Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

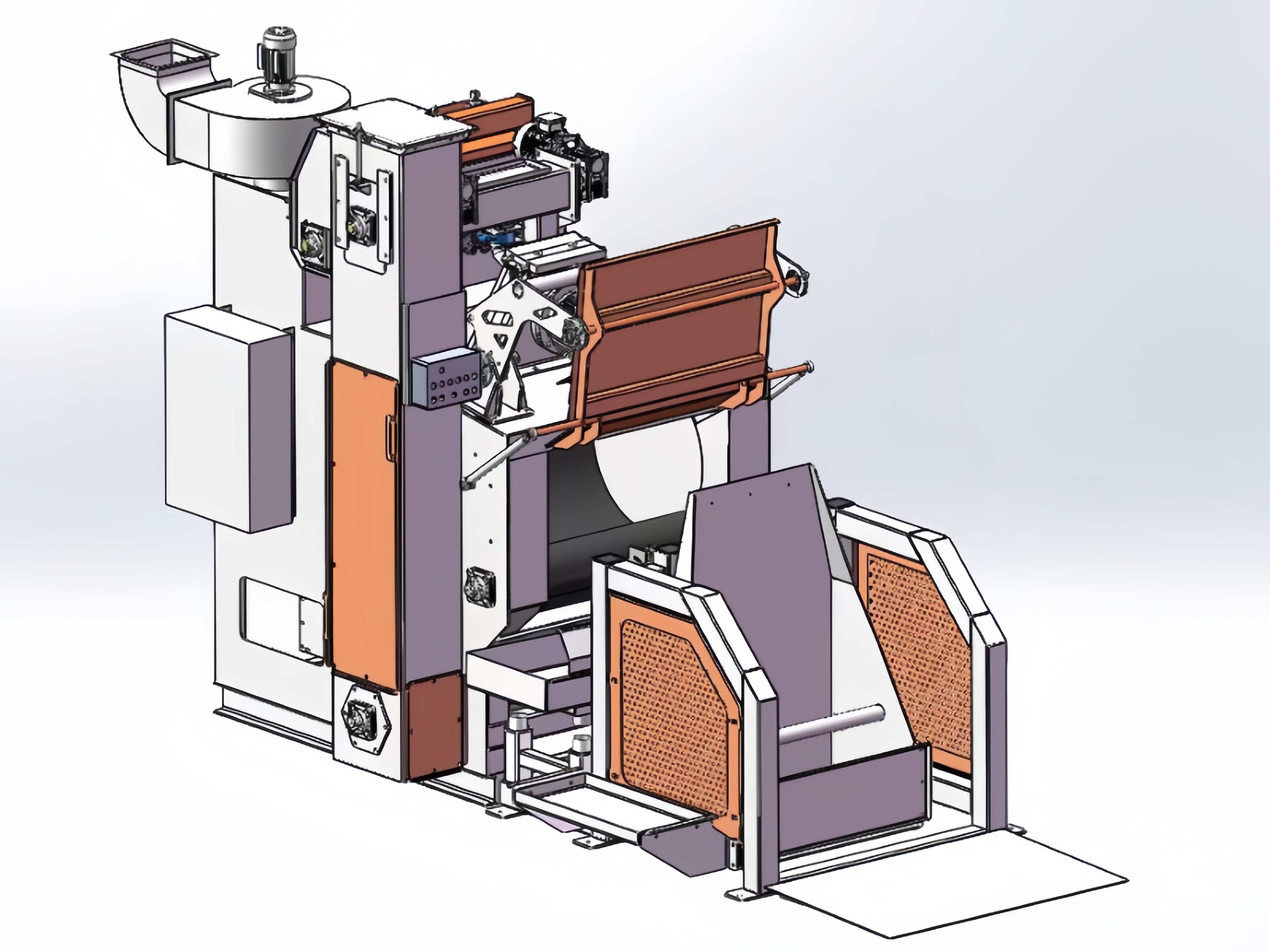

Bead blasting machines are highly sought after in industries that require a gentle yet effective surface treatment. These machines use small glass beads or other abrasive media to create a smooth and uniform finish on various materials. Bead blasting is ideal for applications where a delicate touch is needed, such as in the aerospace, automotive, and jewelry industries.

The process of bead blasting involves propelling the abrasive beads at a controlled velocity onto the surface to be treated. This removes any imperfections and leaves a clean, satin-like finish. Bead blasting machines come in different sizes and types, including cabinet models and portable units. Cabinet bead blasters offer a contained environment for blasting, reducing dust and debris. Portable bead blasters are convenient for on-site work and can be easily transported.

One of the advantages of bead blasting machines is their versatility. They can be used on a wide range of materials such as metals, plastics, and composites. Additionally, bead blasting can be adjusted to achieve different finishes, from a light matte to a more polished look. When shopping for a bead blasting machine, consider factors such as the size of your workpieces, the required blasting pressure, and the type of abrasive media available.