Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

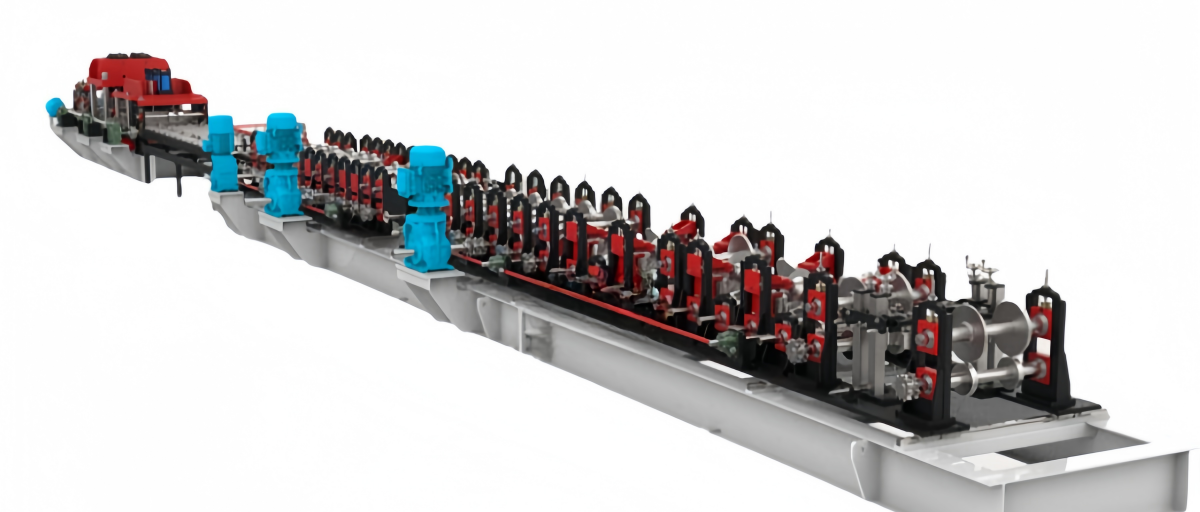

1.Name:Cable Tray Rolling Forming Machine

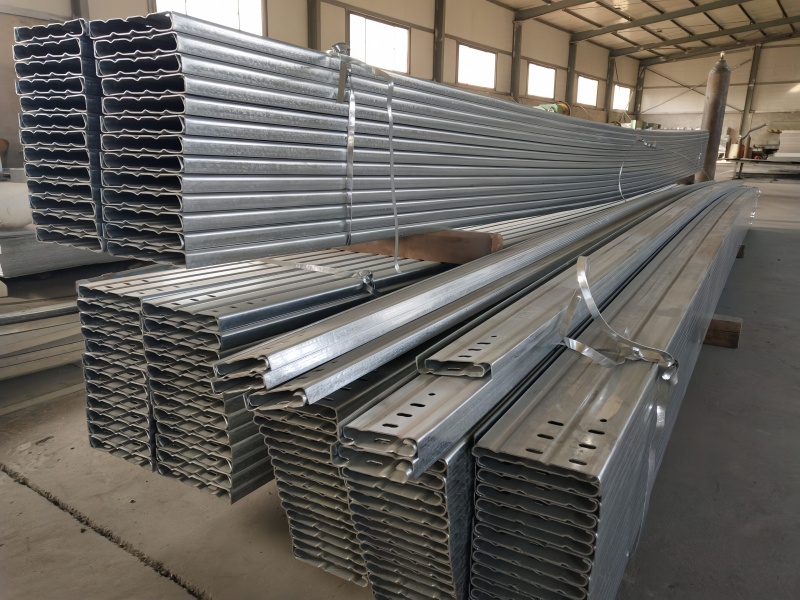

2.Application: Making Cable Tray

3.It can custom-design

Application

A Cable Tray Rolling Forming Machine is specifically designed for manufacturing cable trays, cable ladders, and cable bridges. It is widely used in construction, industrial, power, and communication sectors.

Main Components

1.Uncoiling Device: Used to unwind metal coils. Common types include manual uncoiling and hydraulic uncoiling.

2.Leveling Device: This component is used to flatten the metal strip to ensure the precision of subsequent processing.

3.Punching Device: It performs punching operations on the metal strip according to different requirements.

4.Roll Forming Device: Through multiple sets of rollers, the metal strip is gradually rolled into the shape of a cable tray.

5.Cutting Device: It cuts the formed cable tray to the specified length.

6.Control System: Typically using PLC control with a touch screen interface, it enables automated production.

Technical Parameters

Parameter | Description |

Material Suitable for Processing | Galvanized steel, carbon steel, cold-rolled steel, stainless steel, etc. |

Material Thickness | 0.6-2.0mm |

Material Width | 100-860mm |

Forming Speed | 4-20m/min |

Main Motor Power | 5.5KW-30KW |

Roll Material | GCr15 (quenched) |

Machine Structure | Cantilever or gantry style |

Control System | PLC control with touch screen interface |

Advantages

1.High Efficiency: The automated production process significantly increases productivity.

2.High Precision: The precise roll forming process ensures product quality.

3.Versatility: It can produce cable trays of different specifications and shapes according to customer needs.

4.Ease of Operation: Equipped with a touch screen interface, it is easy to learn and operate.

Application Scenarios

1.Construction Industry: Used for cable management in commercial and industrial buildings.

2.Power Industry: Used for cable support and protection in power facilities.

3.Communication Industry: Used for cable routing and management in communication systems.

If you need more detailed technical parameters or customized services, it is recommended to contact professional equipment manufacturers, such as MIZHI.