Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

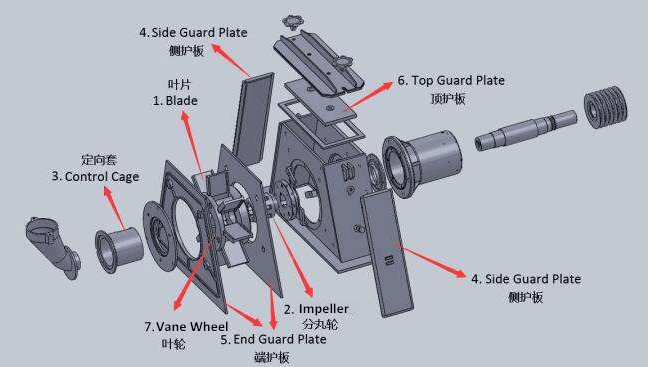

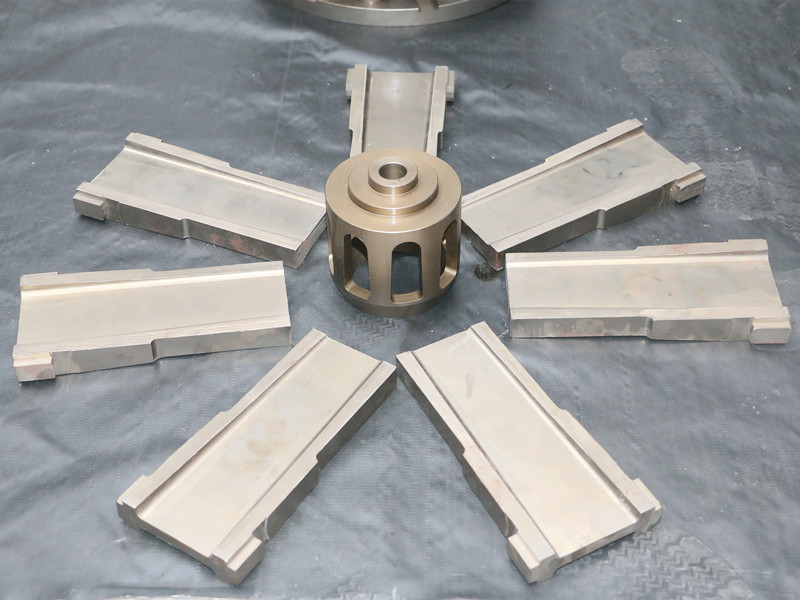

One vane wheel, 8 pieces of high-hardness and wear-resistant precision CNC machining blades, directly inserted type, installed on the vane wheel; A Control cage and impeller control the pellet throwing direction and preaccelerate the pellet feeding respectively.

