Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

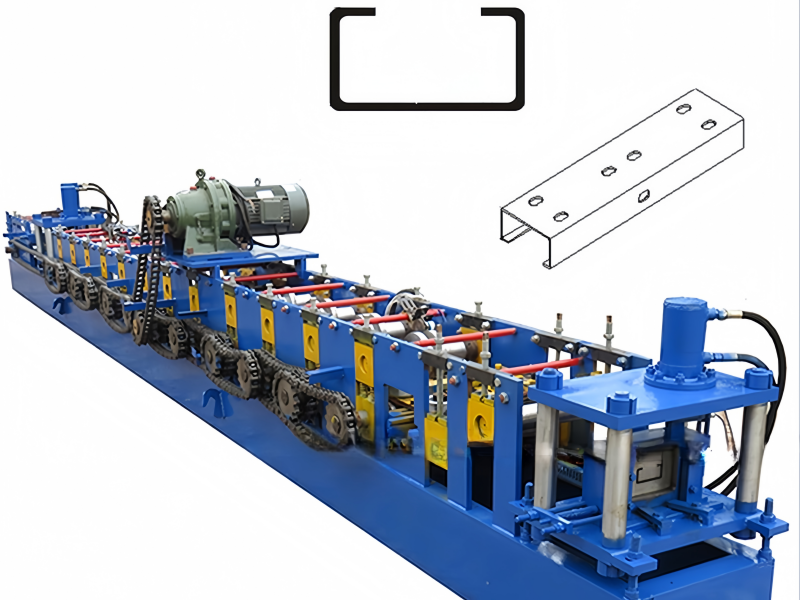

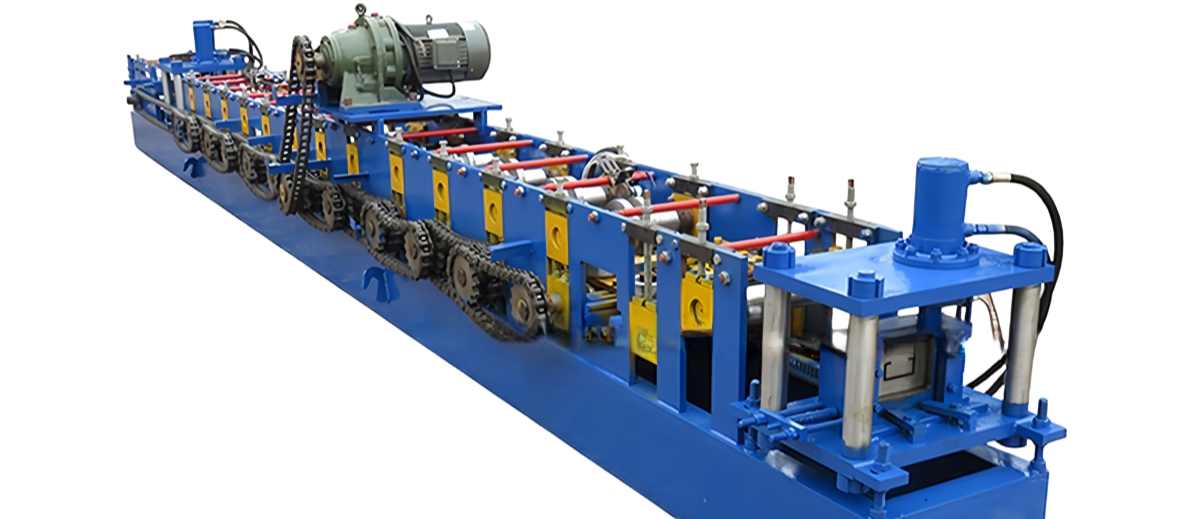

1.Name:Purlin Roll Forming Machine

2.Application: Making Purlin

3.It can custom-design

The Purlin Roll Forming Machine is a specialized piece of industrial equipment designed to produce high-quality purlins, which are structural beams used in metal buildings and roofing systems.

The Purlin Roll Forming Machine is a specialized piece of industrial equipment designed to produce high-quality purlins, which are structural beams used in metal buildings and roofing systems.

Below is a detailed description of this machine:

