Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

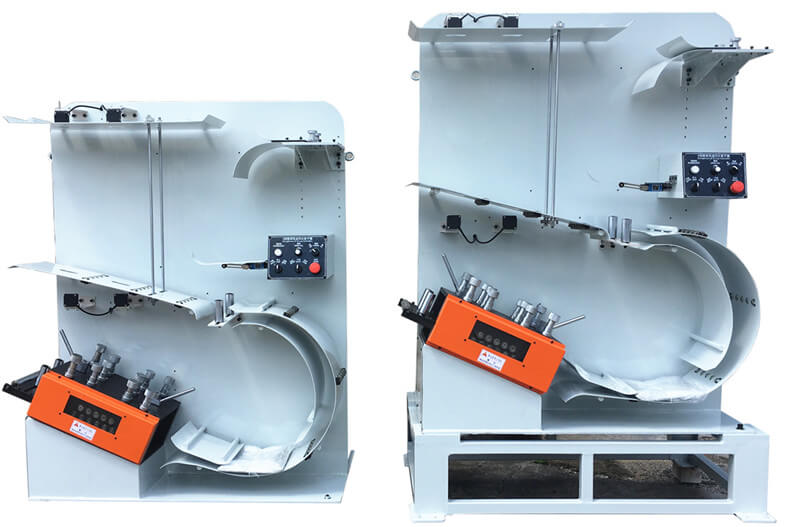

1.Model No.: JMS

2.Applications: Pressing Line/Metal Stamping Line

3.Applicable Coil Width: 20mm-300mm

4.Applicable Coil Thickness: 0.3-1.2mm

5.Speed: 60m/min

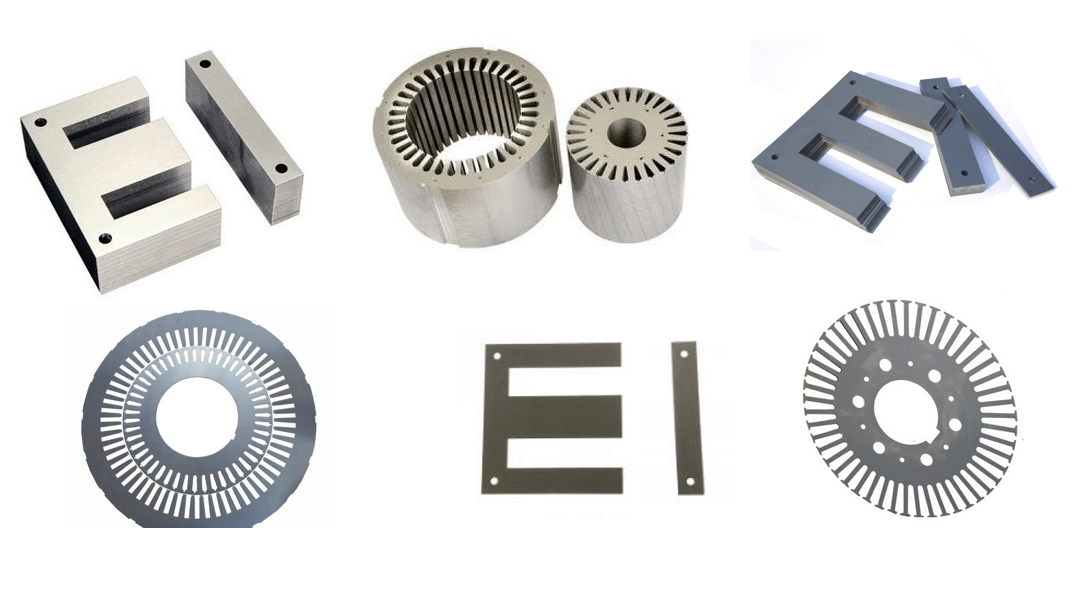

6.JMS is ideal for high speed Stator & rotor and EI lamination stamping line

S loop High speed straightener is a powerful new equipment for high speed stamping, which can improve the quality and quantity of punch products.It is impossible to produce a good punch by leveling the end of the coil material. Only by leveling the coil material can the stress be eliminated. After leveling by the machine, the material can be corrected to bend downward or flat.The transmission device and frequency converter (cycle control) can synchronize with the punch speed and balance the feeding.

The speed of S loop High speed straightener can reach 60m/min, and usually configured with the double head decoiler machine, high speed gear machine and H frame high speed press machine, it’s usually suitable for motor rotor and stator lamination stamping.

Model No.: JMS

Applications: Pressing Line/Metal Stamping Line

Applicable Coil Width: 20mm-300mm

Applicable Coil Thickness: 0.3-1.2mm

Speed: 60m/min

JMS is ideal for high speed Stator & rotor and EI lamination stamping line

JMS S-loop straightener is used in stator and rotor lamination stamping and EI lamination stamping line.

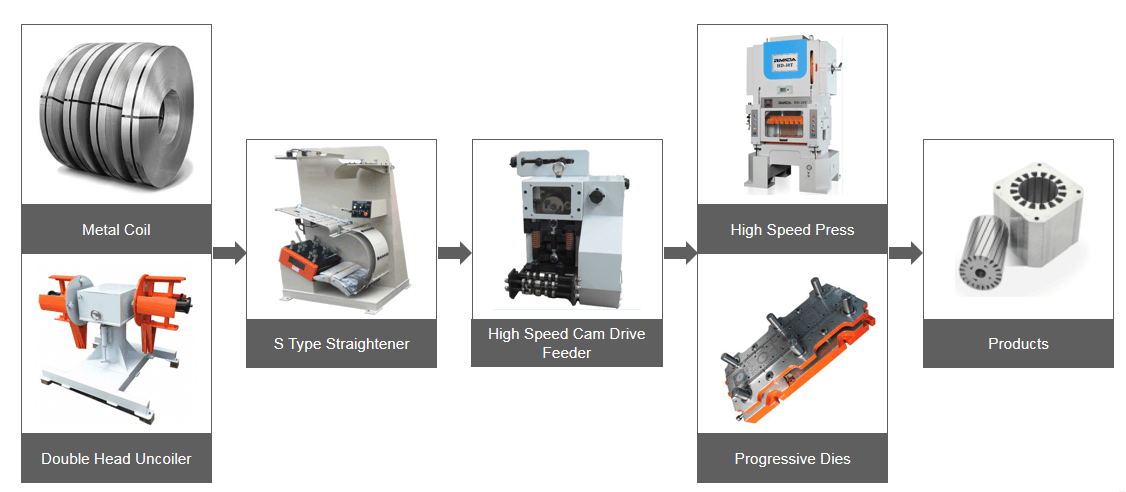

Step-1: Double Head Decoiler machine, Loading coil and uncoilling coil.

Step-2: High speed S Loop Straightener machine, leveling the strips.

Step-3: High speed Cam Feeder machine, Feed coil to press machine.

Step-4: High speed press machine with the moulds,pressing to the end product

Model | JMS-200 | JMS-300 |

Coil Width (mm) | ~200 | ~300 |

Coil Thickness (mm) | 0.1 - 1.2 | |

Feeding Speed | 0 - 60 m/min | |

Motor | 2HP | |

Inverter | Delta, Taiwan | |

Straightener Roller | 5pcs on top + 6pcs on bottom | |

Pinch Roller | 2pcs | |

Roller Adjustment | 4 points fine micro adjustment | |

Loop Control | Photo-electric Sensing Device | |