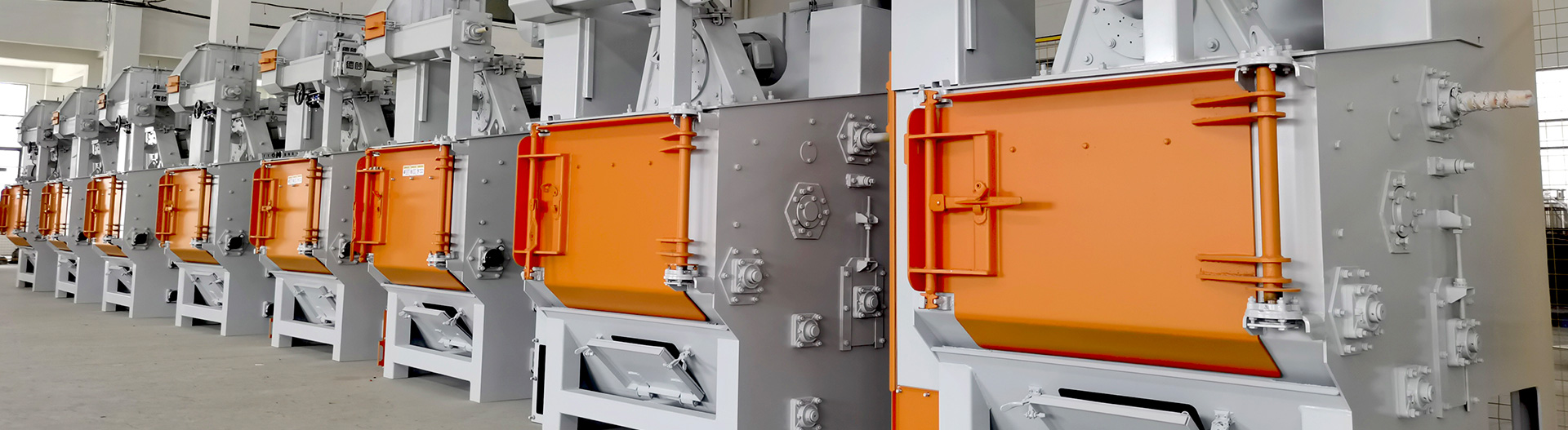

All kinds of shot blasting machines

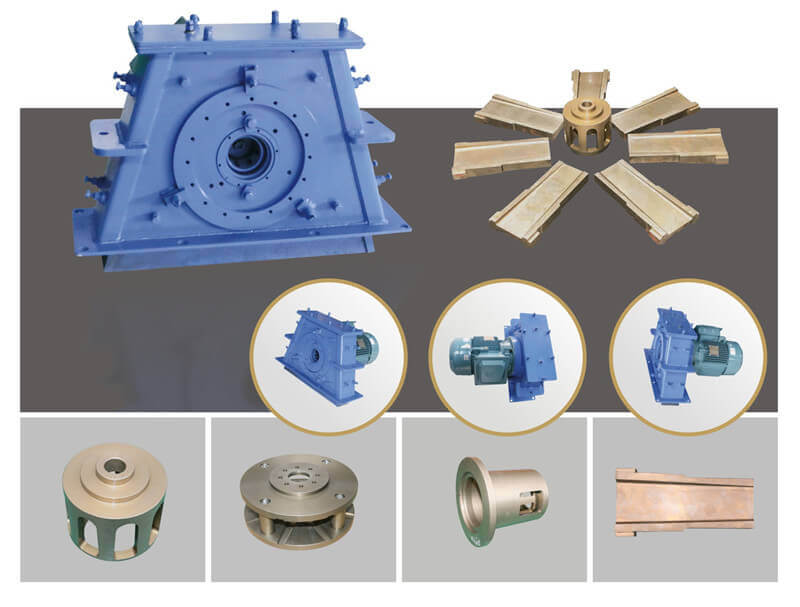

MIZHI direct drive blast wheel is designed to perform at optimal levels for a very long life and for simple maintenance. Made of wear resistant die steel material , reliable performance. Each wheel consists of eight replaceable blades mounted to a balanced impeller. Blades are balanced in pairs and installed to maintain low vibrations.

This is a unique designed blast wheel with exceptionally tight tolerances and built-in specialist superior die steel.

Due to the higher value materials and the high specification machining costs of these materials, the initial investment and cost of component wear parts are more highly valued than that of the casting blast wheel.

Blast wheel box built-in manganese 13 steel.

Covered in laminated and hardened die steel.

A direct coupling by an ABB brand electric motor

Modern adjustment system that blocks the mounting in the wrong position.

Longer life and productivity, compared to others.

Improve your Blast Performance

Reduced noise level

Low maintenance costs, Save your money

Blade

1. Adopting die steel CNC precise processing, processing accuracy reaches ± 0.01; weight tolerance is ± 0.2g; with Uniform wear, good dynamic balance.

