Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

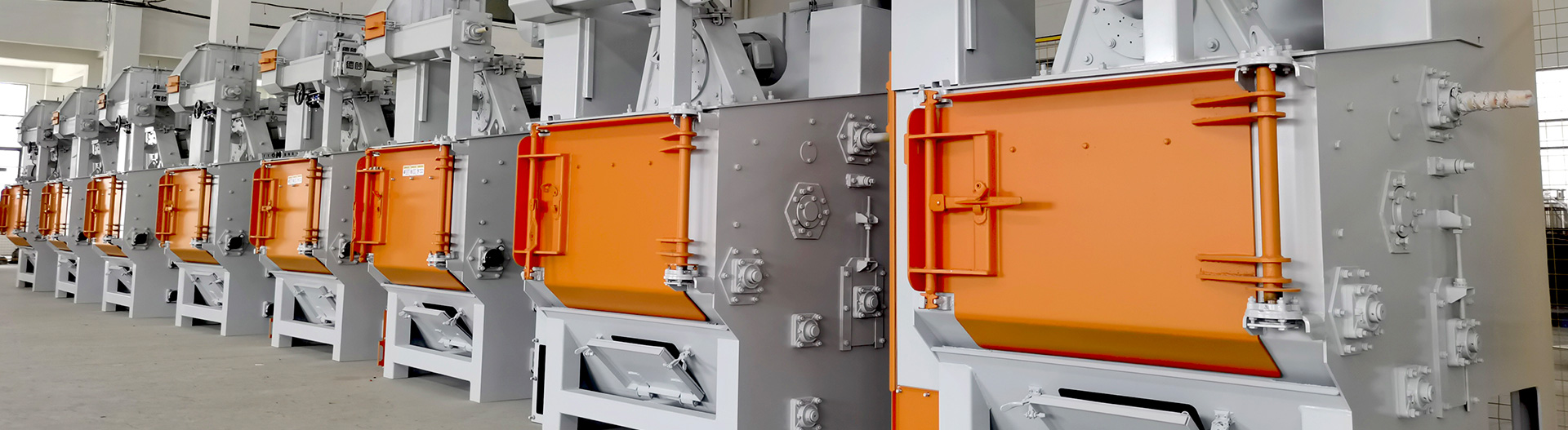

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

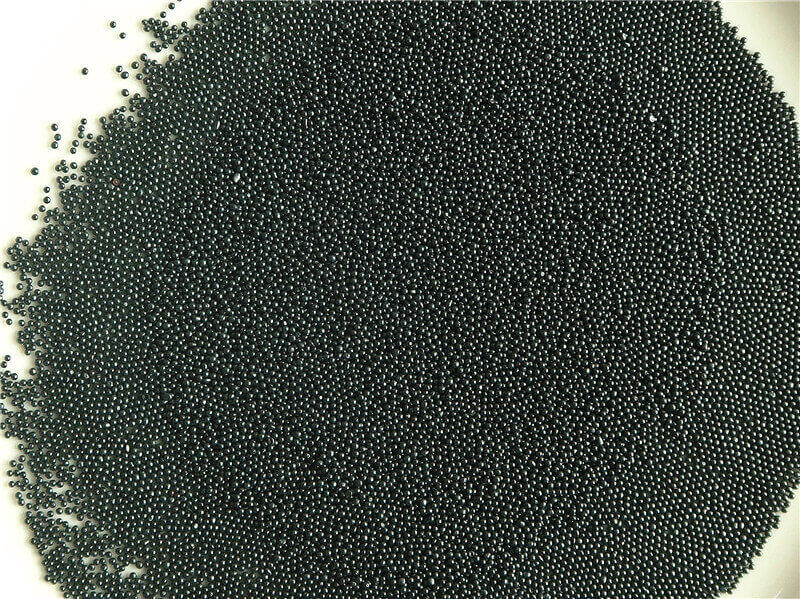

Steel abrasives are steel particles that are used as abrasive or peening media.They are usually available in two different shapes (shot and grit) that address different industrial applications.

Steel shot refers to spherical grains made of molten steel through an atomization ("granulation") process, available in different sizes and hardnesses.

Steel abrasives are steel particles that are used as abrasive or peening media.They are usually available in two different shapes (shot and grit) that address different industrial applications.

Steel shot refers to spherical grains made of molten steel through an atomization ("granulation") process, available in different sizes and hardnesses.

The advantages of cast steel shot as fellows:

Adopt medium frequency furnace for smelting to ensure high quality molten steel;

Using refining furnace to refine molten steel;

High speed centrifugal casting;

To separate hollow and defective particles effectively, to improve the density of steel shot;

Adopt secondary quenching treatment;

Using temper treatment,to refine the internal organization;

Using fine screening,to comply with American SAE-J444 standard;

Steel shot and grit address numerous sectors since cleaning, surface preparation or shot peening applications are used by many industries as a part of their construction, renovation or repair processes. The main industrial sectors employing steel abrasives are:

1.Automotive industry

2.Construction

3.Metallurgy

4.Petrochemical industry

Smelting:Using Electric arc furance smelting,steel components can be adjusted to reduce the content of harmful elemental such as sulfur,phosphorus .

Refining:Using refining furnace to refine molten steel,improving the purity of molten steel,then the steel shot can get better material.

Granulation:High speed centrifugal casting forming,effective control the forming quality and reduce physical defects.

Selection:To separate hollow and defective particles effectively, to improve the density of steel shot.

Quenching:Using secondary quenching to refine grains and make the product more compact internal microstructure to enhance the toughness.

