Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

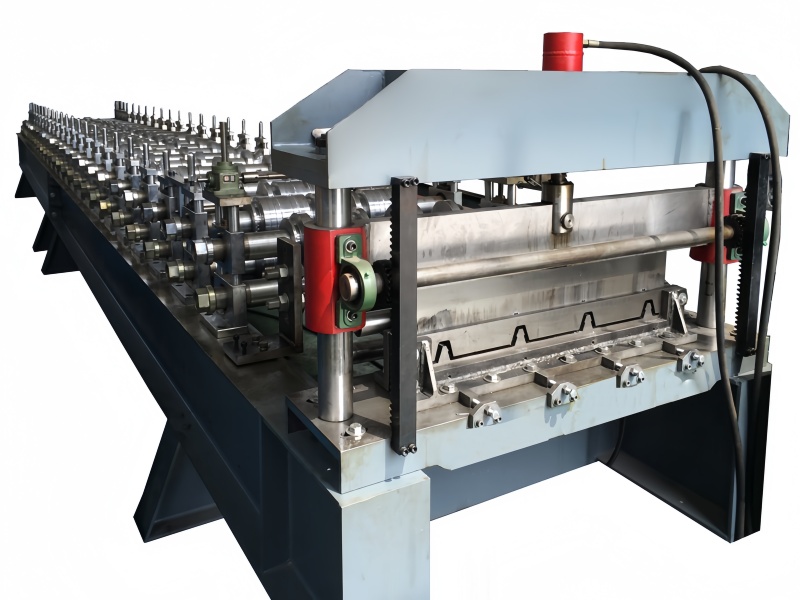

1.Name:Rollf/Wall Sheet Roll Forming Machine

2.Application: Making Rollf/Wall Sheet

3.It can custom-design

The Rollf/Wall Sheet Roll Forming Machine is a highly efficient and versatile piece of industrial equipment designed to produce high-quality wall sheets for various construction projects. Below is a detailed description of this machine:

Main Components

1.Decoiler: This part is responsible for unwinding the metal coil smoothly and feeding it into the machine. It usually comes with a coil loading mandrel or reel, and a coil straightener to correct coil curvature.

2.Feeding Device: It ensures the metal sheet is accurately guided into the roll forming section. It often includes an adjustable entry/feeding guide to accommodate materials of different widths.

3.Roll Forming Stations: This is the core section of the machine where the metal is gradually shaped into the desired profile through a series of progressively shaped rollers. Each set of rollers bends the metal slightly until the final shape is achieved.

4.Cutting Device: Once the metal has been formed into the correct profile, it is cut to the desired length by a cutting unit. The cutting device can be hydraulic or motor-driven.

5.Electric Control System: Modern roll forming machines are typically equipped with advanced PLC control systems and touchscreen interfaces for easy operation and monitoring. Some machines also offer remote control options.

Working Process

1.The metal coil is loaded onto the decoiler and fed into the machine.

2.As the coil travels through the machine, it undergoes a series of bending, cutting, and shaping operations in the roll forming stations.

3.The formed metal sheet is then cut to the desired length by the cutting device.

4.The finished wall sheets are either stacked on a table or ejected onto a conveyor for further handling.

Features and Advantages

1.High Precision: The rollers are usually made from high-grade steel or chrome-plated to ensure durability and precision.

2.Efficiency: The machine can produce panels with consistent quality and precision at a high speed. The continuous production and high-speed operation significantly boost productivity.

3.Customization: It can be easily adjusted to produce different profiles and sizes of wall cladding panels. The machine can handle a variety of materials, including PPGI, galvanized steel, and aluminum sheet.

4.Cost-Effectiveness: It lowers labor costs and minimizes material waste, making the process economical.

5.Durability: The produced panels are strong and weather-resistant, ideal for long-lasting applications.

6.User-Friendly: The advanced control systems and low maintenance requirements enhance ease of operation.

Specifications

1.Suitable Material: PPGI, galvanized steel, aluminum sheet.

2.Material Width: Typically 1250mm or customizable.

3.Material Thickness: 0.3-0.8mm or customizable.

4.Forming Speed: 20/30/40/50/60 m/min or customizable.

5.Roller Material: No.45 steel with Chromeplate.

6.Power Source: 380V/3PH/50HZ or customizable.

7.Machine Weight: Around 3.5T to 20T depending on the model.

8.Machine Dimensions: Vary depending on the model, typically around 7000mm*1500mm.

Applications

The Rollf/Wall Sheet Roll Forming Machine is widely used in the construction industry to produce wall cladding panels for various types of buildings. It can also be used to manufacture other metal components such as studs, tracks, and other structural elements for walls and ceilings.