Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Model: MZ-5300

2.Wire Transport Way : Double Shafts

3.Shafts Length:5300mm

Introduction

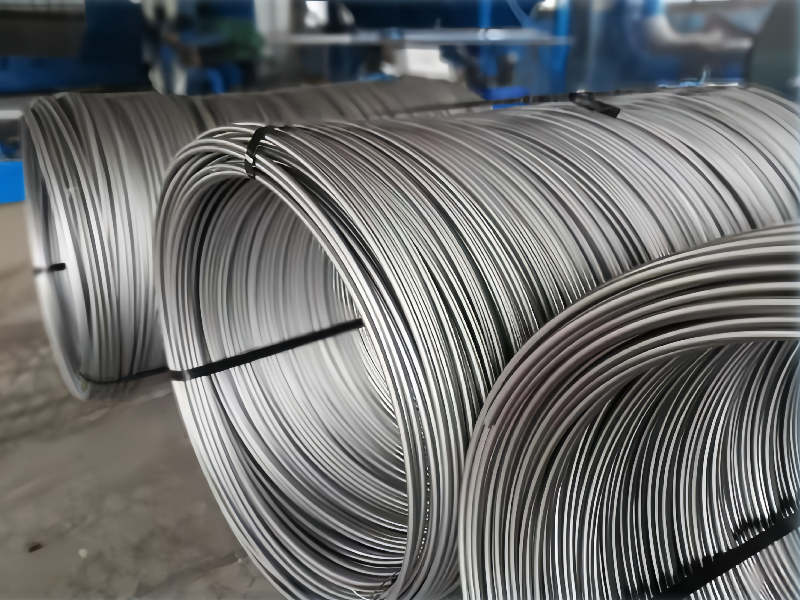

A Wire Rod Shot Blaster is a specialized industrial machine designed to clean, descale, and prepare the surfaces of wire rods through the shot blasting process. It uses high-speed abrasive media (such as steel shot or grit) to remove rust, scale, and other contaminants from wire rods, ensuring a clean and prepared surface for further processing.

Applications

Wire Rod Shot Blasters are widely used across various industries, including:

1.Steel Manufacturing: Prepares wire rods for downstream processes like drawing, coating, or galvanizing.

2.Automotive: Enhances fatigue resistance and coating adhesion for components like suspension springs and stabilizer bars.

3.Construction: Ensures reinforcement wires are durable and resistant to corrosion.

4.Aerospace: Meets stringent quality standards for high-performance materials.

5.General Manufacturing: Used for cleaning and surface preparation of wire rods for various products.

Advantages

1.Uniform Surface Treatment: Ensures all surfaces of the wire rods are evenly treated.

2.High Efficiency: Processes wire rods quickly and effectively.

3.Versatility: Suitable for a wide range of wire rod types and sizes.

4.Cost-Effective: The built-in media recovery system reduces operational costs.

5.Environmental Friendliness: Equipped with dust collection and recyclable media, minimizing environmental impact.

6.Improved Fatigue Life: Shot peening enhances the mechanical properties of wire rods.

7.Reduced Downtime: Efficient automation and design ensure minimal downtime between cycles.

Content and Structure

A typical Wire Rod Shot Blaster consists of the following key components:

1.Blast Turbines: High-speed turbines that propel abrasive media onto the wire rods.

2.Abrasive Recovery System: Collects and recycles the used abrasive media.

3.Conveyor System: Transports wire rods through the machine.

4.Dust Collection System: Removes dust and debris generated during the process.

5.Control Panel: Allows for precise control over the blasting process.

Features

1.Fully Automated Operation: Reduces manual intervention and ensures uniform cleaning.

2.High-Performance Blast Wheels: Enhance the speed and efficiency of the cleaning process.

3.Adjustable Shot Flow Rate: Customizable to meet different material requirements.

4.Dust Collection System: Maintains a clean and safe working environment.

5.Wear-Resistant Components: Prolongs the machine’s lifespan and reduces maintenance costs.

Functions

1.Surface Cleaning: Removes rust, scale, and other contaminants.

2.Surface Preparation: Prepares wire rods for coating, painting, or further processing.

3.Surface Strengthening: Enhances the fatigue resistance of wire rods through shot peening.

Working Process

1.Loading: Wire rods are fed into the machine using a conveyor or spool system.

2.Abrasive Projection: High-speed turbines blast abrasive media onto the wire surface.

3.Cleaning & Debris Removal: Rust, scale, and debris are dislodged and collected in a dust chamber.

4.Surface Finish Inspection: The cleaned wire rods undergo quality checks before further processing.

5.Unloading: Processed wire rods are ready for downstream manufacturing steps.

Working Principles

Wire Rod Shot Blasters use high-velocity steel shots or other abrasives propelled by centrifugal force from the blasting wheels to impact the wire rod surface. This process removes surface impurities and prepares the wire rod for further processing.

Maintenance and Care

1.Regular Inspection: Check the condition of the blast turbines, conveyor system, and dust collection system.

2.Abrasive Media Management: Ensure the quality and quantity of abrasive media are maintained.

3.Dust Collection System Maintenance: Regularly clean and maintain the dust collection system to prevent clogging.

4.Safety Checks: Ensure all safety guards and emergency stop buttons are functioning.

How to Choose

When selecting a Wire Rod Shot Blaster, consider the following:

1.Production Needs: Ensure the machine meets your specific production requirements.

2.High-Speed Turbines: Look for machines with efficient and durable turbines.

3.Automated Feeding Systems: Choose machines that integrate seamlessly into your production line.

4.Dust Collection and Recycling Units: Opt for machines with effective dust collection and abrasive recycling systems.

5.Adjustable Settings: Select machines that allow for precise control over blasting intensity and throughput.

Wire Rod Shot Blasters are essential for industries requiring high-quality surface treatment of wire rods. They ensure superior surface quality, improved coating adhesion, and increased durability while reducing production costs and waste.