Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

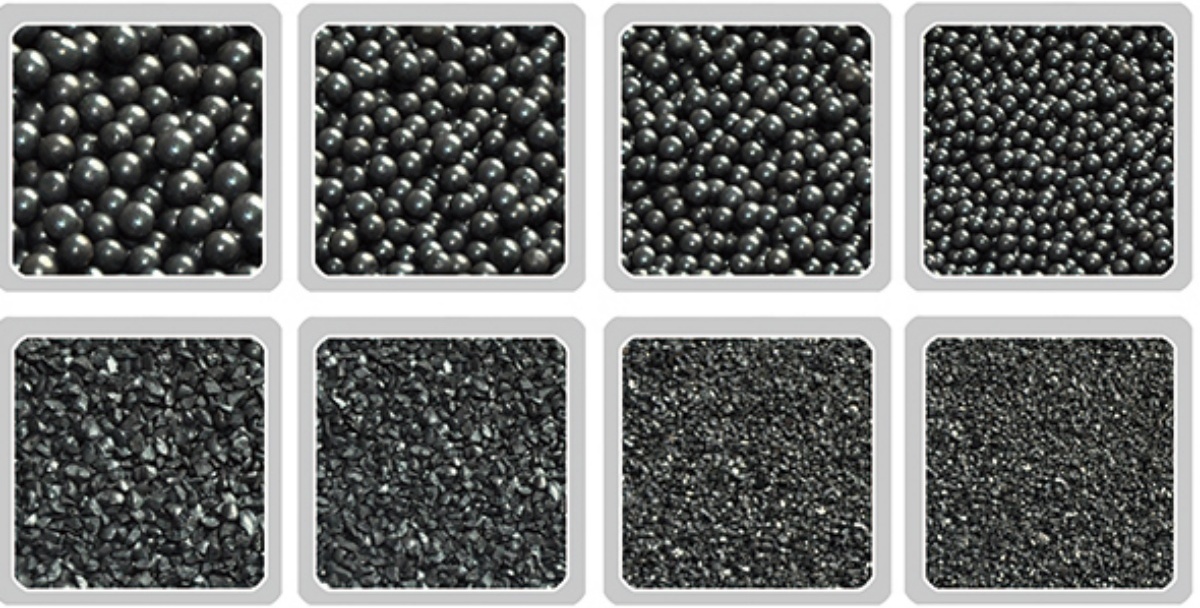

1.Name:Cast Steel Shot

2.Model: S50-S930

3.Hardness:HRC40-51

Definition

High-Carbon Steel Shot is a type of metallic abrasive medium that is highly efficient for surface preparation, cleaning, and finishing in industrial processes. It is characterized by its high hardness and durability, making it suitable for heavy-duty applications。

Characteristics

1.High Hardness: With a carbon content ranging from 0.85% to 1.20%, high-carbon steel shot has a typical hardness of 40-51 HRC。

2.Durability: It is highly durable and can withstand repeated impacts without breaking down easily, making it suitable for high-intensity operations。

3.Recyclability: High-carbon steel shot can be reused multiple times, providing an economical and environmentally friendly solution。

4.Uniformity: The shot is spherical in shape, ensuring consistent coverage and performance during blasting。

5.Density: It has a high specific density (not less than 7g/cc), which contributes to its effectiveness in cleaning and finishing。

Applications

High-carbon steel shot is used in a variety of industrial applications, including:

1.Descaling: Removing scale, rust, and other impurities from metal surfaces, commonly used in steel mills, foundries, and metal fabrication shops。

2.Shot Peening: Inducing compressive stresses on metal surfaces to improve fatigue resistance, widely used in the automotive, aerospace, and manufacturing industries。

3.Surface Cleaning: Removing dirt, oil, paint, and other unwanted coatings from metal surfaces。

4.Deburring: Removing sharp edges and burrs from machined or cut metal parts。

5.Surface Preparation: Preparing metal surfaces for coating or painting by creating a clean and roughened surface。

6.Sand Blasting: Cleaning and preparing surfaces by propelling high-carbon steel shot at high speeds。

7.Metal Finishing: Improving the surface quality and appearance of metal parts for a smooth and polished finish。

