Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

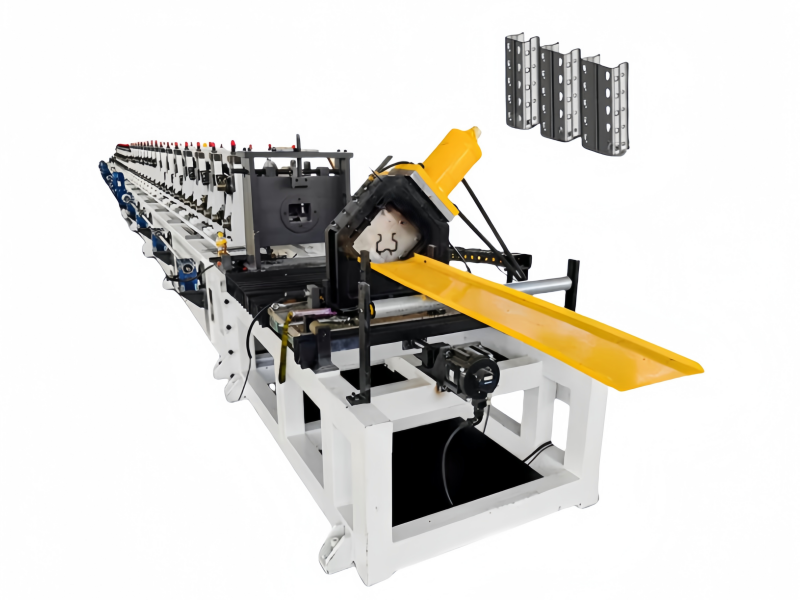

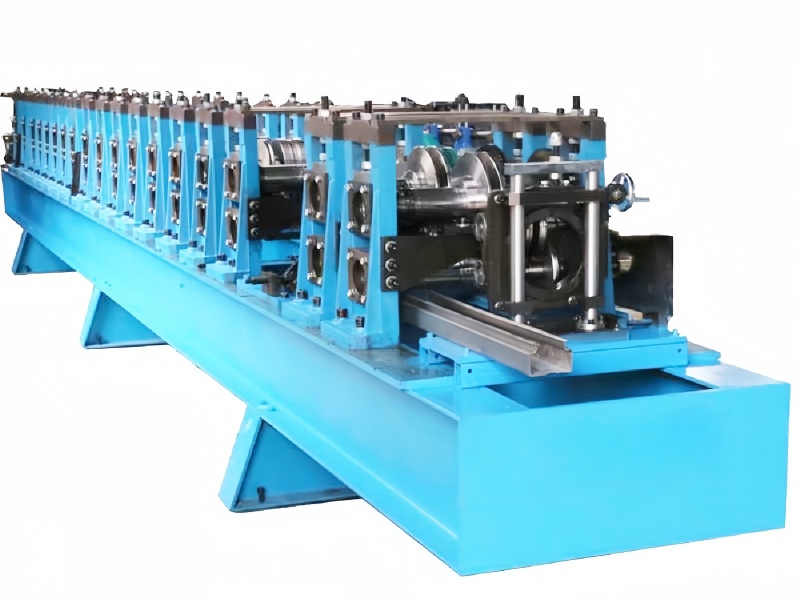

1.Name:Upright Roll Forming Machine

2.Application: Making Upright

3.It can custom-design

The Upright Roll Forming Machine is a specialized piece of industrial equipment designed to produce high-quality upright columns, typically used in warehouse shelving, storage racks, and other structural applications. Below is a detailed description of this machine, including its specifications, applications, and industry standards.

Main Components

1.Decoiler: This component unwinds the metal coil and feeds it into the machine. It often includes a hydraulic expansion mandrel to handle different coil sizes.

2.Leveling Device: This unit flattens and straightens the metal strip to ensure even feeding and improve the accuracy of the final product.

3.Servo Feeding Device: It controls the speed and accuracy of the metal strip as it moves through the machine.

4.Punching Device: This component punches holes or shapes into the metal strip as it enters the roll forming section, allowing for customized hole patterns.

5.Roll Forming Section: This is the core part of the machine, where the metal strip is gradually shaped into the desired upright profile through a series of rollers.

6.Cutting Device: It cuts the formed upright columns to the desired length, typically using hydraulic shearing.

7.Control System: Modern upright roll forming machines are equipped with PLC control systems and touchscreens for easy operation and monitoring.

Working Process

1. The metal coil is loaded onto the decoiler and fed into the machine.

2. The leveling device flattens the metal strip.

3. The servo feeding device controls the speed and accuracy of the strip.

4. The punching device creates holes or shapes as needed.

5. The roll forming section shapes the metal strip into the desired upright profile.

6. The cutting device cuts the formed upright to the specified length.

7. The finished uprights are ejected for collection or further processing.

Applications

Upright roll forming machines are widely used in the following industries:

1.Warehouse Shelving: Producing upright columns for storage racks.

2.Retail and Supermarkets: Creating shelving systems for various products.

3.Industrial Storage: Manufacturing strong and durable uprights for heavy-duty storage solutions.

4.Construction: Producing structural components for building frameworks.

Technical Specifications

1.Material Compatibility: Suitable for hot-rolled steel, cold-rolled steel, galvanized steel, stainless steel, and aluminum.

2.Material Thickness: Typically ranges from 1.5mm to 3.0mm.

3.Forming Speed: Varies from 1-3 meters per minute for some models, up to 20 meters per minute for high-speed machines.

4.Roller Stations: Machines usually have 16 to 20 roller stations.

5.Roller Material: High-quality steel such as Gcr15 or Cr12, with hardness levels of HRC58-62.

6.Power Requirements: Main motor power ranges from 15kW to 37kW, depending on the model.

7.Machine Weight: Typically between 14 to 18 tons.

8.Dimensions: Vary based on the model, but common dimensions include 8.8m x 1.2m x 1.6m.

Industry Standards

1.ISO and CE Standards: Machines are often designed to meet international standards such as ISO and CE for quality and safety.

2.FEM Standards: Some machines also comply with FEM standards, ensuring high precision and reliability.

Advantages

1.High Precision: CNC machining of rollers ensures precision performance.

2.Customization: Machines can be configured to produce a wide range of upright sizes and profiles.

3.Efficiency: Automated processes reduce labor costs and increase production speed.

4.Durability: High-quality materials and components ensure long-term reliability.

Installation and Maintenance

5.Site Planning: Requires careful planning for space, access, concrete foundations, power supply, and safety controls.

6.Maintenance: Regular maintenance is essential to ensure consistent performance and longevity.

The Upright Roll Forming Machine is a versatile and efficient solution for producing high-quality upright columns for various applications. Its precision, customization capabilities, and durability make it a valuable asset in the metalworking industry.