

High-speed press stroke (speed) per minute is very high, so its higher requirements on the lubrication system, only the use of forced lubrication system, and high-speed presses with abnormal lubrication detection function can effectively reduce the probability of failure of the press due to lubrication.

Material Type: Stainless Steel, Copper, Aluminum, Silicion Steel etc.

Material Thickness: 0.1-2.0 mm

Coil Width: 20-400mm

Speed: 200-900SPM

Suitable for Motor and EI lamination stamping line and terminal stamping line

H Frame High Speed Press Machine with Spheroidal graphite casting structure with high rigidity, four pieces of guide pillars and alloy copper sleeve design.

H Frame Press machine is suitable for various fields, eyelet, metal button, motor, connector, computer, mobile phone,LED, car, nonstandard metal parts and so on.

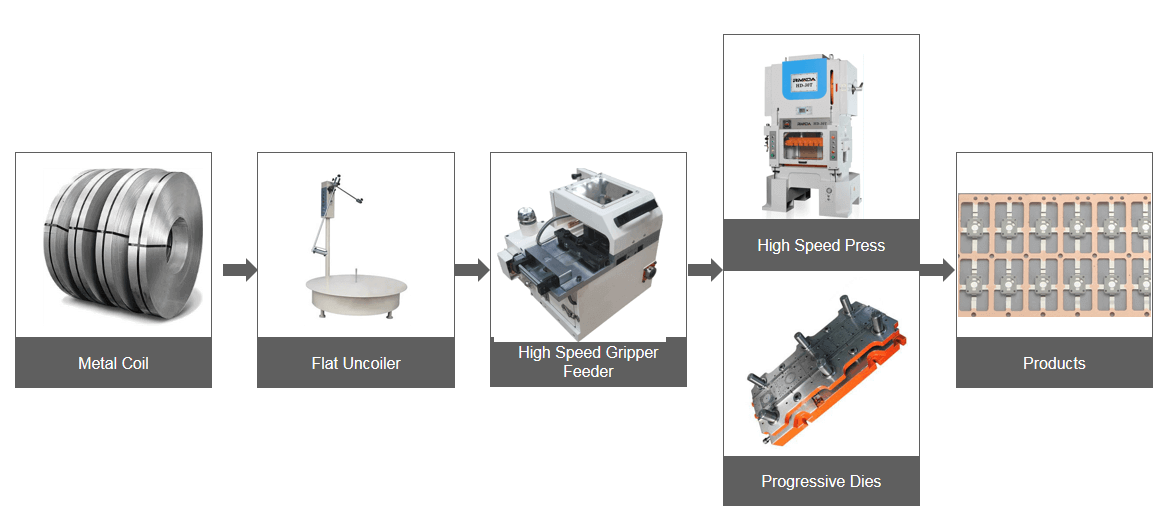

The configuration of High speed press line for making LED parts.

Step-1: Flat Decoiler Machine, Loading coil and uncoilling coil.

Step-2: High speed feeder machine, Feed coil to press machine.

Step-3: High speed press machine with the moulds,pressing to the end product

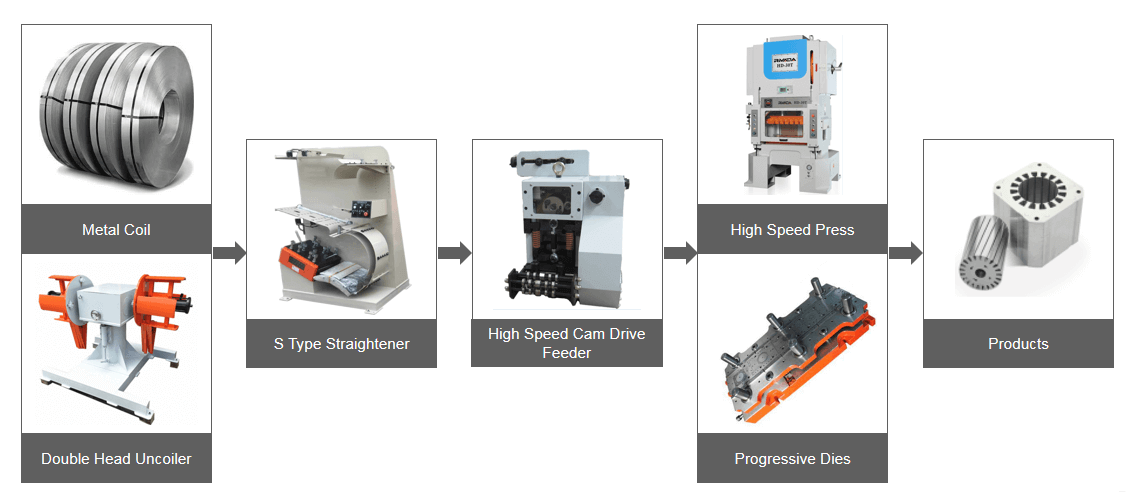

The configuration of high speed press line for Motor and EI lamination

Step-1: Double Head Decoiler machine, Loading coil and uncoilling coil.

Step-2: High speed S Loop Straightener machine, leveling the strips.

Step-3: High speed Cam Feeder machine, Feed coil to press machine.

Step-4: High speed press machine with the moulds,pressing to the end product

Model | RH-30 | RH-45 | RH-65 | RH-85 | ||||||||

Capacity | 30Ton | 45Ton | 65Ton | 85Ton | ||||||||

Stroke of slide | 25mm | 30mm | 40mm | 25mm | 30mm | 40mm | 30mm | 40mm | 50mm | 30mm | 40mm | 50mm |

Speed(SPM) | 200-900 | 200-800 | 200-600 | 200-900 | 200-800 | 200-600 | 200-600 | 200-500 | 200-400 | 200-700 | 200-600 | 200-500 |

Die-height(mm) | 192-232 | 190-230 | 185-225 | 208-248 | 205-245 | 200-240 | 270-320 | 265-315 | 260-310 | 370-320 | 365-315 | 360-310 |

Bolster(mm) | 660mmx460mmx110mm | 780mmx650mmx120mm | 950mmx700mmx135mm | 1200mmx900mmx150mm | ||||||||

Area of slide(mm) | 630mm x 330mm | 730mmx380mm | 900x450 | 1100x650 | ||||||||

Slide adjustment(mm) | 40mm | 40mm | 50mm | 50mm | ||||||||

Bed opening(mm) | 100x 500 | 120x550 | 125x650 | 850x150 | ||||||||

Motor(HP) | 10 | 15 | 25 | 30 | ||||||||

Machine weight(kg) | 5200kg | 8516kg | 16080kg | 19000kg | ||||||||

Lubrication system | Forceful Automation & oil cooler | |||||||||||

Variable speed system | Inverter | |||||||||||

Clutch and Brake | Air clutch,Friction brake | |||||||||||

Vibration reduction | Mechanical Mounting or Pneumatic Mounting | |||||||||||