8.Casting Cleaning: Removing residual sand, scale, and contaminants from cast metal parts。

9.Pipe Cleaning: Removing rust, scale, and contaminants from the inner and outer surfaces of pipes。

10.Weld Cleaning: Cleaning slag, spatter, and contaminants from welded joints to enhance the weld's appearance and integrity。

Advantages

1.Efficiency: High hardness and density make it highly effective in cleaning and finishing, saving time and labor。

2.Cost-Effectiveness: Its recyclability reduces long-term operational costs。

3.Versatility: Suitable for a wide range of applications across different industries。

4.Reduced Dust: Compared to other abrasives, high-carbon steel shot generates less dust, leading to a cleaner working environment。

5.Surface Hardening: Shot peening with high-carbon steel shot can improve the fatigue life of components。

Selection Considerations

When choosing between high-carbon steel shot and other types of steel shot, consider the specific application, expected treatment effect, and overall cost-benefit analysis. High-carbon steel shot is ideal for heavy-duty applications requiring high hardness and wear resistance, while lower carbon options may be more suitable for delicate or less aggressive tasks。

In summary, high-carbon steel shot is a highly durable and versatile abrasive material that offers significant benefits in surface preparation and cleaning processes. Its high hardness, recyclability, and wide range of applications make it a preferred choice for many industrial operations。

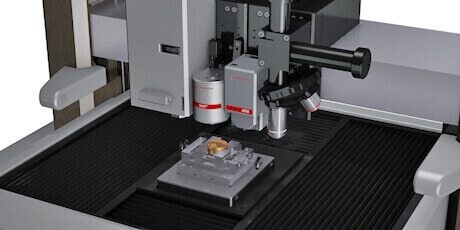

Hardness Tester

1. No friction spindle,High testing accuracy.

2. Stable construction,High testing efficiency.

3. High precision micrometer readings metering system.

4. Testing process automation,no human operator error.

5. Accuracy class:GB/T4340.2/ISO6507-2 and American ASTME92.

Microscope

1. To identificate and analyze the organizational structure of various metals and alloys.

2. The instrument is widely used in factories or laboratories to identify the quality of castings,inspect raw materials,or Microstructure analysis after-treatment.

Three Element Analyzer

1. A newer multi-element analyzer.

2. It is used in detection of variety of elements such as :Si/Mn/P/Cr/Ni/Mo/Cu/Ti of all kinds of material such as:ball mill cast iron,cast iron,ductile iron,alloy cast iron and stainless steel ,carbon steel,low alloy steel,high alloy steel etc. The analysis result is fast and accurate.

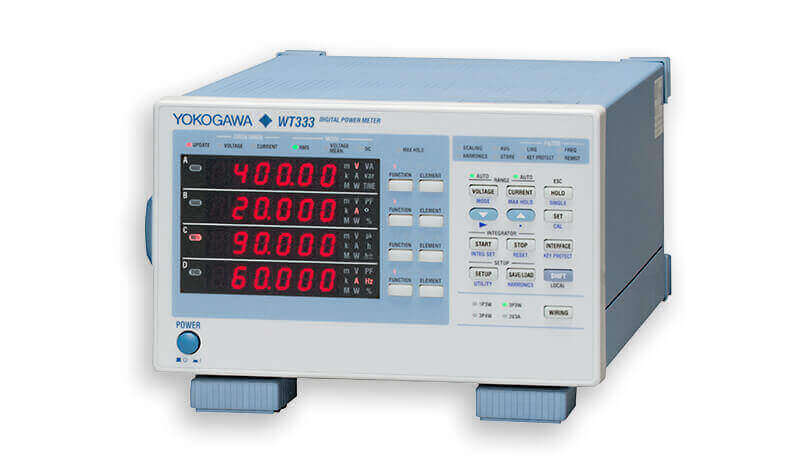

Carbon & Sulfur Analyzer

1. The equipment is one of the high-tech products and a collection of optical ,mechanical and electrical ,computer,analysis technology.

2. It has the advantage of wide measuring range,strong anti-jamming capability,complete functions,simple operation,analysis results accurate and reliable,ti is the ideal analysis equipment of the 2 element of carbon and sulfur in industries determination.