Tempering:To refine the internal organization further to reach the requirement of different hardness,to make it's uniformity of the organization and hardness best by precise temperature and time control.

Broken:Unique crushing prcess make the steel grit has better fullness and angularity,to reduce the internal cracks of the steel grit grain as well.

Fine Sieve:To control particle size Precesion,make the products meet the American SAE-J444 standard.

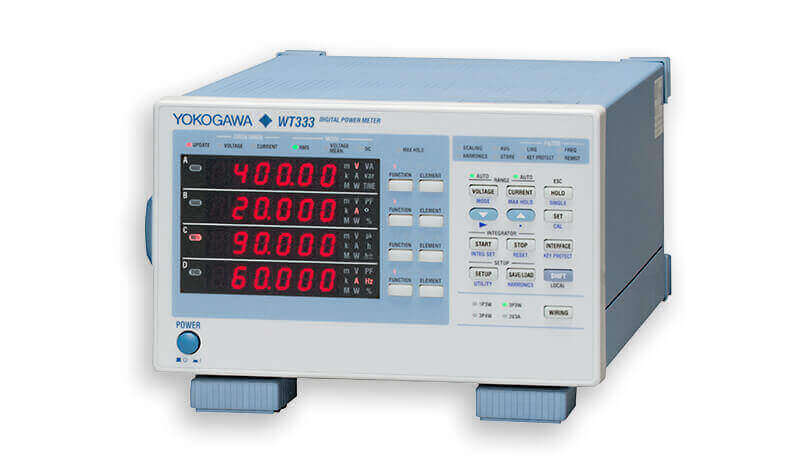

Hardness Tester

1. No friction spindle,High testing accuracy.

2. Stable construction,High testing efficiency.

3. High precision micrometer readings metering system.

4. Testing process automation,no human operator error.

5. Accuracy class:GB/T4340.2/ISO6507-2 and American ASTME92.

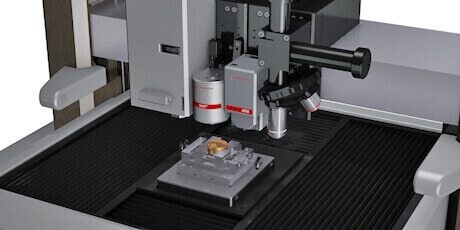

Microscope

1. To identificate and analyze the organizational structure of various metals and alloys.

2. The instrument is widely used in factories or laboratories to identify the quality of castings,inspect raw materials,or Microstructure analysis after-treatment.

Three Element Analyzer

1. A newer multi-element analyzer.

2. It is used in detection of variety of elements such as :Si/Mn/P/Cr/Ni/Mo/Cu/Ti of all kinds of material such as:ball mill cast iron,cast iron,ductile iron,alloy cast iron and stainless steel ,carbon steel,low alloy steel,high alloy steel etc. The analysis result is fast and accurate.

Carbon & Sulfur Analyzer

1. The equipment is one of the high-tech products and a collection of optical ,mechanical and electrical ,computer,analysis technology.

2. It has the advantage of wide measuring range,strong anti-jamming capability,complete functions,simple operation,analysis results accurate and reliable,ti is the ideal analysis equipment of the 2 element of carbon and sulfur in industries determination.

| Model | S50,S70,S110,S130,S170,S230,S280,S330,S390,S460,S550,S660,S780,S930 | |

| Item | Name | Steel Shot |

| Chemical Composition | C | 0.85-1.20 |

| Chemical Composition | Si | 0.40-1.20 |

| Chemical Composition | Mn | 0.60-1.20(S170:0.50-1.20; S110/S70:0.35-1.20 |

| Chemical Composition | S | ≤0.05 |

| Chemical Composition | P | ≤0.05 |

| Hardness | HRC40-50 | |

| Microstructure | Homogeneous tempered martensite or troostite | |

| Density | ≥7.20g/cm³ | |

| External Form | Round hollow particles<10% | |

| SAE J444 Steel Shot | Screen Mesh Size | Inch | |||||||||||

| S930 | S780 | S660 | S550 | S460 | S390 | S330 | S280 | S230 | S170 | S110 | S70 | ||

| All Pass | 6 | 0.1320 | |||||||||||

| All Pass | 7 | 0.1110 | |||||||||||

| ≥90% | All Pass | 8 | 0.0937 | ||||||||||

| ≥97% | ≥85% | All Pass | All Pass | 10 | 0.0787 | ||||||||

| ≥97% | ≥85% | All Pass | 12 | 0.0661 | |||||||||

| ≥97% | ≥85% | All Pass | 14 | 0.0555 | |||||||||

| ≥97% | ≥85% | All Pass | 16 | 0.0469 | |||||||||

| ≥96% | ≥85% | All Pass | 18 | 0.0394 | |||||||||

| ≥96% | ≥85% | All Pass | 20 | 0.0331 | |||||||||

| ≥96% | ≥85% | ≤10% | 25 | 0.028 | |||||||||

| ≥96% | ≥85% | All Pass | 30 | 0.0232 | |||||||||

| ≥97% | ≤10% | 25 | 0.0197 | ||||||||||

| ≥85% | All Pass | 40 | 0.0165 | ||||||||||

| ≥97% | ≤10% | 45 | 0.0138 | ||||||||||

| ≥85% | 50 | 0.0117 | |||||||||||

| ≥90% | ≥85% | 80 | 0.07 | ||||||||||

| ≥90% | 120 | 0.0049 | |||||||||||

| 200 | 0.0029 | ||||||||||||