Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

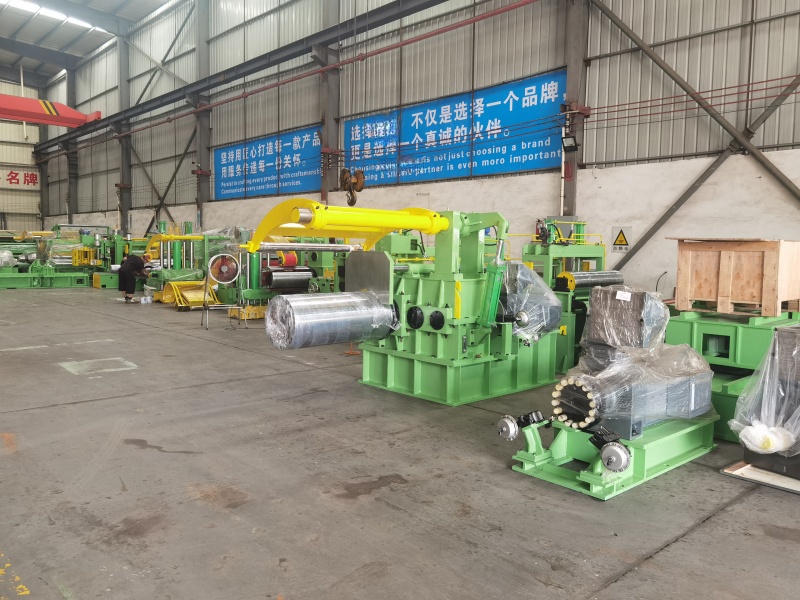

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

Standing seam metal roofs are known for their durability, aesthetic appeal, and energy efficiency. These roofs consist of interlocking metal panels that create a continuous, watertight surface. To produce standing seam metal roofs, specialized standing seam metal roof machines are required.

A standing seam metal roof machine is a sophisticated piece of equipment that is designed to form and join the metal panels in a precise and efficient manner. These machines typically consist of a series of rollers, presses, and cutting tools that work together to shape the metal and create the standing seams.

The process of using a standing seam metal roof machine begins with the selection of the appropriate metal sheet. Common materials used for standing seam roofs include steel, aluminum, and copper. The metal sheet is then fed into the machine, where it passes through a series of rollers that gradually bend and shape it into the desired profile.

One of the key features of a standing seam metal roof machine is its ability to create a tight and secure seam. The machine uses a combination of pressure and mechanical locking mechanisms to ensure that the panels are joined together firmly and without any gaps or leaks. This not only provides excellent waterproofing but also enhances the structural integrity of the roof.

Another advantage of standing seam metal roof machines is their flexibility in terms of panel design and customization. Manufacturers can adjust the settings of the machine to create different panel profiles, lengths, and widths, allowing them to meet the specific requirements of different projects. Additionally, some machines can be equipped with additional features such as embossing, perforating, or coating capabilities, further enhancing the functionality and appearance of the metal roof panels.

In addition to producing standard standing seam metal roof panels, some machines can also be used to create curved or tapered panels. This allows for the creation of unique roof designs and can add an extra level of aesthetic appeal to a building.

When considering the purchase of a standing seam metal roof machine, there are several factors to take into account. First, it is important to assess the production requirements and volume of panels needed. This will help determine the appropriate size and capacity of the machine. Additionally, factors such as the quality of the machine's construction, ease of operation, and availability of spare parts and technical support should also be considered.

Another important consideration is the compatibility of the machine with different types of metal materials. Some machines may be designed specifically for certain metals, while others may be more versatile and able to handle a variety of materials. It is important to choose a machine that can work with the materials that are most commonly used in the intended applications.

In conclusion, standing seam metal roof machines are essential tools for the production of high-quality standing seam metal roofs. Their ability to create tight seams, offer flexibility in design, and produce panels efficiently makes them a valuable investment for manufacturers in the construction industry. By choosing the right machine and considering factors such as production requirements, quality, and compatibility, manufacturers can ensure the success of their standing seam metal roof projects and provide customers with durable and attractive roofing solutions.