Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Name: Tumble Shot Blasting Machine

2.Model:Q326

3.Manul Open Door

A tumble shot blasting machine is a highly efficient industrial device used for surface treatment of various workpieces through a tumbling and blasting process.

Here is a detailed description based on the latest information:

Working Principle

Tumble shot blasting machines operate in batch mode, processing groups of workpieces together. The workpieces are loaded into a trough-shaped chamber equipped with a continuous rubber conveyor belt or a steel apron conveyor. As the workpieces move through the chamber, they are tumbled and blasted with steel shot or grit, which removes rust, scale, burrs, and other contaminants. The blasting media is propelled at high velocity by centrifugal wheels or turbines. After the blasting process, the workpieces are unloaded, and the used media is collected, separated, and recycled for reuse.

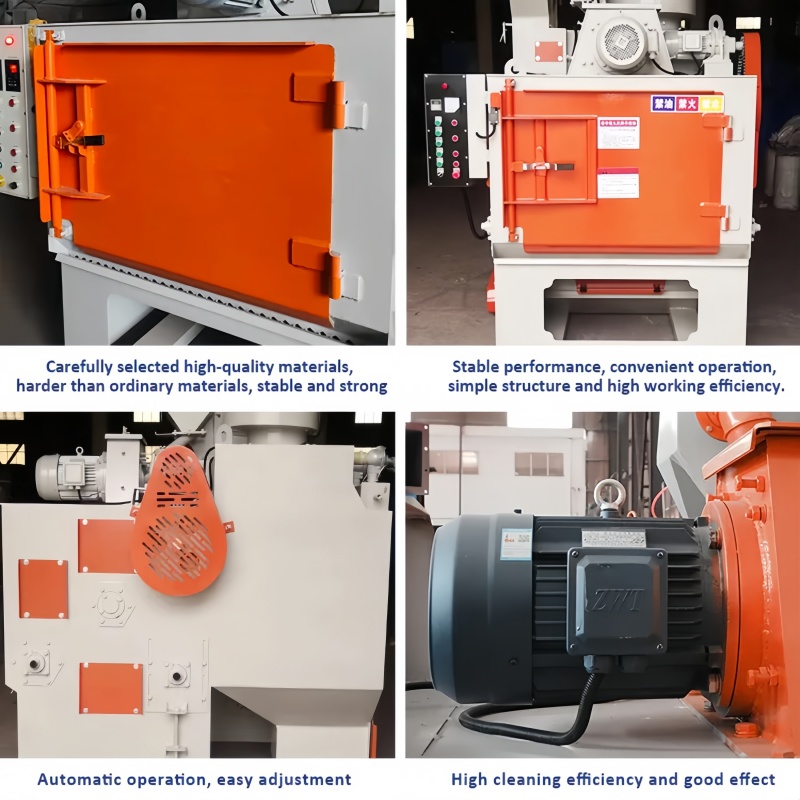

Structure and Components

1.Blasting Chamber: Made of strong profiles and thick steel plates, the chamber is designed to withstand high-velocity impacts. It features wear-resistant liners to protect against damage.

2.Tumble Belt System: The rubber or steel belt tumbles the workpieces, ensuring all surfaces are exposed to the blasting media. Rubber belts are suitable for lighter workpieces, while steel belts are used for heavier, more durable parts.

3.Blast Wheels/Turbines: These high-speed wheels propel the blasting media, providing efficient and consistent coverage. They are designed for long life and low maintenance.

4.Abrasive Recycling System: The used blasting media is collected via a screw conveyor and lifted by an elevator to a separator, which removes fines and recycles the usable media.

5.Dust Collection System: A cartridge-type dust collector captures dust particles with high efficiency (99.9%), ensuring a clean working environment.

Types and Variants

1.Batch Type Tumble Shot Blasting Machines: These machines process workpieces in batches, offering high efficiency and cost-effectiveness. They are suitable for a wide range of applications, from small plastic parts to large metal castings.

2.Continuous Feed Tumble Shot Blasting Machines: Designed for high production volumes, these machines allow for continuous processing of bulk goods.

Features and Advantages

1.Uniform Cleaning: The tumbling action ensures that all surfaces of the workpieces are evenly blasted, resulting in a high-quality finish.

2.Cost-Effective: The recycling of blasting media and batch processing make these machines economically efficient.

3.Versatility: Suitable for various materials and workpiece sizes, these machines can handle castings, forgings, heat-treated parts, and more.

4.Low Maintenance: Many models are designed with easy access to key components and low maintenance requirements.

5.Environmentally Friendly: The enclosed design and efficient dust collection system minimize environmental pollution.

