Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Model: MZ-5300

2.Wire Transport Way : Double Shafts

3.Shafts Length:5300mm

Wire Shot Blasting Equipment is a specialized surface treatment system designed to clean, descale, deburr, or strengthen metal wires, rods, cables, or continuous wire products using high-velocity abrasive media (e.g., steel shot, grit, or ceramic beads). It is widely used in industries requiring precise surface preparation for corrosion resistance, coating adhesion, or fatigue life enhancement.

Applications

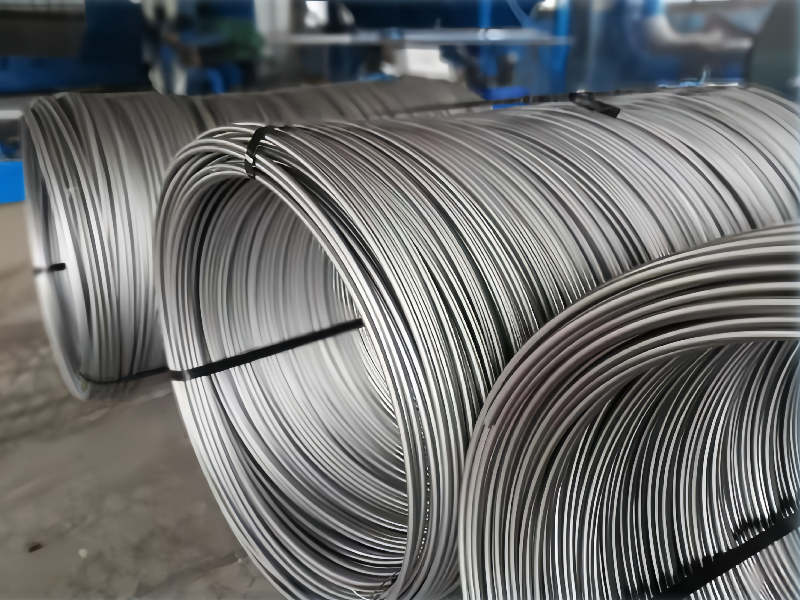

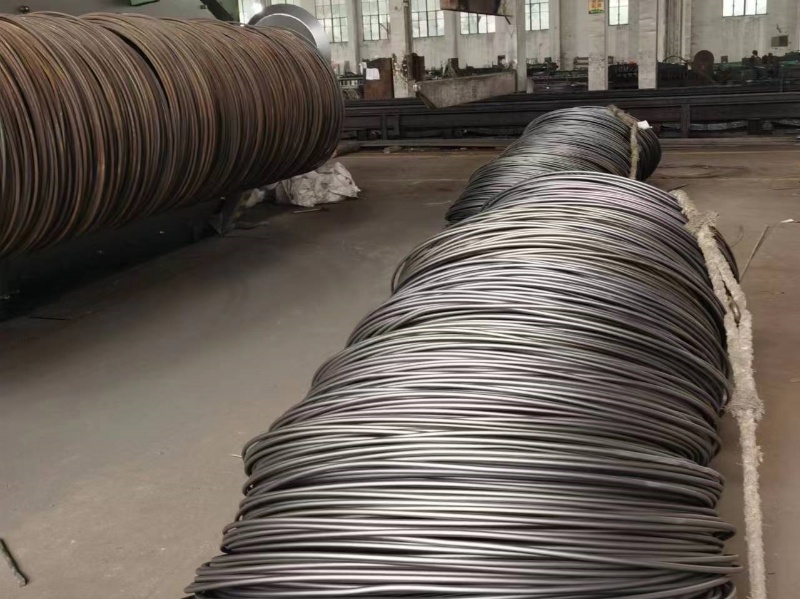

Wire Manufacturing: Cleans oxide layers and scales from steel wires before drawing or galvanizing.

1.Automotive: Processes suspension cables, spring wires, and fastener rods.

2.Construction: Prepares reinforcement bars (rebar) and pre-stressed concrete wires.

3.Aerospace: Treats high-tensile wires for aircraft cables and components.

4.Medical: Polishes surgical wires and implants for biocompatibility.

Advantages

✔ Uniform Surface Treatment: Ensures 360° coverage of wire surfaces.

✔ High Efficiency: Processes continuous wires at speeds up to 60 m/min.

✔ Eco-Friendly: Recyclable abrasives reduce waste vs. chemical cleaning.

✔ Automation: Integrates with in-line production for minimal downtime.

4. Equipment Structure & Components

Component | Function |

Blasting Chamber | Enclosed area where abrasives impact the wire; lined with wear-resistant materials. |

Abrasive Wheel | High-speed turbine propels abrasives (e.g., steel shot) at 60–100 m/s. |

Wire Feeding System | Guides wires through the chamber via motorized rollers or conveyor belts. |

Abrasive Recovery | Cyclone separators and sieves recycle reusable media. |

Dust Collector | Removes particulate debris to meet environmental standards (e.g., OSHA). |

Control Panel | PLC/HMI adjusts speed, abrasive flow, and blast pressure. |

Key Features

1.Adjustable Parameters: Blast angle, wire speed, and abrasive density tailored to wire diameter (0.5–20 mm).

2.Multi-Stage Blasting: Optional secondary blasting units for complex profiles.

3.Corrosion-Resistant Design: Stainless steel or polyurethane-lined components for longevity.

Functional Capabilities

1.Descaling: Removes mill scale and rust from hot-rolled wires.

2.Deburring: Eliminates sharp edges after cutting or stamping.

3.Peening: Enhances fatigue strength via compressive stress induction.

4.Surface Profiling: Creates anchor patterns for better coating adhesion.

Workflow

1.Loading: Wire coils are fed into the uncoiler.

2.Straightening: Leveling units remove bends/kinks.

3.Blasting: Wires pass through the chamber while abrasives treat the surface.

4.Abrasive Recovery: Media is filtered and recycled.

5.Inspection: Treated wires are checked for surface quality (e.g., Sa 2.5 cleanliness).

6.Coiling/Cutting: Finished wires are coiled or cut to length.

Operational Guidelines

1.Abrasive Selection: Steel shot (S230–S660) for heavy descaling; glass beads for polishing.

2.Safety: Operators must wear PPE; equipment includes emergency stops and interlocks.

3.Compliance: Meets ISO 8501-1 (surface cleanliness) and ASTM E11 (abrasive standards).

Maintenance & Care

1.Daily: Check abrasive levels and dust collector filters.

2.Weekly: Inspect turbine blades and liner wear.

3.Monthly: Lubricate bearings and calibrate sensors.

4.Annual: Overhaul electrical systems and replace worn components.

How to Choose the Right Equipment?

1.Wire Specifications: Diameter, material (steel/aluminum), and required surface finish (e.g., Ra ≤ 1.6 µm).

2.Production Volume: Throughput (tons/hour) and automation needs (e.g., robotic handling).

3.Abrasive Type: Steel shot for durability; ceramic beads for delicate wires.

4.Certifications: CE, ISO 9001, or industry-specific standards (e.g., NADCAP for aerospace).

Conclusion

Wire Shot Blasting Equipment is critical for ensuring the durability and performance of metal wires in high-stress applications. Advanced models from manufacturers like MIZHI Technology offer customizable solutions with IoT integration for real-time monitoring.

Need a quote or technical specs? Let us know your wire parameters!