Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

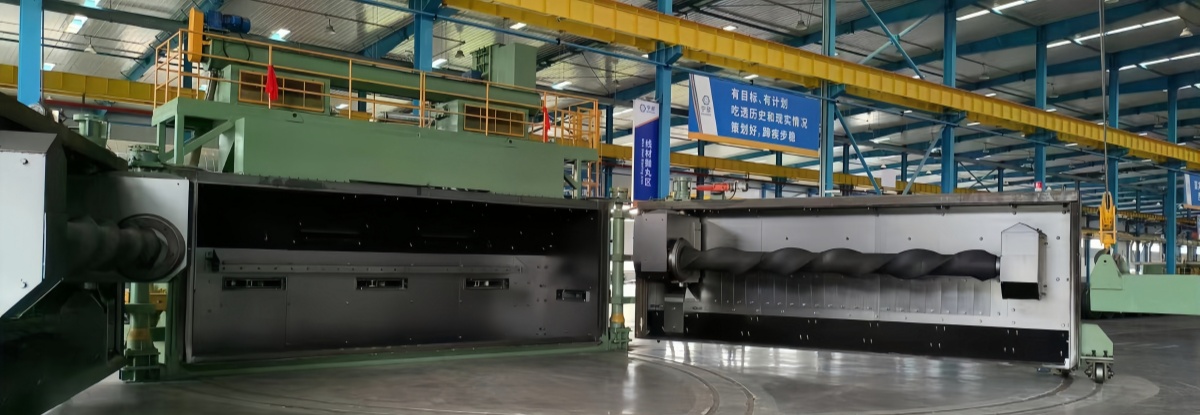

1.Model: MZ-5300

2.Wire Transport Way : Double Shafts

3.Shafts Length:5300mm

A Wire Rod Shot Blasting Machine is specialized industrial equipment designed for the surface treatment of wire rods. It uses high-velocity steel shots or other abrasive media to remove rust, scale, and other contaminants from wire rods, ensuring a clean and prepared surface for further processing. This machine is essential for enhancing surface quality, improving coating adhesion, and increasing the mechanical properties of wire rods.

Application Industries

Wire rod shot blasting machines are widely used across various industries, including:

1.Steel Manufacturing: Prepares wire rods for downstream processes like drawing, coating, or galvanizing.

2.Construction: Ensures reinforcement wires are durable and resistant to corrosion.

3.Automotive: Delivers precision for springs, cables, and other critical components.

4.Aerospace: Meets stringent quality standards for high-performance materials.

5.General Manufacturing: Used for cleaning and preparing wire rods for coating, painting, or further processing.

Advantages

1.Uniform Surface Treatment: Ensures all surfaces of the wire rods are evenly treated.

2.High Efficiency: Processes long or continuous wire rods quickly and effectively.

3.Versatility: Suitable for a wide range of wire rod types and sizes.

4.Cost-Effective: The built-in media recovery system allows for efficient reuse of abrasive material, reducing operational costs.

5.Environmental Friendliness: Equipped with dust collection and recyclable media, minimizing environmental impact.

6.Enhanced Durability: Shot peening improves the mechanical properties of wire rods, especially their fatigue resistance.

7.Reduced Downtime: Efficient automation and design ensure minimal downtime between cycles.

Content and Structure

The Wire Rod Shot Blasting Machine typically consists of the following components:

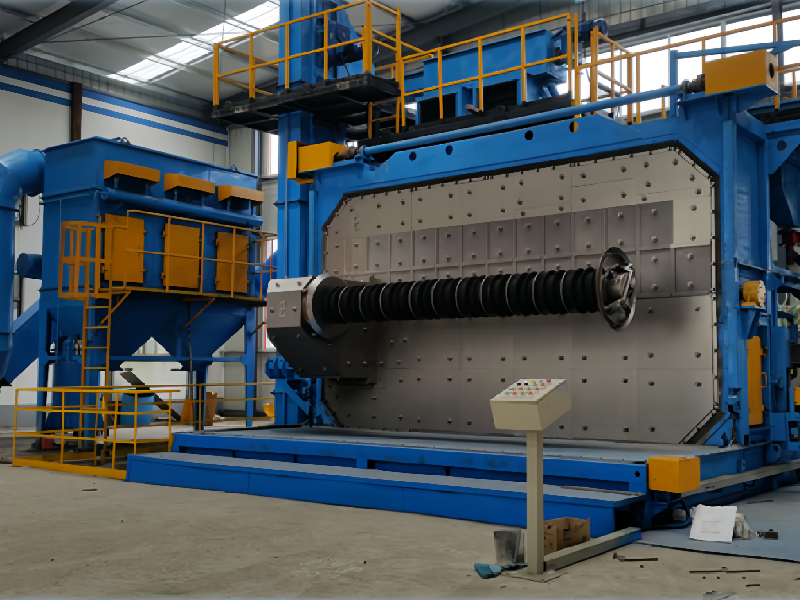

1.Blasting Chamber: The enclosed area where the shot blasting process occurs.

Blast Turbines: High-speed turbines that propel abrasive media onto the wire rods.

2.Conveyor System: Transports wire rods through the machine.

3.Abrasive Recovery System: Collects and recycles the used abrasive media.

4.Dust Collection System: Removes dust and debris generated during the process.

5.Control Panel: Allows for precise control over the blasting process.

Features

1.Automated Loading and Unloading: Ensures consistent throughput and reduces manual handling.

2.High-Speed Abrasive Cleaning: Removes rust, scale, and other contaminants effectively.

3.Full-Surface Coverage: Ensures every surface of the wire rod is exposed to the abrasive stream.

4.Dust Extraction and Abrasive Recycling: Reduces waste and ensures a clean working environment.

5.Adjustable Settings: Allows for precise control over cleaning intensity and throughput.

Working Process

1.Loading: Wire rods are fed into the machine using conveyor systems or automated feeding mechanisms.

2.Blasting: Inside the blasting chamber, turbines propel abrasive materials at high velocity onto the rod surface.

3.Surface Preparation: The rods are rotated or moved continuously to ensure full-surface coverage.

4.Dust Extraction and Abrasive Recycling: The machine’s dust collector removes debris, while the recycling system reclaims and reuses abrasives.

5.Inspection and Output: After cleaning, the rods are inspected to ensure they meet surface quality requirements.

Maintenance and Care

1.Regular Inspection: Check the condition of the blast turbines, conveyor system, and dust collection system.

2.Abrasive Media Management: Ensure the quality and quantity of abrasive media are maintained.

3.Dust Collection System Maintenance: Regularly clean and maintain the dust collection system to prevent clogging.

4.Safety Checks: Ensure all safety guards and emergency stop buttons are functioning.

How to Choose

When selecting a Wire Rod Shot Blasting Machine, consider the following:

1.Production Needs: Ensure the machine meets your specific production requirements.

2.High-Speed Turbines: Look for machines with efficient and durable turbines.

3.Automated Feeding Systems: Choose machines that integrate seamlessly into your production line.

4.Dust Collection and Recycling Units: Opt for machines with effective dust collection and abrasive recycling systems.

5.Adjustable Settings: Select machines that allow for precise control over blasting intensity and throughput.

Wire Rod Shot Blasting Machines are essential for industries requiring high-quality surface treatment of wire rods. They ensure superior surface quality, improved coating adhesion, and increased durability while reducing production costs and waste.