Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

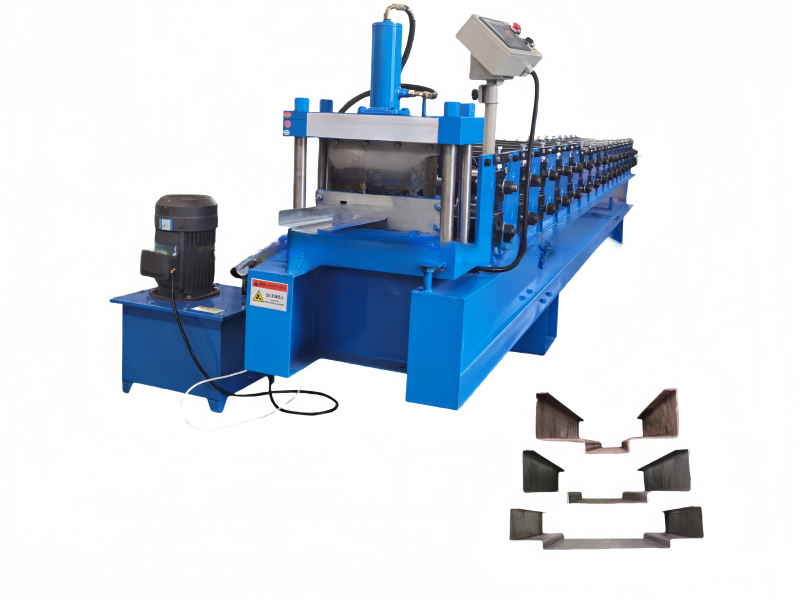

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

Our company is well received by customers with perfect solutions, good product quality, performance, and after-sales

1.Model No.: TL

2.Applications: Pressing Line/Metal Stamping Line

3.Applicable Coil Width: 20mm-1300mm

4.Applicable Coil Thickness: 0.4-2.2mm

5.Speed: 15m/min

6.Suitable for vary kind of coil material, such as Galvanized steel, Stainless steel, CR Steel, HR Steel, Galvanized steel, Stainless steel,Aluminum, Cooper etc.

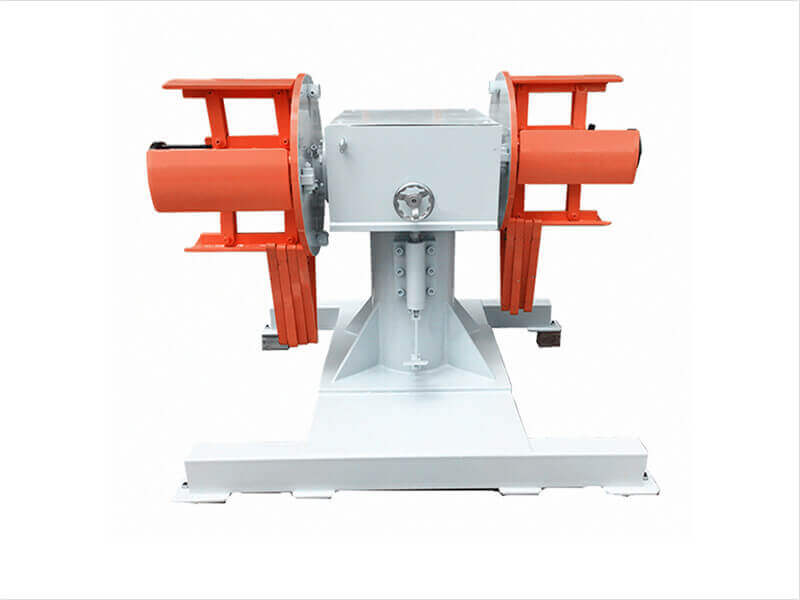

1.Model No.: HS

2.Applications: Pressing Line/Metal Stamping Line

3.Applicable Coil Width: 600mm

4.Applicable Coil Thickness: 0.5-4.5mm/1.0-6.0mm

5.Speed: 15m/min

6.Suitable for vary kind of coil material, such as Galvanized steel, Stainless steel, CR Steel, HR Steel, Galvanized steel, Stainless steel,Aluminum, Cooper etc.

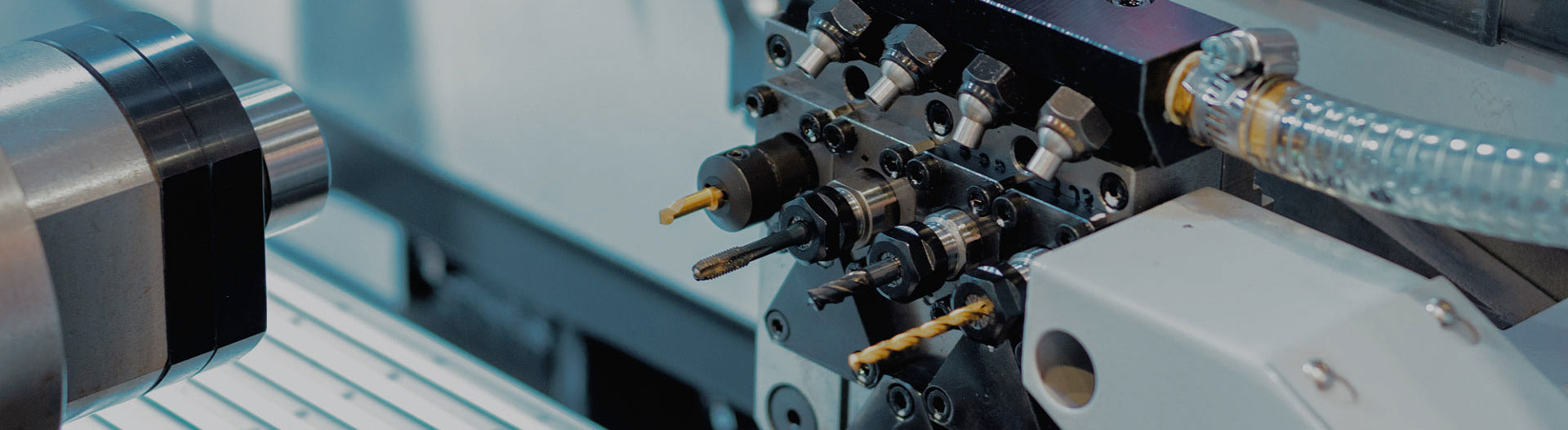

1.Model:APA

2.Name:High precision power press

3.Capacity:15-110T

4.Stroke:60-180mm

5.Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produce the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal.

Metal sheet press feed line is a metal forming process widely used to produce parts for various industries, such as automotive stamping, electronics stamping and appliances stamping and etc.