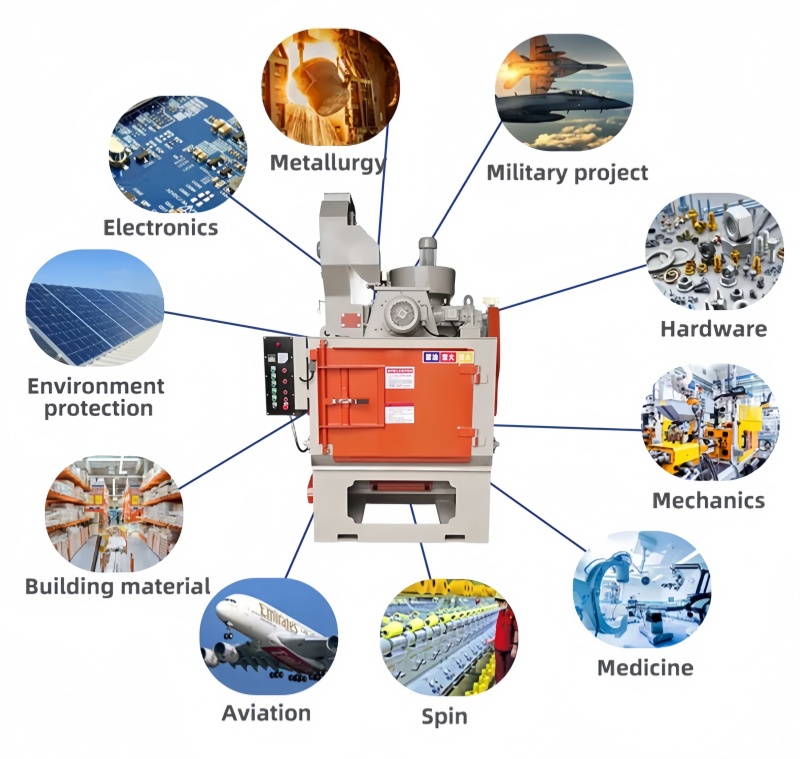

Industrial Applications

Tumble shot blasting machines are used in various industries for:

1.Foundry: Removing sand and scale from castings.

2.Forging: Deburring and surface finishing of forgings.

3.Heat Treatment: Removing oxide layers from heat-treated parts.

4.Automotive: Surface preparation of automotive components.

5.General Engineering: Cleaning and finishing of various metal parts.

These machines offer a range of capacities to suit different production needs.

In summary, tumble shot blasting machines are versatile and efficient tools for surface treatment, providing high-quality finishes and cost-effective solutions for various industrial applications.

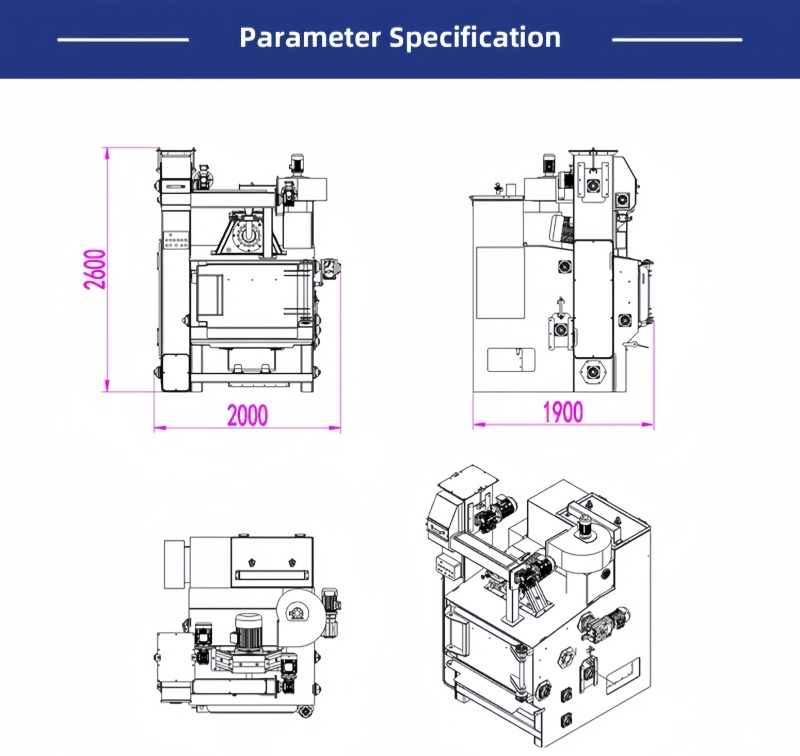

Technical Specifications

Model | Volume Capacity | Max. Weight | Blasting Capacity |

Q-324 | 0.1 m³ | 100 kg | 1*80 kg/min |

Q-326 | 0.15 m³ | 200 kg | 1*120 kg/min |

Q-3210 | 0.3 m³ | 600 kg | 1*180 kg/min |