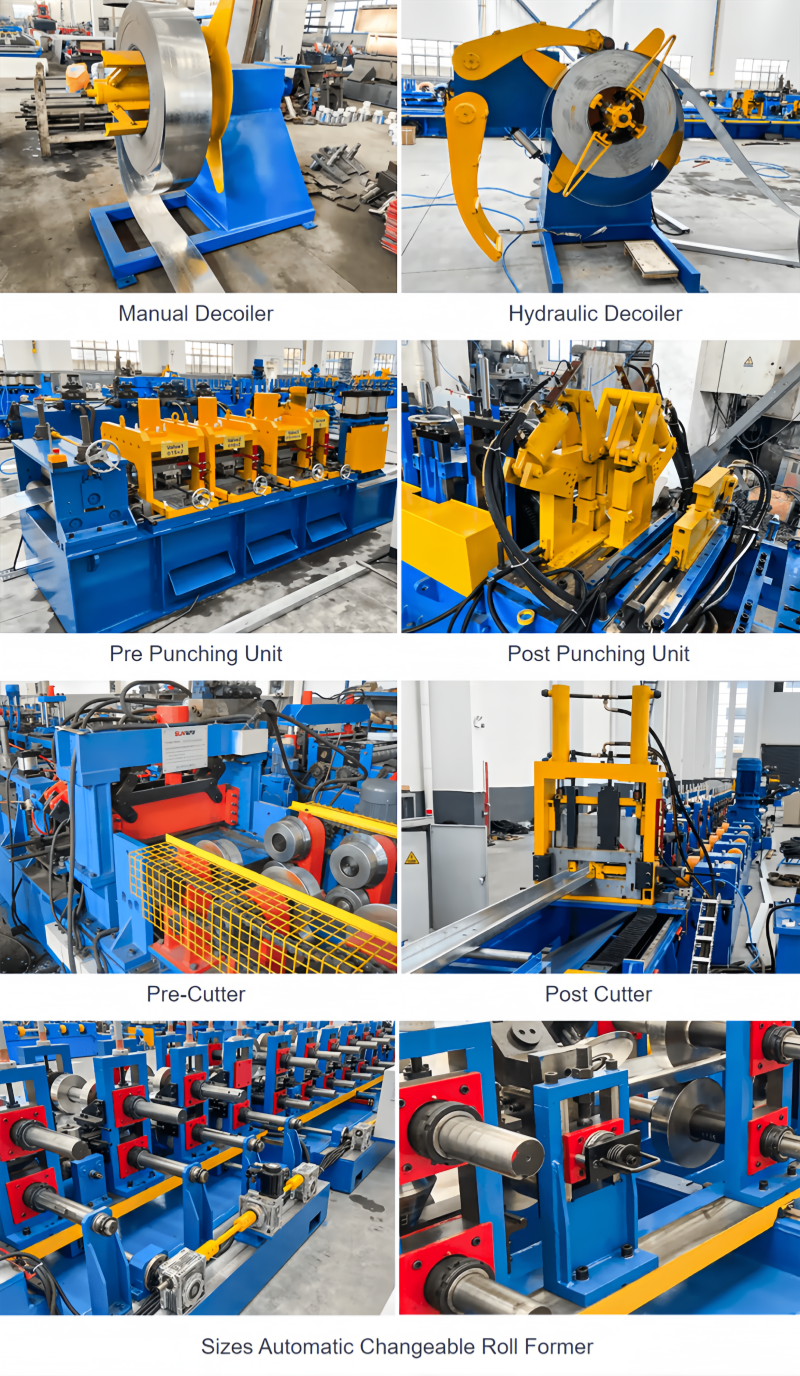

Main Components

1.Decoiler: This component holds the metal coil and feeds it into the roll forming machine. It can be manual or automatic and is designed to handle different widths and thicknesses of metal.

2.Leveling Unit: This unit flattens and straightens the metal strip or sheet before it enters the roll former, ensuring even feeding and improving the accuracy and consistency of the final product.

3.Punch Press: This component punches holes or shapes into the metal strip as it enters the roll former. It allows for customized hole patterns, which are important for attaching purlins to other building components.

4.Roll Former: This is the core of the machine, consisting of a series of rollers that gradually shape the metal strip into the desired purlin shape. The rollers can be adjusted to create different shapes and sizes of purlins.

5.Cutting System: This component cuts the finished purlin to the desired length. It can use hydraulic shearing or sawing methods.

6.Control Panel: This allows operators to control and monitor the machine. It includes digital readouts, control knobs, and emergency stop buttons.

Applications

Purlin roll forming machines are widely used in the construction industry to produce structural beams for metal buildings, roofing systems, and other applications where high strength and durability are required.

Working Process

1.Decoiling: The metal coil is loaded onto the decoiler and fed into the machine.

2.Leveling: The metal strip is flattened and straightened by the leveling unit.

3.Punching: Holes or shapes are punched into the metal strip by the punch press.

4.Roll Forming: The strip passes through the roll forming stations, where it is gradually shaped into the desired purlin profile.

5.Cutting: The formed purlin is cut to the specified length by the cutting system.

6.Output: The finished purlins are stacked or conveyed for further handling.

Types of Purlin Roll Forming Machines

1.Standard Lines: Pre-engineered models with fixed speed and output, suitable for regular purlins in standard sizes.

2.Customized Lines: Custom-built to meet specific size and feature requirements, with highly configurable parameters and advanced automation.

Technical Specifications

1.Material Compatibility: Works with galvanized steel, stainless steel, and aluminum.

2.Forming Speed: Typically ranges from 10 to 25 meters per minute.

3.Output Capacity: Can produce up to 18,000 pieces per shift.

4.Material Thickness: Suitable for materials ranging from 0.5 to 3.2 mm.

5.Control System: Uses PLC, HMI touchscreen, sensors, and servo drives for automation and monitoring.

Advantages

1.High Precision: The machine can produce purlins with high accuracy and consistency.

2.Customization: It can be configured to produce purlins of various shapes and sizes.

3.Efficiency: Automated controls and high-speed operation increase production efficiency.

4.Versatility: Suitable for different types of metal and applications.