Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Name:Catenary Through Shot Blasting Machine

2.Model:MCT

3.Transport Mode: The Suspension Hooks Passes Continuously

The Catenary Through Shot Blasting Machine is a highly efficient industrial solution designed for surface preparation and cleaning of metal components. It is widely used in various industries such as automotive, machinery manufacturing, and steel structures. This machine is particularly effective for removing rust, scale, and other surface contaminants, while also enhancing the fatigue resistance of metal parts through shot peening.

Features

1.Continuous Operation: The machine supports continuous pass-through shot blasting, allowing for high production efficiency.

2.Automated Transport: Equipped with an automatic rapid transport system, it can handle workpieces continuously, reducing labor intensity.

3.Modular Design: The modular structure allows for easy integration into existing production lines, facilitating automated production.

4.Versatility: Suitable for a wide range of workpiece sizes and shapes, making it adaptable to various production requirements.

5.Energy Efficiency: Designed to minimize energy consumption and reduce maintenance costs.

6.Safety: Advanced safety features, including emergency stop buttons and safety guards, ensure safe operation.

Applications

The Catenary Through Shot Blasting Machine is used in multiple industries for the following applications:

1.Automotive Industry: Cleaning and strengthening of engine parts, cylinder caps, and motor casings.

2.Steel Structures: Surface treatment of large structural components.

3.Casting and Forging: Removing sand, scale, and rust from castings and forgings.

4.Machinery Manufacturing: Preparing parts for painting or other surface treatments.

Working Process

1.Loading: Workpieces are statically loaded onto hooks or hangers.

2.Transportation: The workpieces are transported through the machine via an overhead conveyor system.

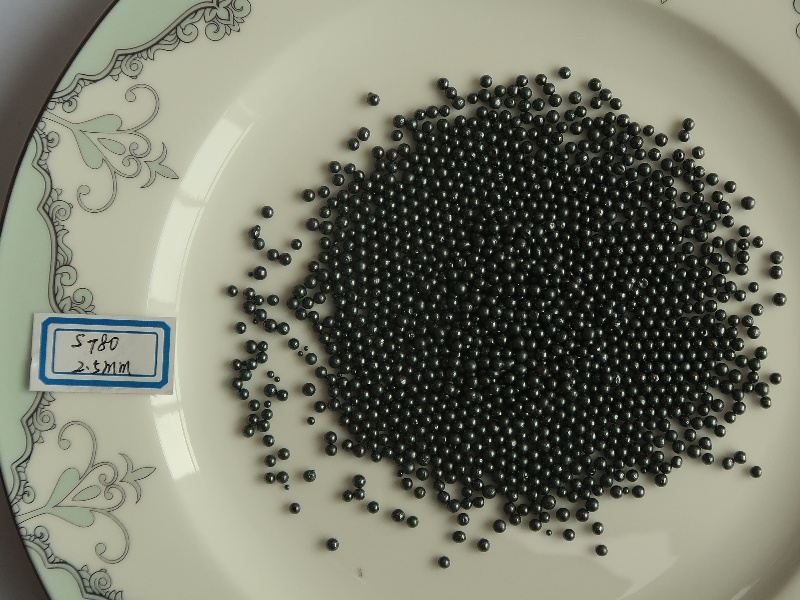

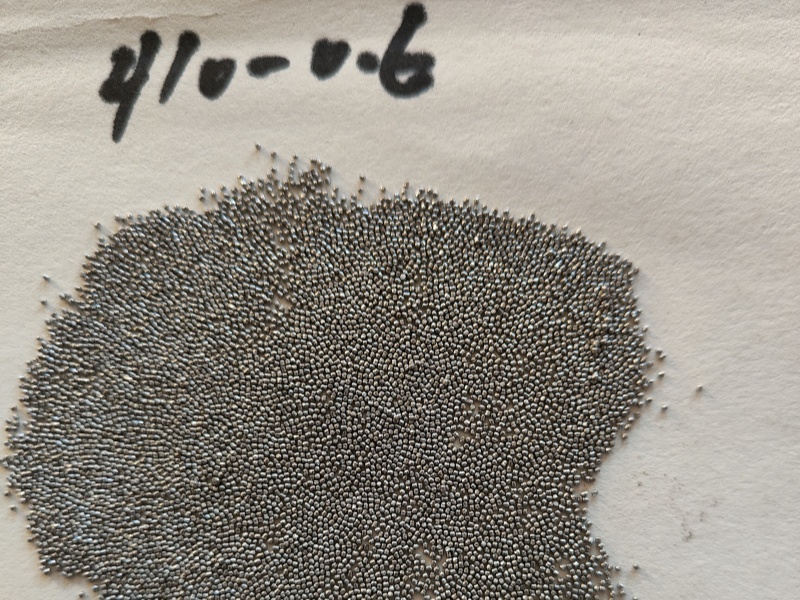

3.Blasting: High-speed steel shot or other abrasive media are propelled onto the workpieces by centrifugal force from the blasting wheels.

4.Cleaning: The shot media impact the surface, removing contaminants and improving surface quality.

5.Recovery and Recycling: The used shot media are collected, separated from debris, and recycled for reuse.

6.Unloading: Cleaned workpieces are unloaded from the machine.

Components

The machine typically consists of the following key components:

1.Overhead Conveyor System: Transports workpieces through the machine.

2.Blasting Chambers: Enclosed areas where the blasting process occurs.

3.Blasting Wheels: High-speed wheels that propel the shot media.

4.Shot Recycling System: Collects and recycles the used shot media.

5.Dust Collection System: Removes dust and debris generated during the blasting process.

6.Control Panel: Allows operators to adjust blasting parameters and monitor the process.

Advantages

1.High Production Efficiency: Continuous operation and high-speed transport ensure high output.

2.Cost-Effective: Low energy consumption and reduced maintenance requirements.

3.User-Friendly: Easy to operate and adjust, with user-friendly controls.

4.Durability: Manufactured using high-quality materials and advanced technology.

5.Flexibility: Suitable for various workpiece sizes and production requirements.

The Catenary Through Shot Blasting Machine is an ideal choice for industries requiring efficient and reliable surface preparation and cleaning of metal components.