Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

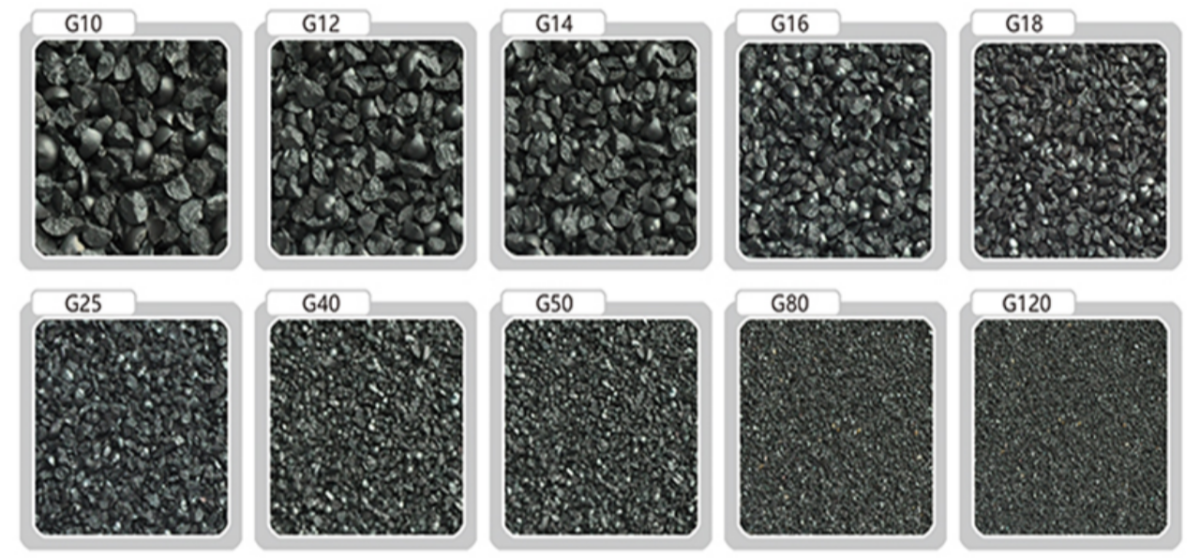

GP Steel Grit is a type of cast steel abrasive designed for surface treatment and cleaning applications. It is characterized by its lower hardness and durability, making it suitable for specific industrial tasks.

Characteristics

1.Hardness: GP steel grit has a hardness range of 42-52 HRC. This makes it softer compared to GL and GH steel grit.

2.Shape: Initially sharp-edged, GP steel grit quickly becomes rounded during use. This characteristic reduces its aggressiveness and makes it less likely to damage delicate surfaces.

3.Chemical Composition:

Carbon (C): 0.80-1.20%

Manganese (Mn): 0.60-1.20%

Silicon (Si): ≥0.40%

Sulfur (S): ≤0.05%

Phosphorus (P): ≤0.05%

Density: Approximately 7.3-7.6 g/cm³.

Microstructure: Consists of tempered martensite or sorbite.

Applications

GP steel grit is particularly suitable for:

1.Surface Cleaning: Removing oxide scale and rust from steel surfaces.

2.Pre-Treatment: Preparing surfaces for coating or painting by creating a clean, uniform profile.

3.Foundry Operations: Cleaning and desanding castings.

4.Deburring: Removing burrs from metal parts.

Advantages

1.Efficiency: The angular edges of GP steel grit allow it to remove contaminants effectively.

2.Durability: Despite its lower hardness, GP steel grit is designed to withstand multiple uses.

3.Recyclability: GP steel grit can be reused multiple times, reducing waste and operational costs.

4.Surface Finish: It provides a uniform etched surface profile, enhancing the adhesion of subsequent coatings.

Usage Considerations

1.Equipment Compatibility: GP steel grit is commonly used in wheel blast machines. Its softer nature makes it less abrasive on machine components compared to harder grits like GH.

2.Surface Protection: Due to its lower hardness, GP steel grit is less likely to cause surface damage, making it suitable for delicate or thin-walled parts.

In summary, GP steel grit is an effective and versatile abrasive material, ideal for applications requiring a balance of cleaning efficiency and surface protection. Its recyclability and durability further enhance its value in industrial processes.

Hardness Tester

1. No friction spindle,High testing accuracy.

2. Stable construction,High testing efficiency.

3. High precision micrometer readings metering system.

4. Testing process automation,no human operator error.

5. Accuracy class:GB/T4340.2/ISO6507-2 and American ASTME92.

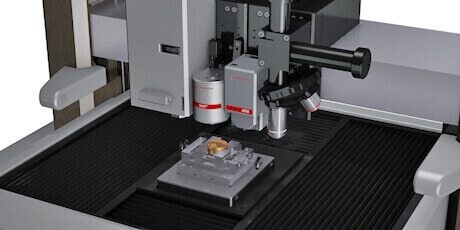

Microscope

1. To identificate and analyze the organizational structure of various metals and alloys.

2. The instrument is widely used in factories or laboratories to identify the quality of castings,inspect raw materials,or Microstructure analysis after-treatment.

Three Element Analyzer

1. A newer multi-element analyzer.

2. It is used in detection of variety of elements such as :Si/Mn/P/Cr/Ni/Mo/Cu/Ti of all kinds of material such as:ball mill cast iron,cast iron,ductile iron,alloy cast iron and stainless steel ,carbon steel,low alloy steel,high alloy steel etc. The analysis result is fast and accurate.

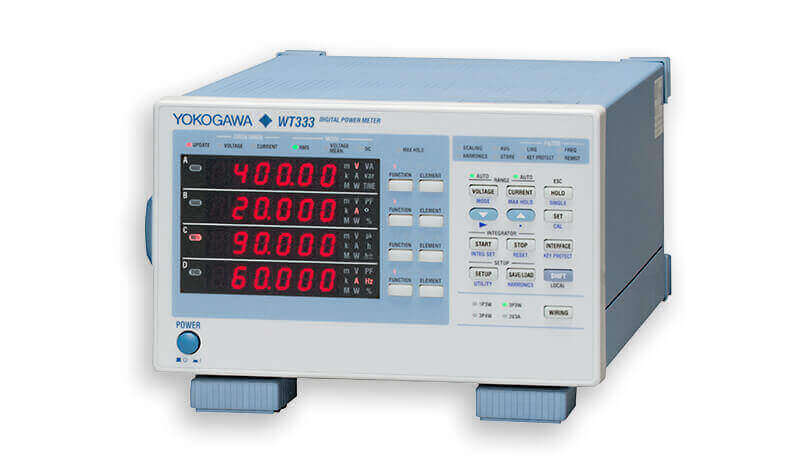

Carbon & Sulfur Analyzer

1. The equipment is one of the high-tech products and a collection of optical ,mechanical and electrical ,computer,analysis technology.

2. It has the advantage of wide measuring range,strong anti-jamming capability,complete functions,simple operation,analysis results accurate and reliable,ti is the ideal analysis equipment of the 2 element of carbon and sulfur in industries determination.