Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Model: MZ-4350

2.Wire Transport Way : Double Shafts

3.Shafts Length:4350mm

A Wire Shot Blasting Machine is a specialized industrial system designed to clean, descale, deburr, or enhance the surface properties of metal wires, rods, cables, and continuous wire products using high-velocity abrasive media. This equipment is critical in industries requiring precise surface preparation for improved durability, corrosion resistance, or coating adhesion.

Key Features

1.Target Materials: Steel, stainless steel, aluminum, and alloy wires (diameter: 0.5–20 mm).

2.Abrasive Media: Steel shot (S230–S660), glass beads, ceramic grit, or aluminum oxide.

3.Automation: PLC-controlled operation with adjustable parameters (speed, abrasive flow, blast angle).

4.Throughput: Processes wires at speeds up to 60 meters per minute.

5.Durability: Wear-resistant liners (e.g., manganese steel, polyurethane) for extended lifespan.

Applications

1.Wire Manufacturing: Removes mill scale, rust, and oxides from hot-rolled wires before galvanizing or drawing.

2.Automotive Industry: Treats suspension cables, spring wires, and fastener rods for fatigue resistance.

3.Construction: Prepares reinforcement bars (rebar) and pre-stressed concrete wires.

4.Aerospace: Processes high-tensile wires for aircraft cables and critical components.

5.Medical Devices: Polishes surgical wires and implants to ensure biocompatibility.

Advantages

1.Uniform Surface Treatment: 360° coverage ensures consistent cleaning and profiling.

2.Eco-Friendly: Recyclable abrasives reduce waste vs. chemical cleaning methods.

3.High Efficiency: Continuous processing minimizes downtime and labor costs.

4.Enhanced Durability: Shot peening induces compressive stresses, improving fatigue life.

5.Customizable: Adjustable settings for wire diameter, material type, and surface finish requirements.

Equipment Structure

Component | Function |

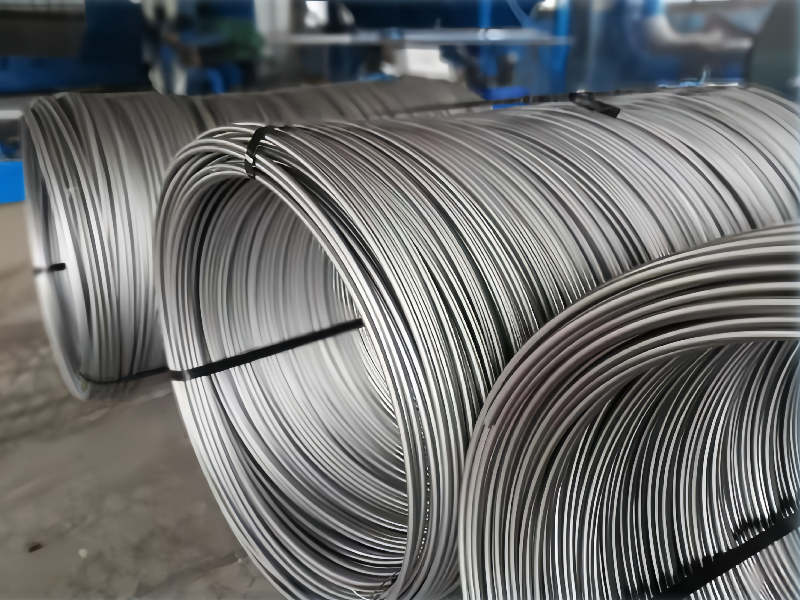

Uncoiler/Feeder | Feeds wire coils into the machine. |

Straightening Unit | Removes bends and kinks for uniform blasting. |

Blasting Chamber | Enclosed area where abrasives impact the wire surface. |

Abrasive Propulsion System | High-speed turbines or compressed air to accelerate abrasives (60–100 m/s). |

Abrasive Recovery System | Cyclones and sieves recycle reusable media; separates dust and debris. |

Dust Collector | Filters airborne particles to meet environmental regulations (e.g., OSHA). |

Control Panel | PLC and HMI interface for real-time monitoring and adjustments. |

Re-coiler/Cutter | Collects or cuts treated wires to specified lengths. |

Workflow

1.Loading: Wire coils are mounted on the uncoiler.

2.Straightening: Wires pass through rollers to eliminate deformities.

3.Blasting: Abrasives are propelled onto the wire surface in the chamber.

4.Abrasive Recovery: Media is filtered, cleaned, and recycled.5.Surface Inspection: Treated wires are checked for cleanliness (e.g., Sa 2.5 standard).

6.Output: Wires are re-coiled or cut for packaging or further processing.

Technical Specifications

Parameter | Details |

Wire Diameter Range | 0.5–20 mm |

Blasting Speed | 10–60 m/min |

Abrasive Consumption | 50–200 kg/hour (depends on wire size) |

Power Requirement | 15–50 kW (380V/50Hz or customizable) |

Compliance Standards | ISO 8501-1, ASTM E11, CE, OSHA |

Maintenance Guidelines

1.Daily: Check abrasive levels, inspect dust collector filters, and clean sensors.

2.Weekly: Lubricate bearings, inspect turbine blades for wear, and test safety interlocks.

3.Monthly: Replace worn liners, calibrate speed sensors, and inspect electrical systems.

4.Annual: Overhaul the recovery system and replace critical wear parts (e.g., seals).

How to Choose the Right Machine?

1.Wire Specifications: Diameter, material type, and required surface finish (e.g., Ra ≤ 1.6 µm).

2.Production Volume: Select machines with throughput matching your output (e.g., 5–10 tons/day).

3.Abrasive Type: Steel shot for heavy descaling; ceramic beads for delicate polishing.

4.Automation Needs: Opt for IoT-enabled models for remote monitoring and predictive maintenance.

5.Certifications: Ensure compliance with industry standards (e.g., NADCAP for aerospace).

Conclusion

A Wire Shot Blasting Machine is indispensable for industries requiring high-quality surface treatment of metal wires. By combining automation, precision, and eco-friendly practices, this equipment ensures wires meet stringent performance and durability standards.

Need a tailored solution? Share your wire specifications (diameter, material, production volume) for a customized recommendation!