Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Model No.: HS

2.Applications: Pressing Line/Metal Stamping Line

3.Applicable Coil Width: 600mm

4.Applicable Coil Thickness: 0.5-4.5mm/1.0-6.0mm

5.Speed: 15m/min

6.Suitable for vary kind of coil material, such as Galvanized steel, Stainless steel, CR Steel, HR Steel, Galvanized steel, Stainless steel,Aluminum, Cooper etc.

Metal sheet straightener machines is used to straighten an uneven metal sheet, and the extrusion effect of a certain thickness of the strip or plate is achieved through the upper and lower rollers, so as to achieve a smooth effect. It is also called a leveler. The general leveler is mainly three or four. And before and after the transfer roller. The upper part has a handle for fine adjustment of the leveling thickness accuracy.

Model No.: HS

Applications: Pressing Line/Metal Stamping Line

Applicable Coil Width: 600mm

Applicable Coil Thickness: 0.5-4.5mm/1.0-6.0mm

Speed: 15m/min

Suitable for vary kind of coil material, such as Galvanized steel, Stainless steel, CR Steel, HR Steel, Galvanized steel, Stainless steel,Aluminum, Cooper etc.

Worm gears guarantee a high precision straightening value adjustment.

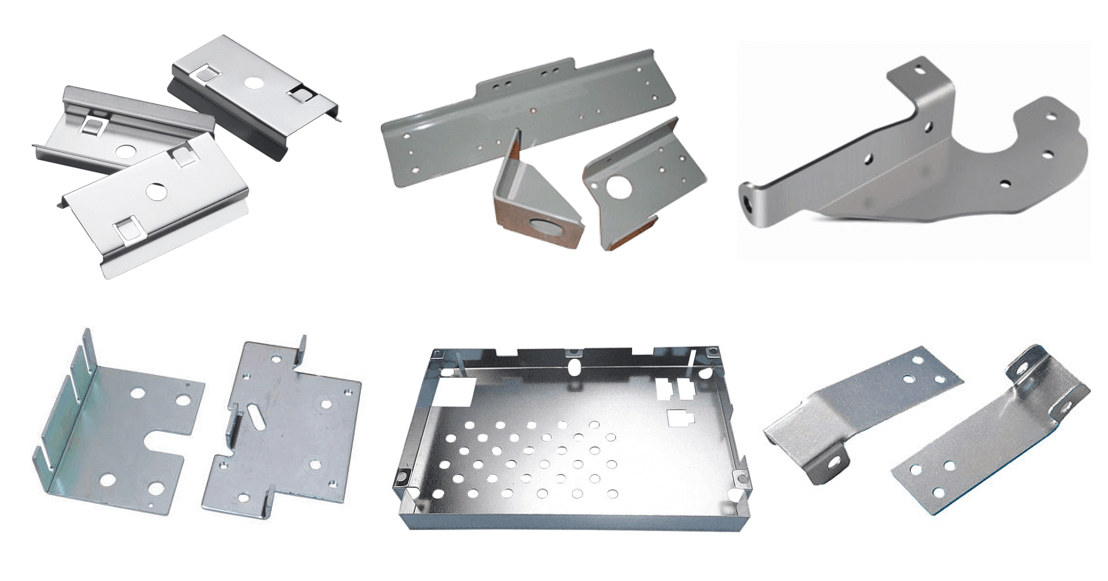

Metal sheet straightener machine is suitable for all kinds of metal sheet stamping, such as the hardware parts, home appliances, furniture hardware, motorcycle accessories, mobile phone accessories, computer accessories and so on.

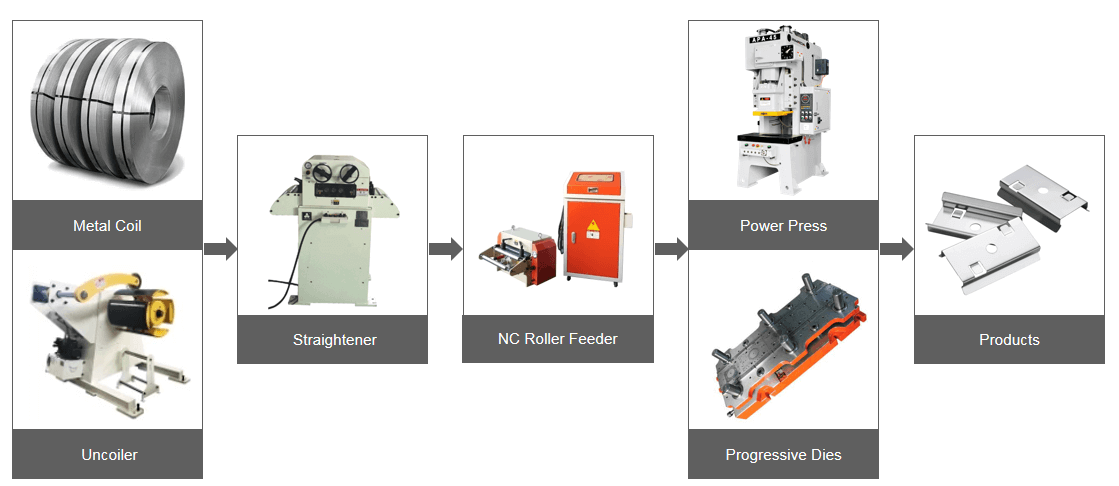

The configuration of metal sheet stamping line.

Step-1: Uncoiler machine, Loading coil and uncoilling coils

Step-2: Metal straightener machine, leveling the strips and lead it to feeder machine.

Step-3: Nc Servo Feeder machine, Feed coil to press machine.

Step-3: Power press machine with the moulds,pressing to the end product.

Model | HS-300A | HS-400A | HS-500A | HS-600A | HS-300B | HS-400B | HS-500B | HS-600B |

Coil Width | 300mm | 400mm | 500mm | 600mm | 300mm | 400mm | 500mm | 600mm |

Thickness | 0.5-4.5mm | 1.0-6.0mm | ||||||

Straightener Roll | Ø70mm * 9pcs | Ø90mm * 9pcs | ||||||

Pinch Roll | Ø95mm * 2pcs | Ø120mm * 2pcs | ||||||

Pressure | Cylinder Roller Pressing Way | |||||||

Adjustment | Eccentric turbine worm roller adjusting | |||||||

Power | 5 HP | 7.5 HP | 5 HP | 7.5 HP | ||||

Speed | 15m/min | |||||||