Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

Overview

An H Beam Shot Blasting Machine is a specialized industrial equipment designed to clean, descale, and surface-treat H-beams (also known as I-beams or wide flange beams). This machine is widely used in the steel manufacturing, construction, and metal fabrication industries to prepare H-beams for further processing, such as painting, welding, or galvanizing.

Working Principle

The primary function of an H Beam Shot Blasting Machine is to remove rust, scale, and other contaminants from the surface of H-beams using abrasive media (such as steel shot or grit).

The machine operates through the following key processes:

1.Loading:

H-beams are loaded into the blasting chamber manually or using an automated loading system. The beams are typically placed on a conveyor system that moves them through the machine.

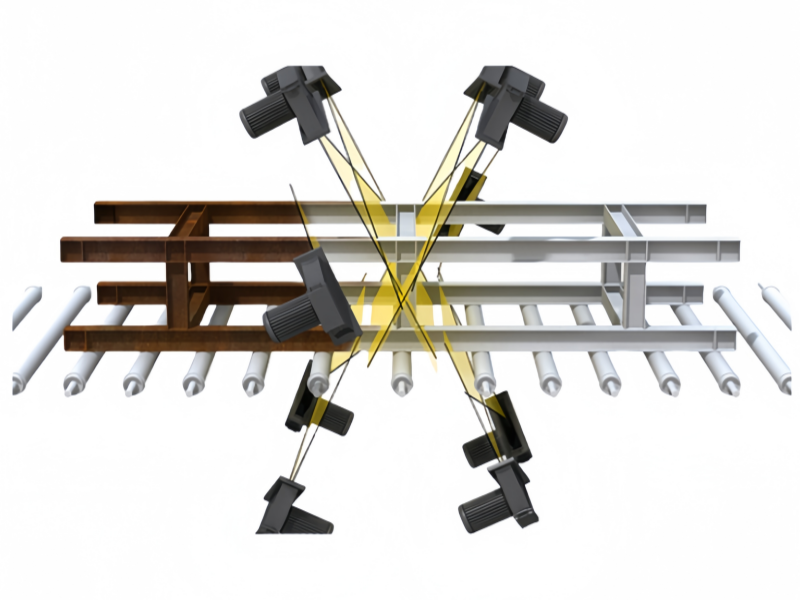

2.Blasting:

Inside the blasting chamber, high-speed blast wheels or turbines propel the abrasive media onto the surface of the H-beams. The impact of the media removes rust, scale, and other impurities, leaving a clean and roughened surface.

3.Media Recovery and Recycling:

The used abrasive media, along with debris and contaminants, falls to the bottom of the chamber. An elevator system lifts the mixture to a separator, where the reusable media is separated from the waste materials. The clean media is then recycled back into the blast wheels for reuse.

4.Dust Collection:

A dust collection system captures fine particles and dust generated during the blasting process, ensuring a clean working environment and compliance with environmental regulations.

5.Unloading:

After the blasting process is complete, the cleaned H-beams are unloaded from the machine, ready for further processing or inspection.

Key Components

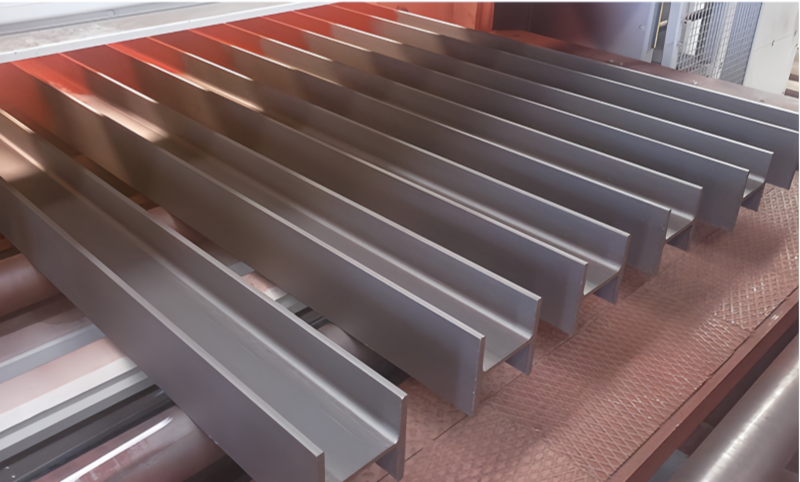

1.Blast Chamber:

A robust, enclosed chamber where the blasting process takes place. It is designed to contain the abrasive media and prevent it from escaping.

2.Blast Wheels/Turbines:

These components are responsible for propelling the abrasive media at high speeds. They are typically equipped with adjustable settings to control the intensity and direction of the blast.

3.Conveyor System:

The conveyor system moves the H-beams through the blast chamber. It can be designed to handle different sizes and weights of beams.

4.Media Recovery System:

This includes an elevator and a separator to collect and recycle the abrasive media. The system ensures efficient use of the media and reduces waste.

5.Dust Collector:

An essential component that captures and filters dust and fine particles generated during the blasting process. It helps maintain air quality and meets environmental standards.

6.Control Panel:

The control panel allows operators to monitor and adjust the machine's settings, such as blast intensity, conveyor speed, and media flow rate.

Advantages

1.High Efficiency:

The machine can process multiple H-beams quickly, making it suitable for high-volume production environments.

2.Surface Preparation:

The blasting process effectively removes rust, scale, and other contaminants, leaving a clean and roughened surface that is ideal for painting, welding, or galvanizing.

3.Automation:

Modern H Beam Shot Blasting Machines are often equipped with automated systems, reducing the need for manual labor and improving operational efficiency.

4.Environmental Compliance:

The inclusion of dust collection and media recycling systems ensures that the machine operates in an environmentally friendly manner.

5.Durability:

The machine is built with high-quality materials and components, ensuring long-term durability and reliability.

Applications

H Beam Shot Blasting Machines are used in various industries, including:

1.Steel Manufacturing:

To clean and prepare H-beams before they are used in construction or other applications.

2.Construction:

To ensure that H-beams are free from rust and contaminants, which can affect their structural integrity.

3.Metal Fabrication:

To prepare H-beams for welding, painting, or other surface treatments.

4.Automotive and Heavy Machinery:

To clean and treat H-beams used in the manufacturing of automotive parts and heavy machinery.

Maintenance Tips

1.Regular Inspection:

Regularly inspect the blast wheels, conveyor system, and dust collector to ensure they are in good working condition.

2.Media Management:

Monitor the quality and quantity of the abrasive media. Replace or replenish it as needed to maintain optimal blasting performance.

3.Dust Collector Maintenance:

Clean and maintain the dust collector to ensure it operates efficiently and complies with environmental regulations.

4.Safety Precautions:

Ensure that operators are trained in the safe operation of the machine and are equipped with appropriate personal protective equipment (PPE).

In summary, an H Beam Shot Blasting Machine is a vital tool in the steel and metal fabrication industries. Its ability to efficiently clean and prepare H-beams for further processing makes it an essential component in maintaining the quality and integrity of steel products.