Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

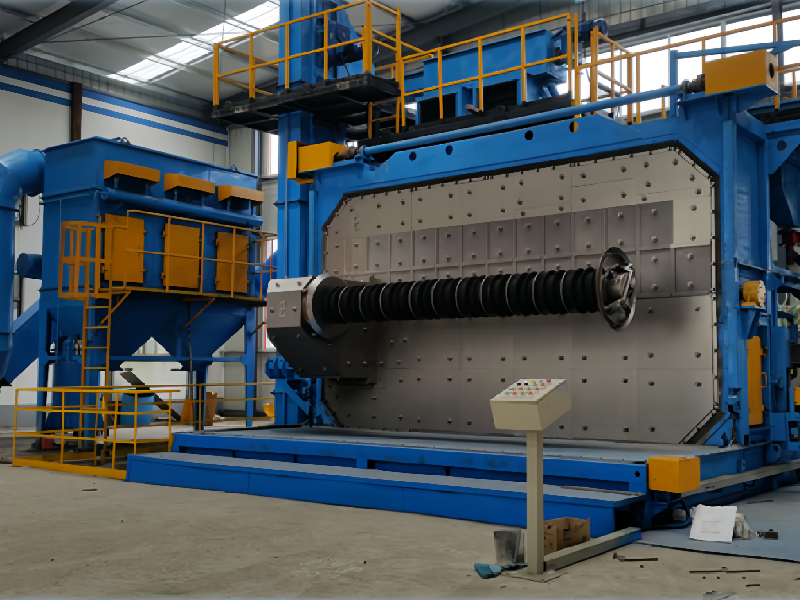

1.Model: MZ-5300

2.Wire Transport Way : Double Shafts

3.Shafts Length:5300mm

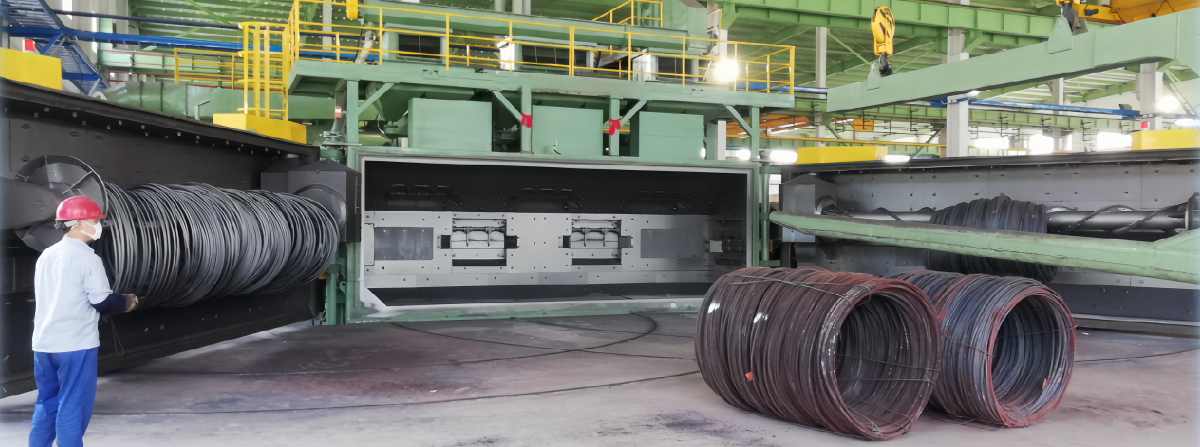

Introduction to Double Shaft Wire Rod Shot Blasting Machine

The Double Shaft Wire Rod Shot Blasting Machine is an advanced industrial equipment designed to efficiently clean, descale, and improve the surface quality of wire rods. It utilizes high-velocity steel shots or other abrasive media propelled by dual blast turbines to remove rust, mill scale, and other surface contaminants. This machine is particularly effective in preparing wire rods for downstream processes such as coating, drawing, and welding.

Applications

This machine is widely used across various industries, including:

1.Automotive Industry: For cleaning and preparing wire rods used in springs, stabilizer bars, and fasteners. It enhances fatigue resistance and coating adhesion, crucial for automotive components.

2.Construction Industry: Used for treating reinforcement materials like steel wires and rebars to ensure strong bonding with concrete.

3.Aerospace Sector: For precise surface preparation of high-strength steel cables and landing gear springs, meeting strict industry standards.

General Manufacturing: For wire drawing processes, reducing tool wear and ensuring consistent product quality.

Advantages

1.High Cleaning Efficiency: The dual blast turbines ensure thorough and uniform surface treatment, removing contaminants effectively.

2.Improved Fatigue Resistance: Shot blasting induces compressive stresses on the wire rod surface, enhancing its mechanical properties and durability.

3.Consistent Quality: Achieves uniform surface finish, essential for downstream processes like coating and drawing.

4.Environmental Friendliness: Equipped with a dust collection system and recyclable media, minimizing environmental impact.

5.Reduced Maintenance Costs: The machine is designed with wear-resistant components and easy-to-replace parts, reducing maintenance workload.

6.Increased Productivity: Automated operation and high processing speed ensure efficient production, suitable for high-volume manufacturing.

Content and Structure

The Double Shaft Wire Rod Shot Blasting Machine typically consists of the following components:

1.Blast Chamber: Where the shot blasting process takes place.

2.Dual Blast Turbines: Propel abrasive media at high speed to clean the wire rods.

3.Wire Rod Conveyor System: Ensures continuous and uniform exposure of the wire rods to the blasting process.

4.Abrasive Recovery System: Collects and recycles the abrasive media for reuse, reducing waste.

5.Dust Collection System: Captures dust and debris, maintaining a clean working environment.

6.Control Panel: For easy operation and monitoring of the machine.

Working Process

1.Loading: Wire rods are loaded into the machine via an automated conveyor system.

2.High-Speed Abrasive Cleaning: Dual blast turbines propel steel shots or other abrasives at high velocity onto the wire rod surface, removing rust, scale, and contaminants.

3.Full-Surface Coverage: The wire rods are rotated or moved continuously to ensure all surfaces are evenly treated.

4.Dust Extraction and Abrasive Recycling: The dust collection system removes debris, while the abrasive recycling system reclaims and reuses the media.

5.Inspection and Output: The cleaned wire rods are inspected to ensure they meet surface quality requirements before being sent for further processing.

How to Choose?

When selecting a Double Shaft Wire Rod Shot Blasting Machine, consider the following factors:

1.Material Requirements: Ensure the machine can handle the specific wire rod materials and diameters.

2.Production Volume: Choose a machine with the appropriate capacity for your production needs.

3.Automation Level: Opt for a machine with high automation to reduce labor costs and increase efficiency.

4.Environmental Impact: Select a machine with an efficient dust collection and media recycling system to minimize environmental impact.

5.Cost: Evaluate both the initial investment and ongoing operational costs.

Conclusion

The Double Shaft Wire Rod Shot Blasting Machine is a highly efficient solution for cleaning and preparing wire rods, offering significant advantages in terms of surface quality, productivity, and environmental friendliness. It is a valuable investment for industries requiring high-quality wire rod surface treatment, ensuring improved product durability and reduced operational costs.