Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Name: 1850MM High Speed Fly Shear Machine Line

2.Cutting Material: Metal Coil

3.Cutter QTY: 1 set

4.The Max. Coil Width:1850mm

What is High Speed Fly Shear Machine Line?

A High Speed Fly Shear Machine Line is an advanced industrial equipment used primarily in the metal processing industry for cutting metal coils into specific lengths with high precision and speed. Here's an overview of its key features and functions:

1.Operation Principle: The line operates by unwinding metal coils, leveling them, and then cutting them to length using a high-speed rotary shear. This process is continuous and does not require the material to stop during cutting, which increases efficiency.

2.Applications: It is used for processing various materials such as aluminum plates, cold-rolled plates, electrolytic galvanized plates, hot dip galvanized plates, color-coated plates, stainless steel plates, and copper plates.

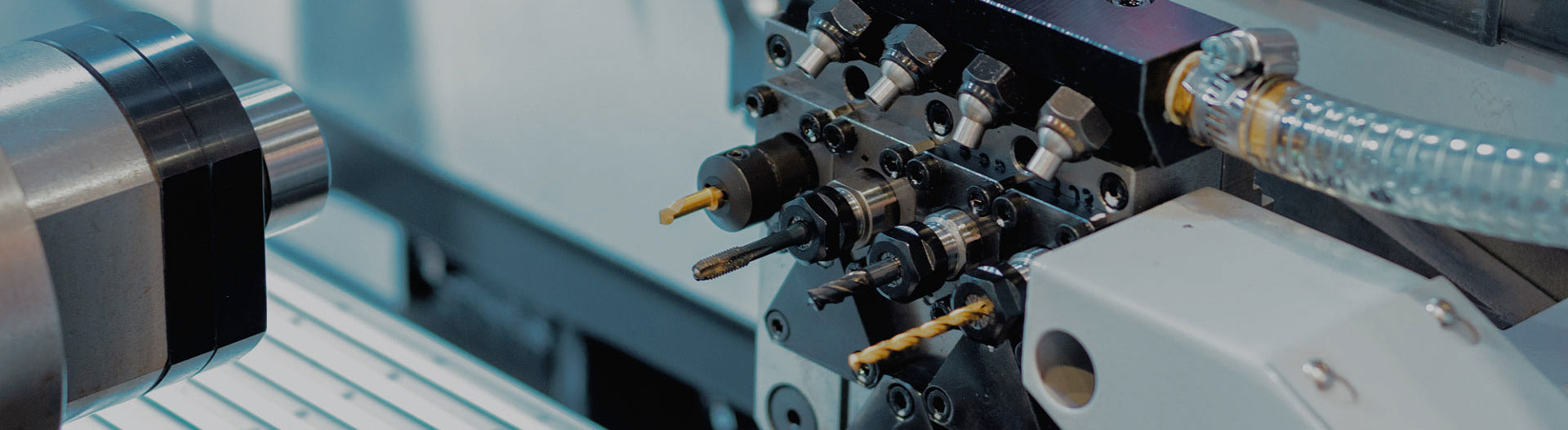

3.Components: The line typically consists of an entry coil car, uncoiler, precision leveler, film applicator, measure length roller, rotary shear machine, belt conveyor, and stacker.

4.Technical Parameters: Different models of high-speed fly shear lines can handle different material thicknesses, widths, and have specific finished lengths. They also have specified accuracy levels for length, diagonal accuracy, leveling accuracy, and line speed. For example, some models can handle material thicknesses from 0.1-1.0mm and have a line speed of up to 90 m/min.

5.Advantages:

(1).High Precision: The cutting length accuracy can be within ±0.3 mm, ensuring that the cut pieces meet strict dimensional requirements.

(2).High Speed: Some advanced models can operate at speeds up to 100 m/min, significantly increasing production output.

(3).Versatility: Capable of processing a variety of metal materials, including those with high strength and color galvanized steel coils.

(4).Environmental and Energy-Efficient: As they are designed to be more efficient, they can also contribute to energy savings and reduced environmental impact。

6.Customization: The lines can be customized to meet specific production needs, such as different material thicknesses, widths, and coil weights.

7.Control Systems: PLC (Programmable Logic Controller) systems are commonly used for controlling the operation of the line, allowing for automated and precise control over the cutting process.

8.Cutting Capacity: High Speed Fly Shear Machine Lines are capable of cutting a wide range of materials with different thicknesses and widths, making them versatile for various industrial applications.

In summary, a High Speed Fly Shear Machine Line is a critical piece of equipment in metal processing that offers high-speed, precision cutting of metal coils into specific lengths, enhancing production efficiency and output quality.

How does it ensure such high precision in cutting?

High Speed Fly Shear Machine Lines ensure high precision in cutting through several key mechanisms and technologies:

1.Advanced Control Systems: These lines are equipped with PLC (Programmable Logic Controller) and CNC (Computer Numerical Control) systems that offer precise length cutting with minimal tolerance. These systems are designed to control the cutting process with high accuracy, ensuring that each cut is made to the exact specifications required.

2.High-Speed Cutting Technology: The fly shear technology used in these lines allows for continuous operation, which means the cutting process can occur without stopping the material feed. This results in a significant increase in production efficiency and allows for faster cutting speeds while maintaining precision.

3.Rotary Shear Cutting: The rotary shear cuts the material in a single, fast stroke, which is particularly suitable for thin sheets. The sheet runs at a stable speed, and the rotary shear rotates to cut off a sheet in a cycle under closed-loop length feedback. This method can achieve a high cutting frequency, up to 150 times per minute, with linear production speeds up to 80 meters per minute

4.Leveling Technology: The incorporation of the latest leveling technology reduces the occurrence of buckling that may arise with traditional leveling methods. This ensures that the material is properly aligned and tensioned before cutting, which contributes to the precision of the cut.

5.High-Quality Components: The use of top-tier components such as German brand Flender gearboxes and advanced electrical control systems from Siemens and Bosch Rexroth enhances the cutting accuracy and speed, surpassing that of typical equipment.

6.Digital Drive Technology: Modern High Speed Fly Shear Machine Lines use digital drives instead of the traditional analog connection between the CNC and drives. Digital control technology is used to control the position, speed, and torque of the motor, with measuring systems reporting the actual position of the axes very accurately. This increases productivity and tool accuracy through complex control algorithms that minimize contour errors and machine rigidity problems.

7.Look Ahead Feedrate Control: Modern CNC systems for high-speed machining use look ahead feedrate control, which identifies irregular block transitions and excessive axis acceleration caused by path curvature. This control strategy eliminates contour error and ensures greater path accuracy at high tool path feedrates.

8.High-Resolution Digital Monitoring: Digital drive control supports high-resolution digital speed and path monitoring, which is crucial for maintaining precision during high-speed operations.

9.Compensation of Mechanically Induced Errors: High Speed Fly Shear Machine Lines are capable of compensating for mechanically induced errors, which can affect the precision of the cut. This compensation ensures that the final product meets the required specifications.

These features and technologies work together to ensure that High Speed Fly Shear Machine Lines can achieve high precision in cutting, which is essential for maintaining product quality and efficiency in various industrial applications.