Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

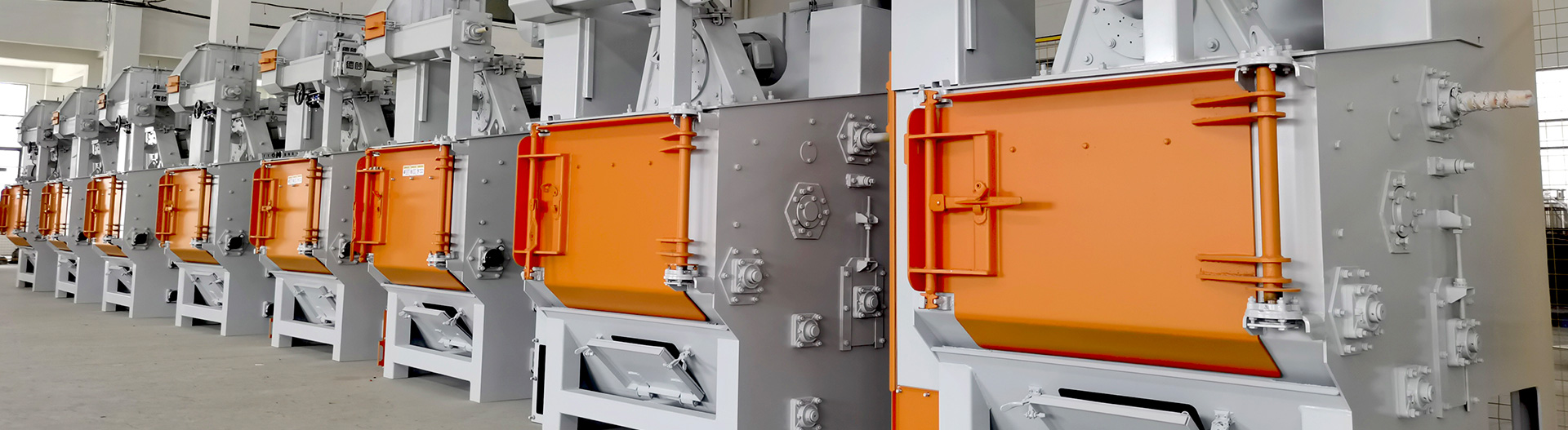

A dust collector is a system used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air or gas. Designed to handle high-volume dust loads, a dust collector system consists of a blower, dust filter, a filter-cleaning system, and a dust receptacle or dust removal system. It is distinguished from air purifiers, which use disposable filters to remove dust.

According to the different ways of dust removal, dust collectors are divided into pulse dust collector, bag dust collector, Venturi wet dust collector, etc. Pulse dust collector is a device that removes the dust attached to the filter medium (cloth bag or filter cartridge) by injecting compressed air. Venturi dust collector is a device that makes the dust-containing gas and liquid (half of which is water) contact closely, and uses the inertial collision of water droplets and particles and other functions to capture particles or increase particles.

Cartridge Filter Dust Collector is a system used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air or gas. Designed to handle high-volume dust loads, a dust collector system consists of a blower, dust filter, a filter-cleaning system, and a dust receptacle or dust removal system. It is distinguished from air purifiers, which use disposable filters to remove dust.

The dust-laden gases enter the collector through through the ductwork. Fans either push or pull the air through the ducts. Air travels down to the hopper and hits a set of baffles and makes a turn and goes back up. This creates an area for air to slow down and allows majority of dust to fall to hopper without reaching the cartridges. Next, the air passes through the dust collector’s cartridge filters. which is the metal sheet separating the dirty and clean air spaces.The filters capture the dust. Some of it falls off. Some of it sticks to the filters. Gaskets at the top of each filter seal it to the tube sheet to keep dust from sneaking through. A pulse of compressed air blows into the filters. Because the pulse of compressed air goes in the reverse direction of the regular airflow, we call it a reverse pulse-jet collector. The pulse of compressed air blows the accumulated dust off the filters. The dust drops out of the collector and the filters are ready to collect more dust. On the other side of the filters, filtered air enters the clean air plenum. From there, clean air comes up through center of cartridges and out the collector exhaust. Air is now clean and safe for the environment.

Widely Application;

Adopt high quality filter element, more environmental protection.

Cyclone separation system is adopted.

Dust emission is less than 30mg/m3, and the environmental protection index reaches the European standard;

Easy replacement of filter element.

Integrated design, maintainability increased by 95%.

A dust collector with high cost performance.

Machine Model | DC-4 | DC-6 | DC-9 | DC-12 | DC-24 | DC-48 | |

Application | Equipped with shot blasting machine | ||||||

Fan Power (kw) | 3KW | 5.5KW | 7.5KW | 11KW | 22KW | 37KW | 45KW |

Air Volume(CFM) | ≤4300 | ≤5000 | ≤9100 | ≤18000 | ≤23000 | ≤28000 | ≤25000~38000 |

Air pressure(Mpa) | ≤1100 | ≤2600 | ≤2100 | ≤2200 | ≤2800 | ≤2800 | ≤3900~3200 |

Dust Emissions(mg/m3) | ≤50 | ||||||

Total weigh(ton) | 0.6T | 0.85T | 1.2T | 1.5T(Exclude the fan) | 2.5(Exclude the fan) | 3T(Exclude the fan) | 6T(Exclude the fan) |

| Equipment Dimension(Length*Windth*Height) (mm) | 1319*1268*3911 | 1864*1508*3776 | 2400*2200*3060 | 3450*2230*3060 | 4730*2900*3760 | 7980*2900*3760 | |