Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

A foundry is an industrial plant where metal is melted and cast into specific shapes by pouring it into a mold. The process itself is centuries old. Today, approximately 90% of all manufactured goods depend on metal castings for component parts, with cars and trucks being the largest market. Aluminum, iron, and steel are the most common metals processed in foundries but other non-ferrous metals are also used for casting, or as alloys added to steel.In simplified terms, a foundry is a factory where castings are produced by melting metal, pouring liquid metal into a mold, then allowing it to solidify. Even if you have never been to a foundry, or even know what one looks like, you are surrounded by the metal castings they produce. There is a good chance that you are reading this less than 10 feet away from one.Foundries don’t just produce metal products for engine, railroad, or pipe components. They also form components for machines that are required to make many of the essential consumer products we depend on. 90 percent of all manufactured goods rely on metal castings.

1.MIZHI can provide surface cleaning and spray production lines for foundry parts.

Catenary pass type shot blasting machine

1. Model: MCT-1027P11-16 (Select model according to product size).

2. Applicable maximum part size: length: 2800mm, width: 400mm, height: 1000mm

3. Applicable maximum part weight: 2T.

4. Blast wheel QTY:16 PCS.

5. Blast wheel power:11Kw/pcs.

6. Blast wheel motor:ABB.

7. Semi-automatic flow control valve: 16 sets.

8.Operation mode: fully automatic.

9.Shot blasting room entrance size: width: 1000mm, height: 2800mm.

10. Delivery method: The chain automatically transmits.

11.PLC:Siemens.

12.Touch screen: Siemens.

Hanger type shot blasting machine

1. Model:MHB2-1717P11-3 (Select model according to product size).

2. Applicable maximum part size Dia:1700mm,Height:1700mm。

3. Applicable maximum part weight: 2T.

4. Blast wheel QTY:3 pcs.

5. Blast wheel power:11Kw/pcs.

6. Blast wheel motor:ABB.

7. Semi-automatic flow control valve:3 sets.

8.Operation mode: fully automatic.

9.Delivery method: Double track with double racks.

10. Automatic double door opening.

11.PLC:Siemens.

12.Touch screen: Siemens.

Wire mesh through type shot blasting machine

1. Model:MND-1030P11-4 (Select model according to product size).

2. Applicable maximum part size:width:1000mm,height:300mm。

3. Applicable maximum part weight: 1T.

4. Blast wheel QTY:4pcs.

5. Blast wheel power:11Kw/pcs.

6. Blast wheel motor:ABB.

7. Semi-automatic flow control valve:4sets.

8.Operation mode: fully automatic.

9.Delivery method:Mesh belt conveyor

10. Shot blasting room entrance:width:1062mm,height:300mm。

11.PLC:Siemens.

12.Touch screen: Siemens.

Wet dust collector

1. Model:MWDC-100(Explosion-proof).

2. Equipped with above mentioned shot blasting machine

3. Dust fan power:22Kw.

4. Air volum:≤9000m3/h.

5. Air pressure≤7000Pa/h.

6. Noise≤80db.

7. Tuyere diameter:φ320mm.

8. Dust emission:30mg/m3.

9.Scraper motor:0.37Kw.

10. Pump motor:7.5Kw.

11.PLC:Siemens.

12.Touch screen: Siemens.

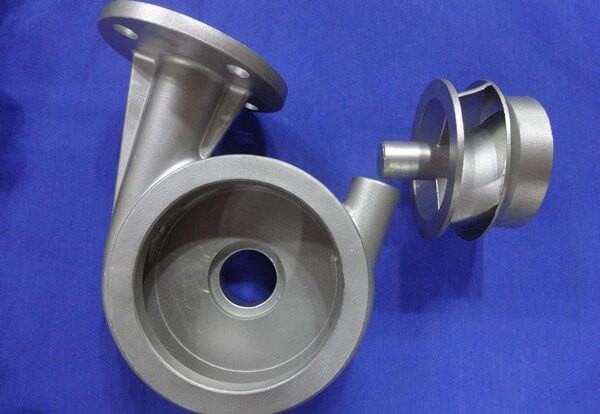

Sand casting products

一. Detailed informtaion from customer side

1. Single piece length (both maximum and minimum lengths are required).

2. Single piece width (both maximum and minimum width are required).

3. Part thickness.

4. Single piece weight (both maximum and minimum weight are required).

5. Part material.

6. he processing of the parts before shot blasting.

7.Requirements for surface cleanliness and roughness of parts.

8.Production requirements (daily production / monthly production / annual output).

9. Requirements for the dust collector

10.Provision of the height and space dimensions of the plant of the equipment.

11.Other requirements of customer side.

Precision casting products

一. Detailed informtaion from customer side

1. Single piece length (both maximum and minimum lengths are required).

2. Single piece width (both maximum and minimum width are required).

3. Part thickness.

4. Single piece weight (both maximum and minimum weight are required).

5. Part material.

6. he processing of the parts before shot blasting.

7.Requirements for surface cleanliness and roughness of parts.

8.Production requirements (daily production / monthly production / annual output).

9. Requirements for the dust collector

10.Provision of the height and space dimensions of the plant of the equipment.

11.Other requirements of customer side.

Aluminum die casting

一. Detailed informtaion from customer side

1. Single piece length (both maximum and minimum lengths are required).

2. Single piece width (both maximum and minimum width are required).

3. Part thickness.

4. Single piece weight (both maximum and minimum weight are required).

5. Part material.

6. he processing of the parts before shot blasting.

7.Requirements for surface cleanliness and roughness of parts.

8.Production requirements (daily production / monthly production / annual output).

9. Requirements for the dust collector

10.Provision of the height and space dimensions of the plant of the equipment.

11.Other requirements of customer side.