Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

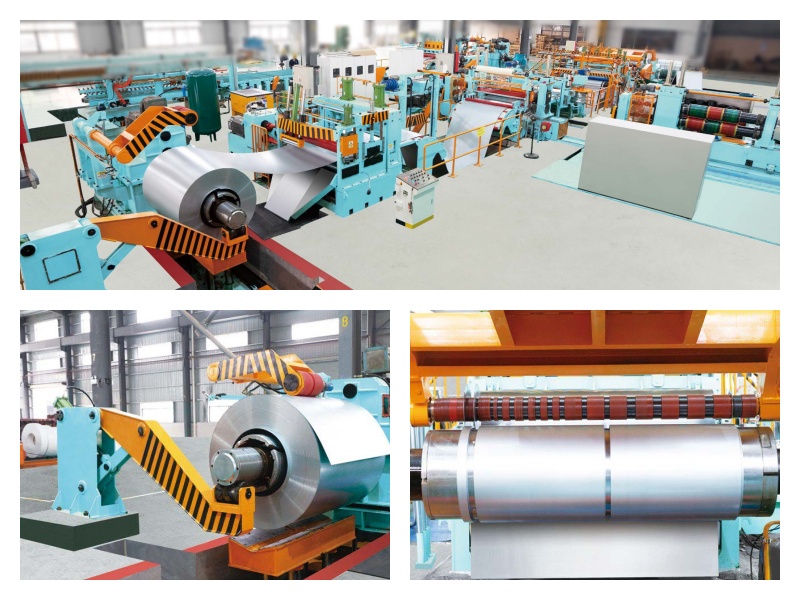

1.Name: Slitting Line

2.Slitting Material: Metal Coil

3.Slitter QTY: 2 sets

4.The Max. Coil Width:1650mm

What are the key components of a slitting line?

The key components of a slitting line are essential for its operation and contribute to its efficiency and precision. Here's a list of the main components:

1.Uncoiler: This component is responsible for unwinding the large steel coil and feeding it into the slitting line. It must be properly aligned to ensure smooth and consistent feeding.

2.Payoff Stand: Sometimes used in place of or in addition to an uncoiler, it helps in supporting and unwinding the heavy coils.

3.Entry Guide or Aligner: Guides the material from the uncoiler into the slitting section, ensuring that the material is properly aligned for accurate slitting.

4.Slitter Head: The central part of the slitting line that houses the rotary blades or knives. It performs the actual cutting of the material into narrower strips. The slitter head can be adjusted to change the width of the slit material.

5.Blades or Knives: The cutting tools within the slitter head that slice the material. They come in various types, such as razor blades, shear blades, or scoring blades, depending on the material and the required finish.

6.Tension Control System: Regulates the tension on the material as it passes through the slitting line, ensuring consistent tension for accurate and uniform slitting.

7.Edge Trimmer: Removes the wavy or irregular edges produced by the slitting process, resulting in a neater and more uniform edge.

8.Rewinder: After the material has been slit, the rewinder collects the narrower strips and rewinds them into smaller coils for further processing or packaging.

9.Turret Rewinder: A type of rewinder that uses a turret to hold multiple cores, allowing for continuous operation without stopping to change cores.

10.Danish Eye or Spool: A type of winding mechanism that allows the material to be wound onto a core in a balanced and uniform manner.

11.Auto-Threading System: An automated system that threads the material through the slitting line without manual intervention, increasing efficiency and reducing downtime.

12.Control System: Manages the operation of the slitting line, including speed, tension, and blade settings. Modern control systems may include computerized interfaces for precise adjustments and monitoring.

13.Waste Winder: Collects and winds the waste material or edge trim removed during the slitting process.

14.Safety Guards and Shields: Protect operators from the moving parts of the slitting line and prevent accidents.

These components work together to ensure that the slitting line operates efficiently, producing high-quality, precision-cut material at high speeds.

What is slitting line ?

Slitting line is a type of industrial equipment used in metalworking and manufacturing processes. It is designed to cut wide coils of metal into narrower strips of specific widths. The process is typically used for materials like steel, aluminum, copper, and other metals with similar properties.

In a slitting line, the metal coil is unwound and fed through a series of rollers and blades that cut the coil into strips of desired widths. These strips are then rewound onto individual spools or recoiled into smaller coils for further processing or distribution.

Slitting lines are commonly used in industries such as automotive, construction, packaging, and appliances where precise and efficient cutting of metal coils is required to meet specific size and quality requirements. These lines can vary in complexity and capacity depending on the thickness and width of the material being processed.