Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Model No.: DBMT

2.Applicable Coil Width: 20mm-300mm

3.Applicable Coil Thickness: 0.3-3.5mm

4.Coil Inner Diameter: 450-530mm

5.Coil Outer Diameter: 1200mm

6.Speed: 15m/min

7.Applications: Pressing Line/Metal Stamping Line/Forming Line

Aiming to reduce the time to load a roll to the minimum point, this double head decoiler type drives one of the rolls, as the other one waits as a backup.

When the driven roll is over, the backup roll will be ready to be connected to the driver within a very short period of time. When you connect the new roll to the driver, you will have a long time to load another spare roll. Double head decoiler is an ideal solution for production plants where production speed and continuity are crucial in serial manufacturing. So usually configured with the S loop straightener, high speed gear machine and H frame high speed press machine, it’s usually suitable for motor rotor and stator lamination stamping.

Model No.: DBMT

Applications: Pressing Line/Metal Stamping Line/Forming Line

Applicable Coil Width: 20mm-300mm

Applicable Coil Thickness: 0.3-3.5mm

Coil Inner Diameter: 450-530mm

Coil Outer Diameter: 1200mm

Speed: 15m/min

Mandrel Expansion: Manual

Application: Uncoiling the coils

Ideal for high speed lamination stamping line

Usually, double head decoiler machine is equipped with the high speed press machine.

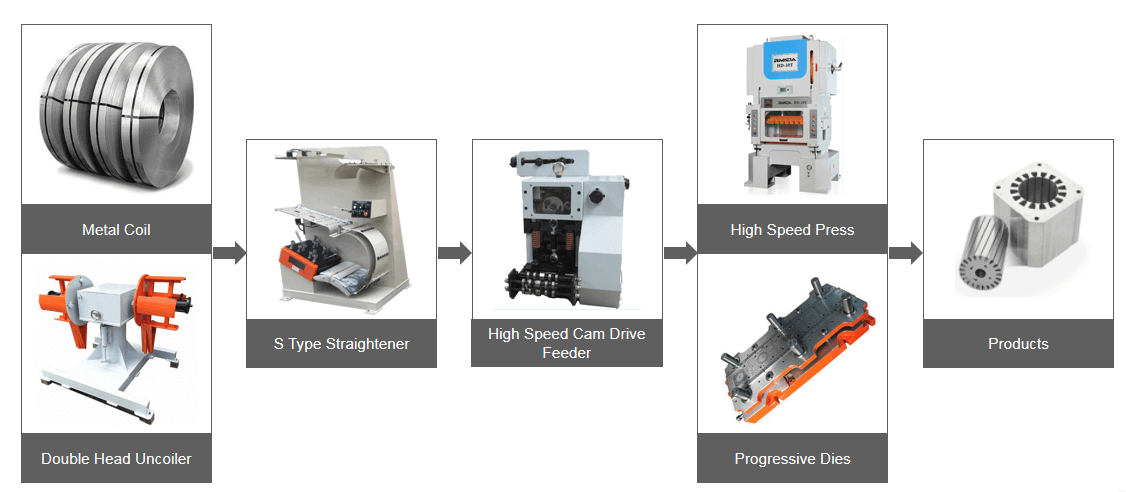

This high speed coil feeding line combined double head decoiler, s-loop straightener, and cam feeder, speed can reach 60m per minute, design for motor and EI lamination stamping.

The configuration of high speed press line for Motor and EI lamination

Step-1: Double Head Decoiler machine, Loading coil and uncoilling coil.

Step-2: High speed S Loop Straightener machine, leveling the strips.

Step-3: High speed Cam Feeder machine, Feed coil to press machine.

Step-4: High speed press machine with the moulds,pressing to the end product

Model | DBMT-200 | DBMT-300 |

Coil Width (mm) | ~200 | ~300 |

Coil Thickness (mm) | 0.1 - 1.6 | |

Coil I.D. (mm) | 450 - 530 | |

Coil O.D. (mm) | 1200 | |

Loading Capacity (kgs) | 500 + 500 | 1000 + 1000 |

Spindle Expansion | Manual | |

Pressing Arm | Optional | |

Power (HP) | Non-motorized | |

Inverter | Without | |