2. Adopting low pressure vacuum heat treatment after CNC precision machining.

3. Uselife:1800-3500 hours(Using abrasive:S230,Hardness:HRC40-50).

4. QTY:8 Pieces.

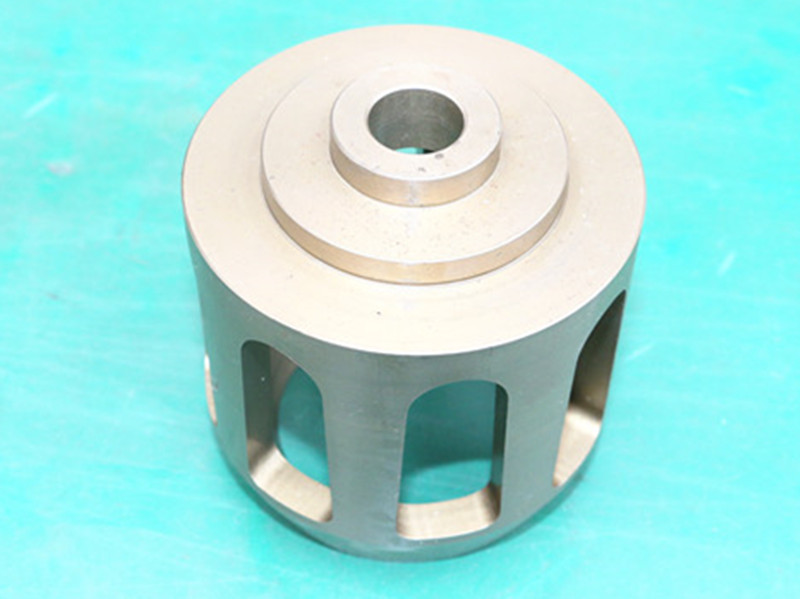

Vane Wheel

1. Adopting die steel CNC precise processing, processing accuracy reaches ± 0.01.

2. Adopting low pressure vacuum heat treatment after CNC precision machining, Surface hardness can reach HRC58-62.

3. Uselife:3000-6000 hours(Using abrasive:S230,Hardness:HRC40-50).

4. QTY:1 PC.

Impeller

1. Adopting die steel CNC precise processing, processing accuracy reaches ± 0.01; with Uniform wear, good dynamic balance.

2. Adopting low pressure vacuum heat treatment after CNC precision machining.

3. Uselife:2000-3000 hours(Using abrasive:S230,Hardness:HRC40-50).

4. QTY: 1 PC

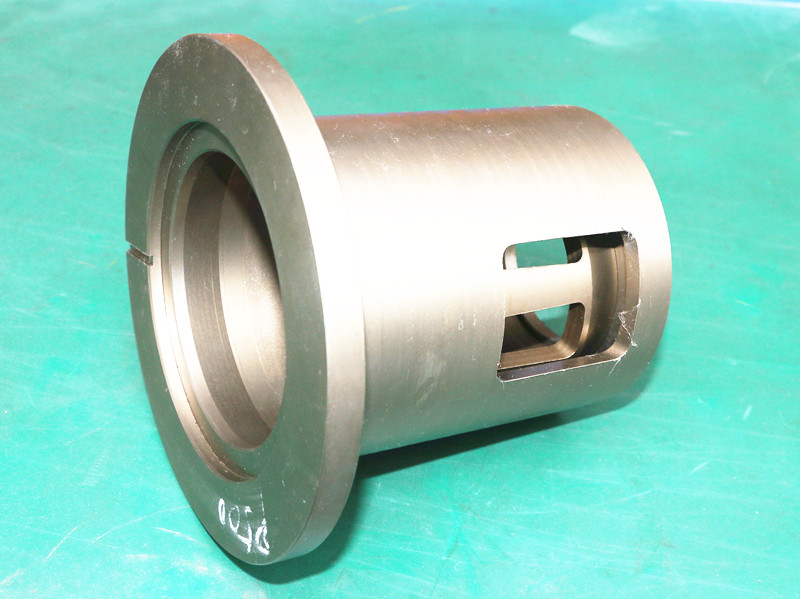

Control Cage

1. Adopting die steel CNC precise processing, processing accuracy reaches ± 0.01; with Uniform wear, good dynamic balance.

2. Adopting low pressure vacuum heat treatment after CNC precision machining.

3. Uselif:2000-3000 hours(Using abrasive:S230,Hardness:HRC40-50).

4. QTY: 1 PC.

Side Guard

1. Adopting die steel CNC precise processing, processing accuracy reaches ± 0.01.

2. Adopting low pressure vacuum heat treatment after CNC precision machining.

3. Uselif:3000-5000 hours(Using abrasive:S230,Hardness:HRC40-50).

4. QTY: 2 PCS

Electric motor

1. Excellent controllable manufacturing process;

2. Good sealing and dynamic balance;

3. Stable and reliable performance.

4. ABB brand made in Switzerland