Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Name:Shelf/Storage Rack Profile Roll Forming Machine

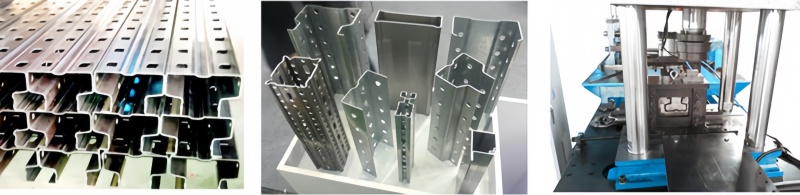

2.Application: Making Shelf/Storage Rack Profile

3.It can custom-design

Introduction

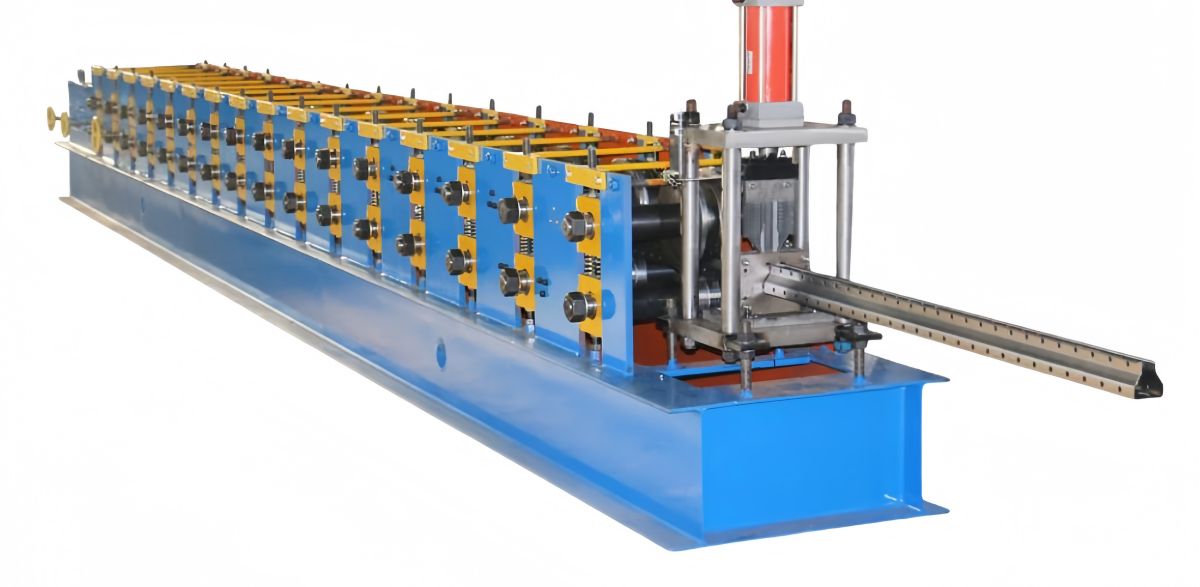

A Shelf/Storage Rack Profile Roll Forming Machine is a specialized piece of equipment designed to produce steel profiles for storage racks and shelving systems. It is widely used in the manufacturing of warehouse racking, supermarket shelves, and heavy-duty storage solutions. This machine offers efficient, high-volume production with precise tolerances and low operational costs.

Main Components

1.Decoiler: Unwinds the steel coil to feed the material into the machine.

2.Feeding Device: Guides the metal strip through the machine with precision.

3.Leveling System: Ensures the metal strip is flat before forming.

4.Roll Forming Stations: Gradually shape the metal strip into the desired profile through a series of rollers.

5.Punching/Notching Device: Creates holes or notches in the profile for assembly.

6.Cutting Device: Cuts the formed profile to the specified length.

7.PLC Control System: Manages the entire production process, allowing for automation and precision.

Working Principle

The machine operates by feeding a steel coil through a series of rollers that progressively shape the material into the desired profile. The process includes:

1.Decoiling: The steel coil is unwound and fed into the machine.

2.Leveling: The metal strip is flattened to ensure uniformity.

3.Roll Forming: The strip is shaped into the desired profile through multiple rolling stations.

4.Punching/Notching: Holes or notches are created as required.

5.Cutting: The formed profile is cut to the specified length using computer-controlled saws.

6.Output: The finished profiles are collected on an output table.

Technical Specifications

Parameter | Specification |

Material Thickness | 0.5 mm to 2 mm cold-rolled steel |

Material Width | Up to 1200 mm |

Production Speed | Up to 30 m/min |

Cutting Accuracy | ±1.0 mm |

Main Motor Power | 18.5 kW |

Hydraulic Station Power | 4 kW |

Roller Material | GCr15 with heat treatment (HRC58-62°) |

Control System | PLC with touch screen interface |

Applications

1.Warehouse Racking: Produces vertical uprights and horizontal beams for storage racks.

2.Supermarket Shelves: Manufactures shelving systems for retail environments.

3.Heavy-Duty Storage Solutions: Creates robust storage systems for industrial use.

Advantages

1.High Efficiency: Continuous production process increases output.

2.Precision: Automated control system ensures consistent quality and dimensional accuracy.

3.Flexibility: Can produce a variety of profiles and sizes.

4.Cost-Effective: Reduces material waste and operational costs.

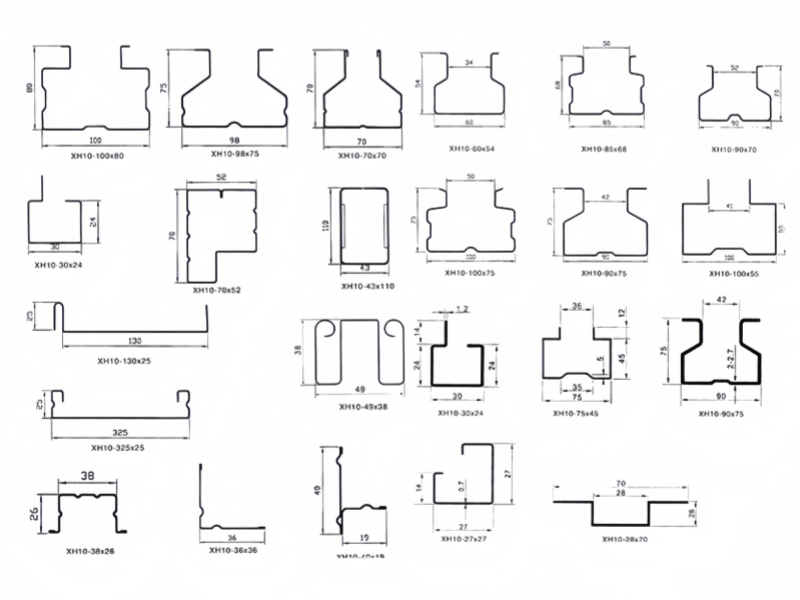

Customization Options

1.Profile Design: Custom profiles can be engineered to meet specific requirements.

2.Automated Features: Options include automatic decoiling, inline punching, and automatic stacking.

3.Surface Treatments: Options for galvanizing, painting, or other finishes.

This comprehensive guide provides an overview of the Shelf/Storage Rack Profile Roll Forming Machine, its components, working principle, technical specifications, applications, and advantages. For more detailed information or customization options, it is recommended to consult with a professional equipment manufacturer.